Photovoltaic power generation window with high wear resistance

A technology of photovoltaic power generation and high wear resistance, applied in photovoltaic power generation, photovoltaic modules, current collectors, etc., can solve problems such as poor wear resistance and short service life, achieve good adhesion, good space repulsion, and increase affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

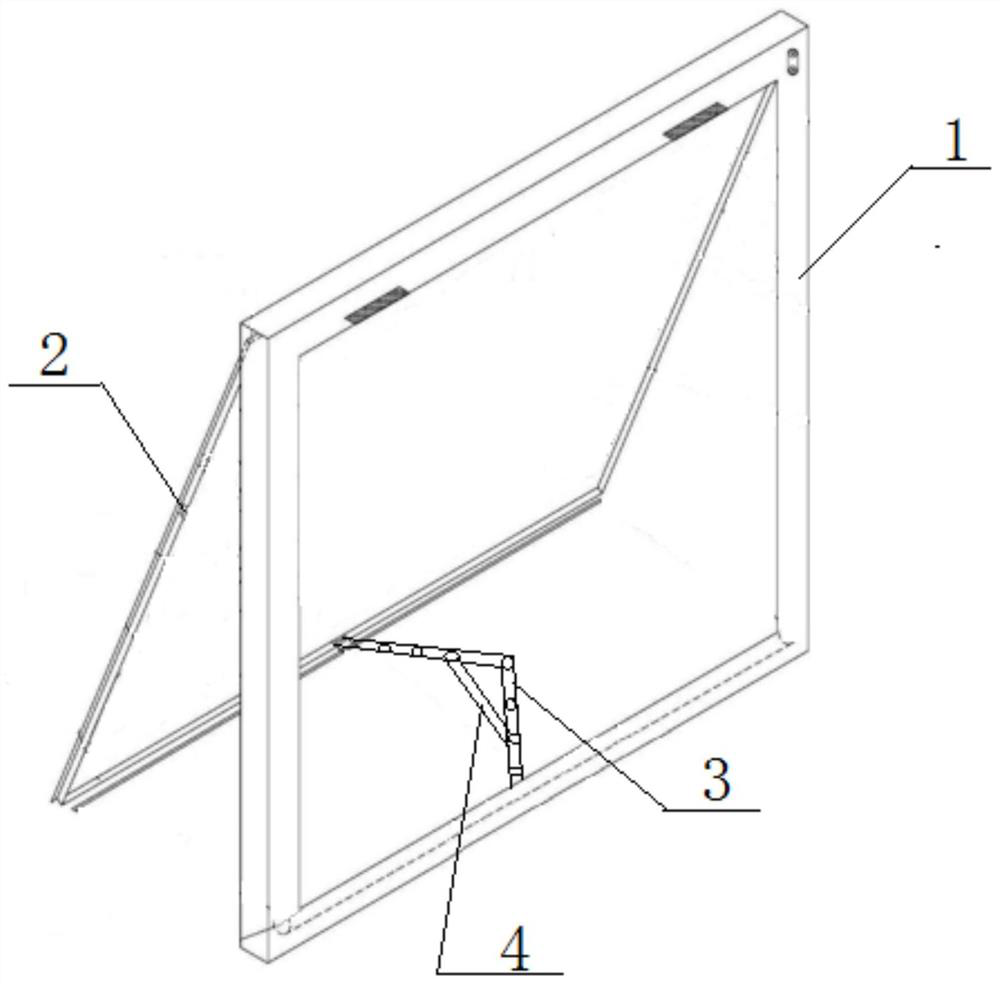

[0035] A highly wear-resistant photovoltaic power generation window provided by this embodiment has a structure such as figure 1 As shown, it includes window frame 1, window 2, solar photovoltaic panel, control circuit board, battery, inverter, load connection port and support rod, and a layer of wear-resistant layer is coated on window frame 1, wherein:

[0036] The window 2 is composed of a solar photovoltaic panel and an insulating glass arranged at the bottom of the solar photovoltaic panel;

[0037] One end of the window 2 is rotatably connected to the window frame 1, the control circuit board, the storage battery, and the inverter are respectively installed in the window frame 1, the load connection port is placed on the inner surface of the window frame 1, and the solar photovoltaic panel in the window 2 is connected to the window frame 1. The control circuit board is electrically connected, one side of the control circuit board is connected to the battery and the DC co...

Embodiment 2

[0052] A highly wear-resistant photovoltaic power generation window provided by this embodiment has a structure such as figure 1 As shown, it includes window frame 1, window 2, solar photovoltaic panel, control circuit board, battery, inverter, load connection port and support rod, and a layer of wear-resistant layer is coated on window frame 1, wherein:

[0053] The window 2 is composed of a solar photovoltaic panel and an insulating glass arranged at the bottom of the solar photovoltaic panel;

[0054] One end of the window 2 is rotatably connected to the window frame 1, the control circuit board, the storage battery, and the inverter are respectively installed in the window frame 1, the load connection port is placed on the inner surface of the window frame 1, and the solar photovoltaic panel in the window 2 is connected to the window frame 1. The control circuit board is electrically connected, one side of the control circuit board is connected to the battery and the DC co...

Embodiment 3

[0069] A highly wear-resistant photovoltaic power generation window provided by this embodiment has a structure such as figure 1 As shown, it includes window frame 1, window 2, solar photovoltaic panel, control circuit board, battery, inverter, load connection port and support rod, and a layer of wear-resistant layer is coated on window frame 1, wherein:

[0070] The window 2 is composed of a solar photovoltaic panel and an insulating glass arranged at the bottom of the solar photovoltaic panel;

[0071] One end of the window 2 is rotatably connected to the window frame 1, the control circuit board, the storage battery, and the inverter are respectively installed in the window frame 1, the load connection port is placed on the inner surface of the window frame 1, and the solar photovoltaic panel in the window 2 is connected to the window frame 1. The control circuit board is electrically connected, one side of the control circuit board is connected to the battery and the DC co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com