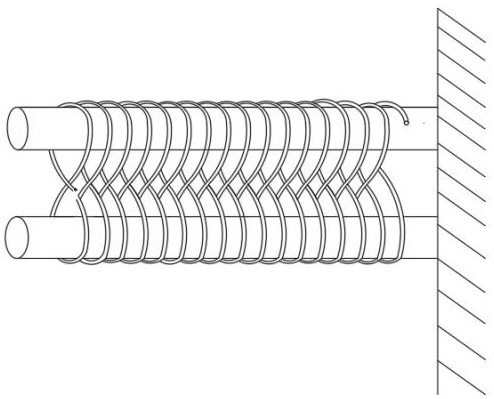

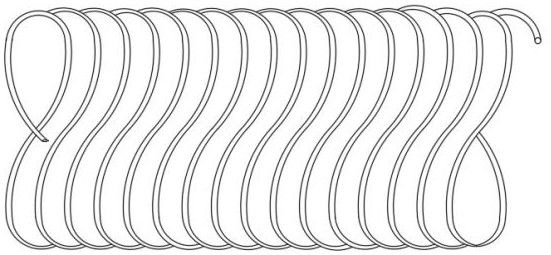

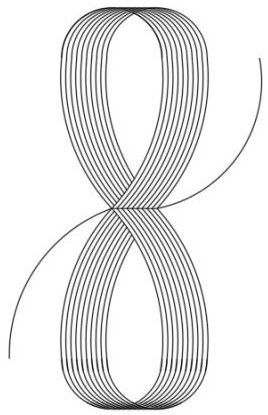

New energy automobile 8-shaped telescopic easy-to-store charging wire manufacturing process

A new energy vehicle and manufacturing process technology, which is applied in the field of 8-shaped retractable and easy-to-storage charging lines for new energy vehicles, can solve the problems of twisted and bulging charging lines, inconvenient storage, and high cost, and achieve the goal of reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Specifically include the following steps:

[0036] S1. Preparation: After the linear extrusion is completed, use glass fiber or nylon wire to weave, then apply silicone oil, and dry at low temperature. After waiting for cooling, place the entire axis of cable on the lifting frame of the wire cutting machine and fix it. Raise to the highest point, then pass the first end of the cable through the fixed pulleys and extend to the cutter of the wire cutting machine;

[0037] S2. Strip cutting: set the parameters of the wire cutting machine according to the production drawings, and the skin must not be scratched. The calculation formula for strip cutting is: L=2(L1+L2), where L1=5πd, L2=2*L1= 10πd, then cut the length of the cable according to the cutting formula, and reserve a certain length at both ends;

[0038] S3. Rolling: Manually roll the cut wire into a coil, and wrap the end of the reserved wire length at both ends of the cable with PE film to fix it, and place it i...

Embodiment 2

[0048] Specifically include the following steps:

[0049] S1. Preparation work: After the linear extrusion is completed, weave it with glass fiber or nylon wire, then apply silicone oil, and dry it at low temperature. After cooling down, place the entire axis cable on the lifting frame of the wire cutting machine and fix it. And lift to the highest point, then pass the first end of the cable through the fixed pulley in turn and extend to the cutter of the wire cutting machine;

[0050] S2. Strip cutting: set the parameters of the wire cutting machine according to the production drawings, and the skin must not be scratched. The calculation formula for strip cutting is: L=2(L1+L2), where L1=5πd, L2=2*L1= 10πd, then cut the length of the cable according to the cutting formula, and reserve a certain length at both ends;

[0051]S3. Rolling: Manually roll the cut wire into a coil, and wrap the end of the reserved wire length at both ends of the cable with PE film to fix it, and pl...

Embodiment 3

[0061] Specifically include the following steps:

[0062] S1. Preparation work: After the linear extrusion is completed, weave it with glass fiber or nylon wire, then apply silicone oil, and dry it at low temperature. After cooling down, place the entire axis cable on the lifting frame of the wire cutting machine and fix it. And lift to the highest point, then pass the first end of the cable through the fixed pulley in turn and extend to the cutter of the wire cutting machine;

[0063] S2. Strip cutting: set the parameters of the wire cutting machine according to the production drawings, and the skin must not be scratched. The calculation formula for strip cutting is: L=2(L1+L2), where L1=5πd, L2=2*L1= 10πd, then cut the length of the cable according to the cutting formula, and reserve a certain length at both ends;

[0064] S3. Rolling: Manually roll the cut wire into a coil, and wrap the end of the reserved wire length at both ends of the cable with PE film to fix it, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com