A device for removing iron oxide and improving the detection rate of surface problems and its operation process

A technology of iron oxide and detection rate, which is applied in the direction of workpiece cleaning device, workpiece surface treatment equipment, manufacturing tools, etc., can solve the problems of ultra-thin strip iron oxide falling off and undetectable, achieve small transformation, improve detection rate, The effect of accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

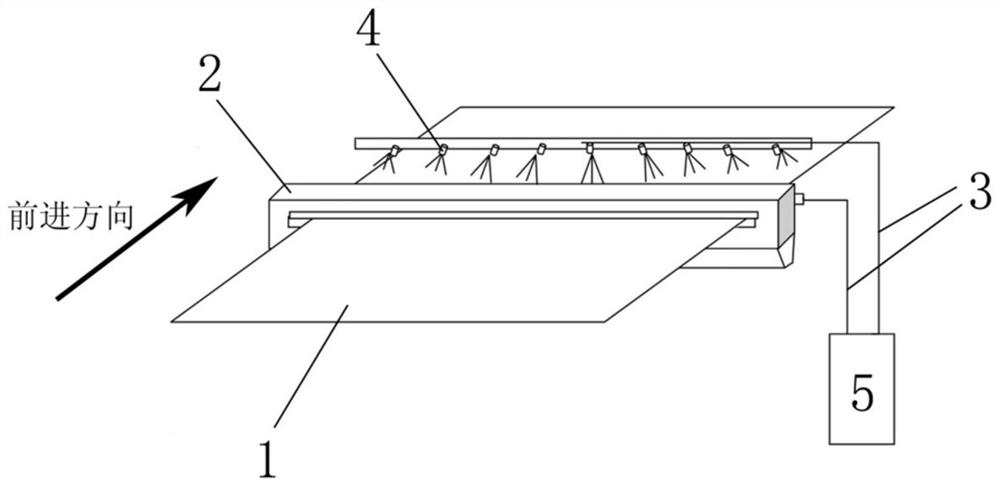

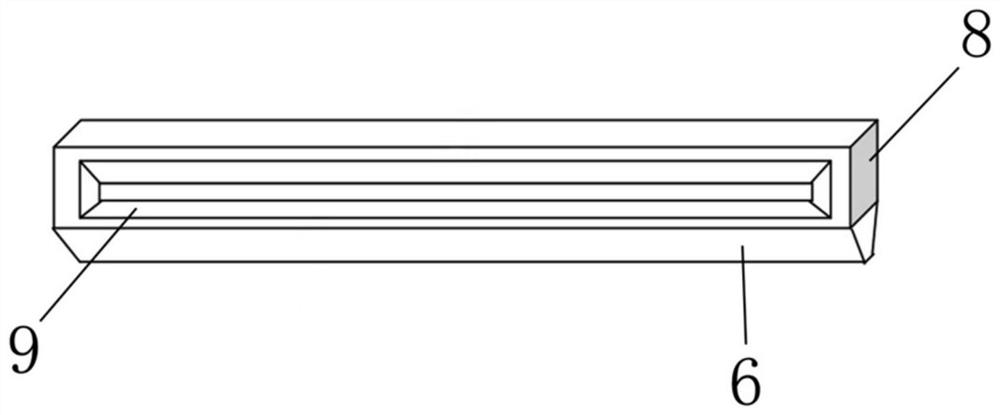

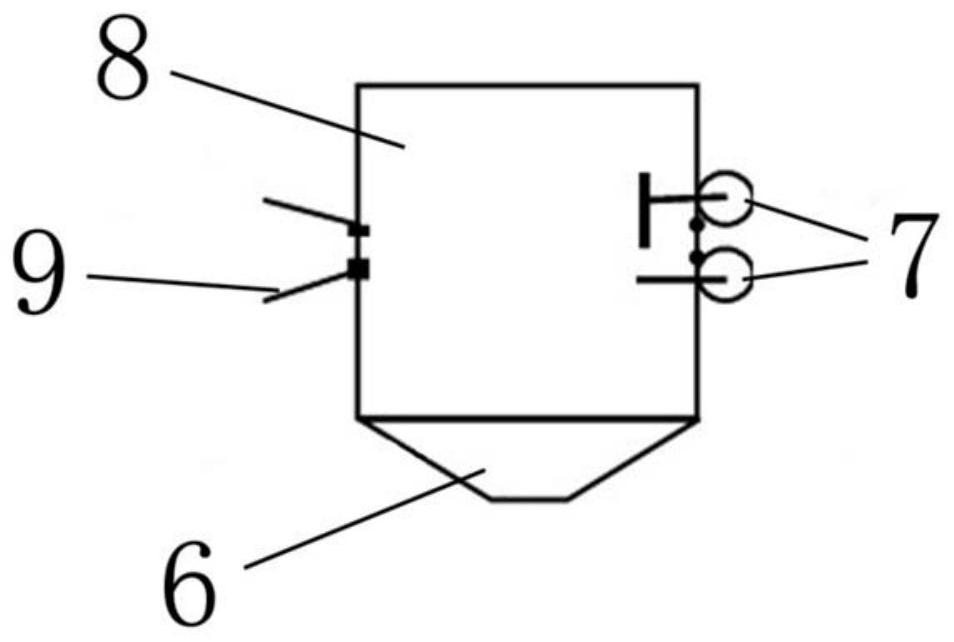

[0021] A device for removing iron oxide and improving the detection rate of surface problems, including ultra-thin strip casting and rolling process lines, such as figure 1 As shown, it also includes an iron oxide powder collection device 2, a compressed air pipeline 3, a high-pressure nozzle 4, an air compression pump 5 and a steel strip 1 to be cleaned. The line moves forward and passes through the iron oxide powder collecting device 2; the compressed air pipeline 3 is arranged above and below the outlet of the iron oxide powder collecting device 2, and the compressed air pipeline 3 is connected with the air compression pump 5; the The high-pressure nozzle 4 is arranged on the compressed air pipeline 3, and the nozzle of the high-pressure nozzle 4 is at 30° to the surface of the steel strip 1 to be cleaned.

[0022] In this embodiment, the number of the high-pressure nozzles 4 is 18, which are divided into groups of 9 and arranged above and below the steel strip 1 to be clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com