Torque-limiting automatic wrench for aero-engine assembly

A technology of aero-engine and automatic wrench, which is applied in the direction of motor tools, hand-held tools, manufacturing tools, etc. It can solve the problems of large bolt assembly stress, non-one-time tightening, mounting angle, etc., so as to prevent excessive assembly stress and improve Improvement of work efficiency and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

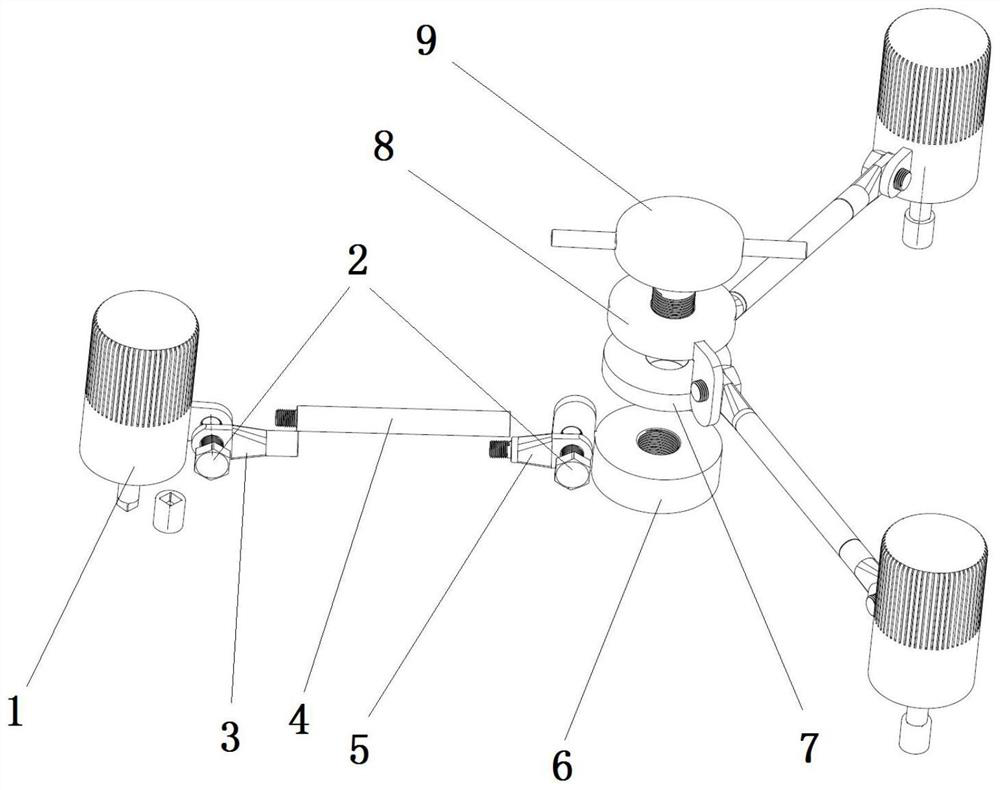

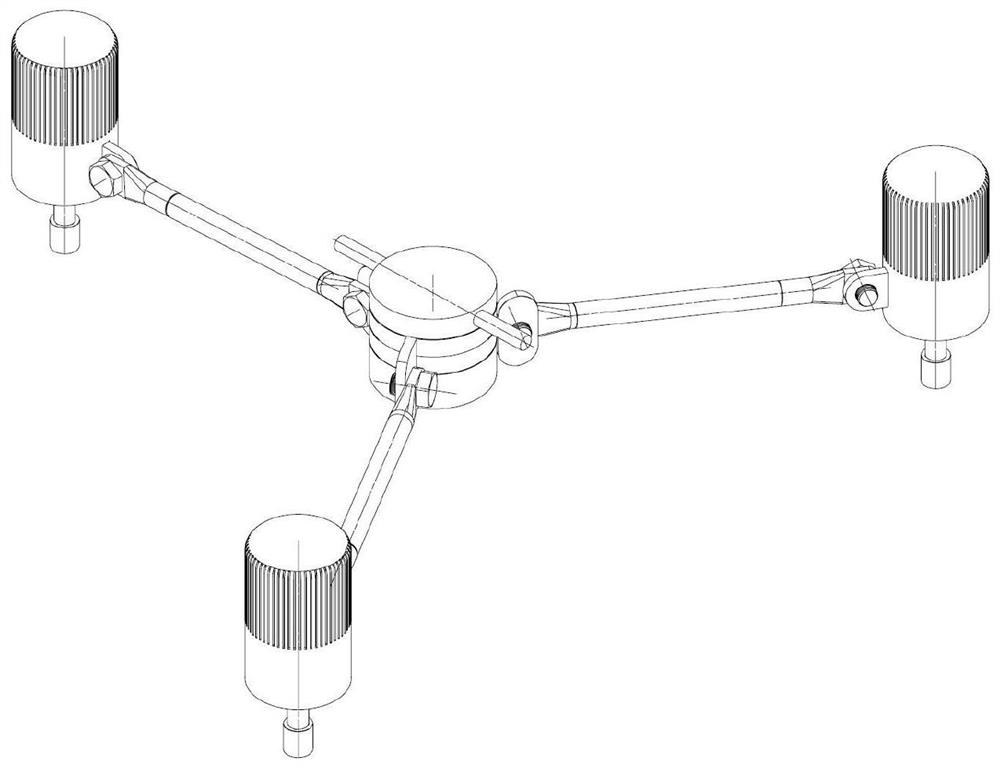

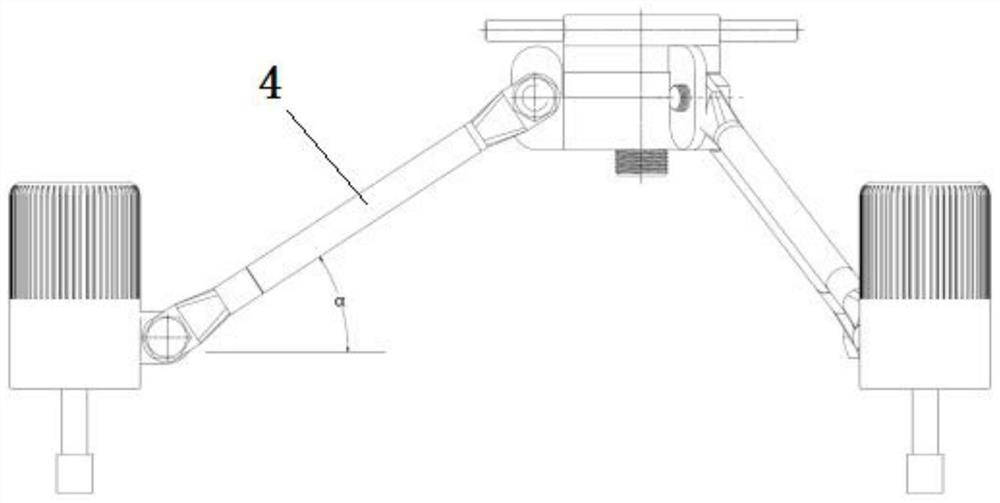

[0023] Such as Figure 1-3 As shown, a torque-limiting automatic wrench for aero-engine assembly according to the present invention includes an electric torque-limiting wrench 1, a lower connector 3, a connecting rod 4, an upper connector 5, a lower ring 6, a middle ring 7, an upper ring 8 and handle nut 9,

[0024] There are three electric torque-limiting wrenches 1, and each electric torque-limiting wrench 1 corresponds to a lower connector 3 connected thereto, and the electric torque-limiting wrench 1 and the lower connector 3 can rotate relatively;

[0025] The three lower connectors 3 are respectively connected to an upper connector 5 through a connecting rod 4;

[0026] The three upper connectors 5 are respectively connected to the sides of the lower ring 6, middle ring 7 and upper ring 8, and can rotate relative to the cor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap