Resin II injection method and device for reducing valve jamming

A technology of injection device and valve, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, casting molds, etc., can solve the problems of valve stuck, prevent hardening, reduce the risk of stuck, shorten the The effect of hourglass time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

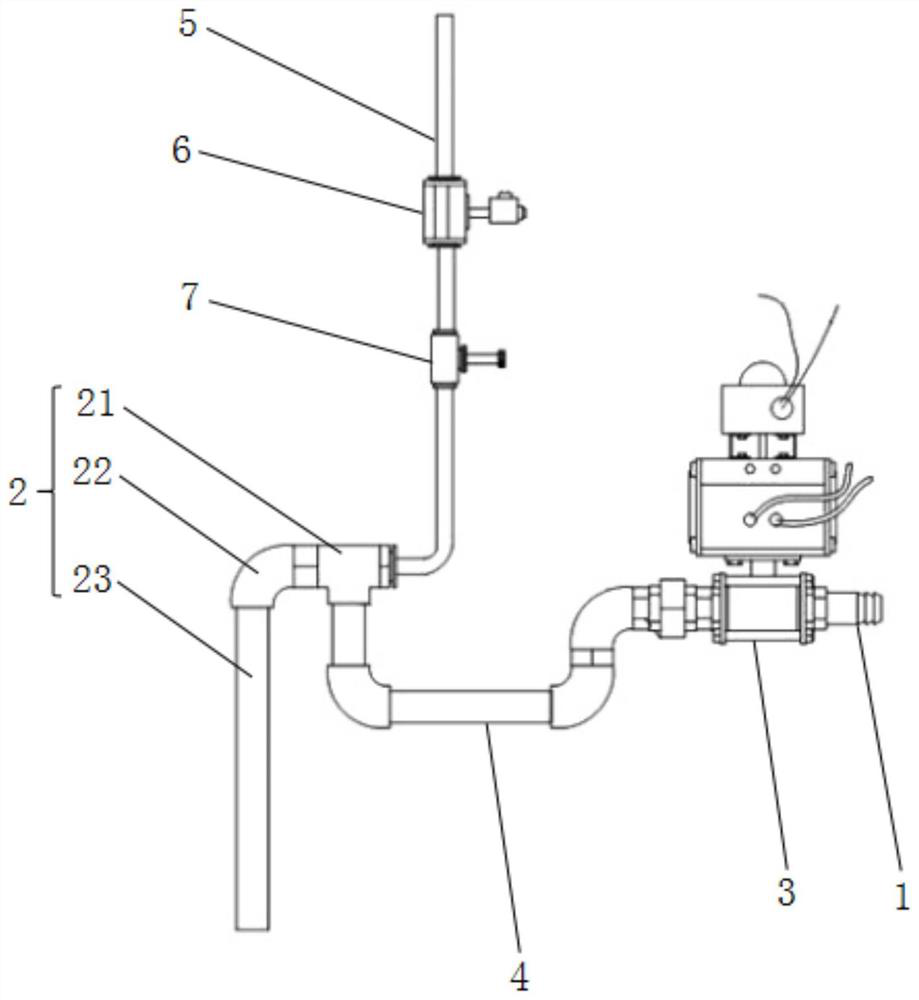

[0019] The present invention relates to a resin II injection method for reducing valve jamming. The method is to inject the resin II out of the valve into the injection pipeline connected with the roller sand machine after passing through a curved pipeline. Among them, the valve is a pneumatic ball valve. By bending the resin II in the pipe to immerse the valve, it is avoided that the resin II adhering to the valve meets the moisture in the air, effectively reducing the risk of the valve being stuck. A blowing device is installed at the end of the curved pipe. After the resin II is injected, the injection pipe is blown to reduce the resin II attached to the injection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com