Preparation method and application of graphdiyne in-situ grown metal organic framework material

A metal-organic framework, in-situ growth technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high cost and low reserves of precious metal catalysts, and achieve catalytic activity and stability. Improve and solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

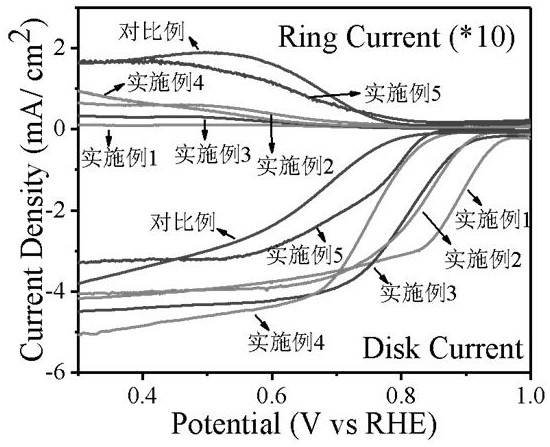

Embodiment 1

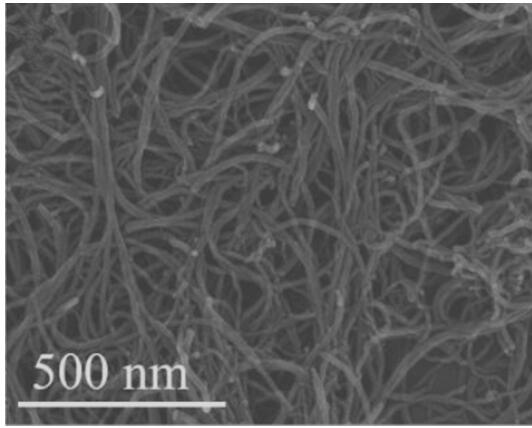

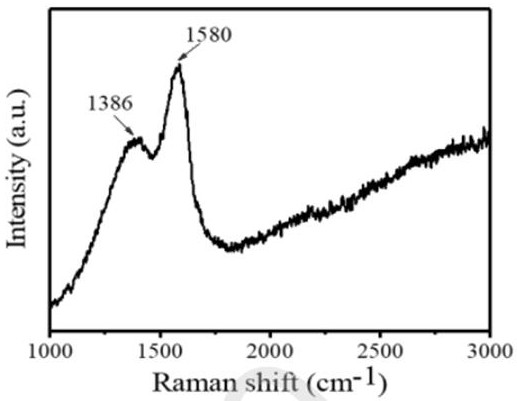

[0028] (1) Graphyne and Fe(NO 3 ) 3 9H 2 O was sonicated in ethanol until uniformly dispersed, and graphyne adsorbing metal salts was obtained by rotary evaporation drying technology; the ultrasonic power was 220W, and the ultrasonic time was 20min.

[0029] (2) NH with a mass ratio of 3:1 to graphyne 2 -H 2 BDC and the product of step (1) were reacted in a reaction kettle at 120 °C for 72 h under the condition of dimethylformamide solvent, cooled, and washed to obtain a metal-organic framework material grown on graphyne in situ;

[0030] (3) Under a nitrogen atmosphere, the temperature was raised to 900°C at a heating rate of 5°C / min and kept for 3h, then cooled, and pickled with 2M HCl solution at 90°C for 24h to obtain a graphyne in situ growth metal organic framework material.

Embodiment 2

[0032] (1) Graphyne and Fe(NO 3 ) 3 9H 2 O was sonicated in ethanol until uniformly dispersed, and graphyne adsorbing metal salts was obtained by rotary evaporation drying technology; the ultrasonic power was 280W, and the ultrasonic time was 10min.

[0033] (2) NH with a mass ratio of 2:1 to graphyne 2 -H 2 BDC and the product of step (1) were reacted in a reaction kettle at 125°C for 70 h under the condition of dimethylformamide solvent, cooled down, and washed to obtain a metal-organic framework material grown on graphyne in situ;

[0034] (3) Under a nitrogen atmosphere, the temperature was raised to 950 °C at a heating rate of 5 °C / min and kept for 2.5 h, then cooled, and pickled with 2.5 M HCl solution at 95 °C for 22 h to obtain a graphyne in situ growth metal organic framework material .

Embodiment 3

[0036] (1) Graphyne and Fe(NO 3 ) 2 9H 2 O was sonicated in ethanol until uniformly dispersed, and graphyne adsorbing metal salts was obtained by rotary evaporation drying technology; the ultrasonic power was 260W, and the ultrasonic time was 15min.

[0037] (2) NH with a mass ratio of 4:1 to graphyne 2 -H 2 BDC and the product of step (1) were reacted in a reaction kettle at 115°C for 75 h under the condition of dimethylformamide solvent, cooled and washed to obtain a metal organic framework material grown on graphyne in situ;

[0038] (3) Under a nitrogen atmosphere, the temperature was raised to 850 °C at a heating rate of 5 °C / min and kept for 3.5 h, then cooled, and pickled with 2M HCl solution at 85 °C for 26 h to obtain a graphyne in situ growth metal organic framework material .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com