Bamboo spoon milling forming machining assembly

A forming and milling technology, applied in forming/shaping machines, wood processing appliances, sugarcane machining, etc., can solve problems such as affecting the quality of delivery, adverse effects of milling cutters, affecting milling quality, etc., to improve milling quality and simple structure. The effect of compactness and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

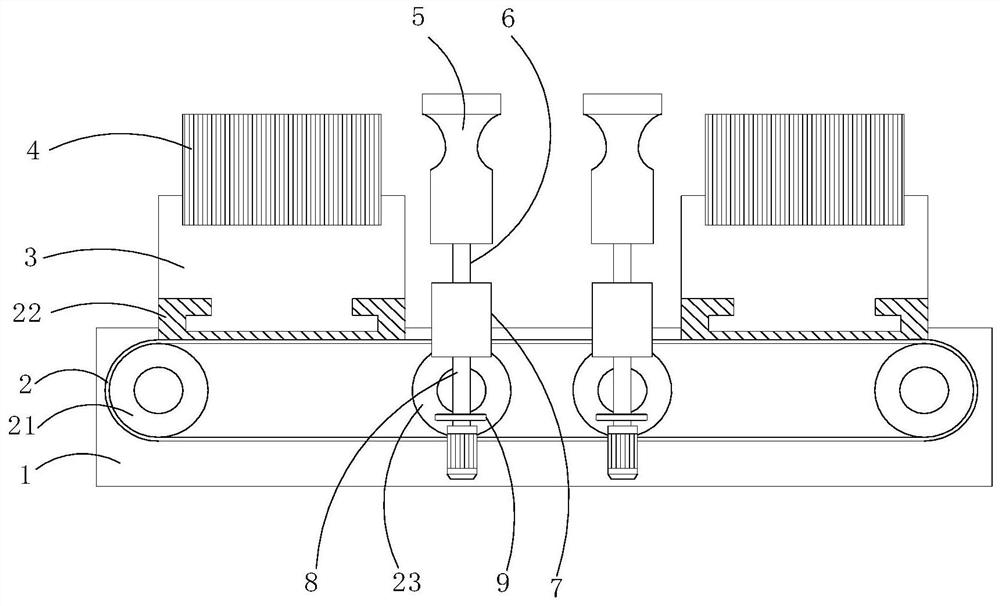

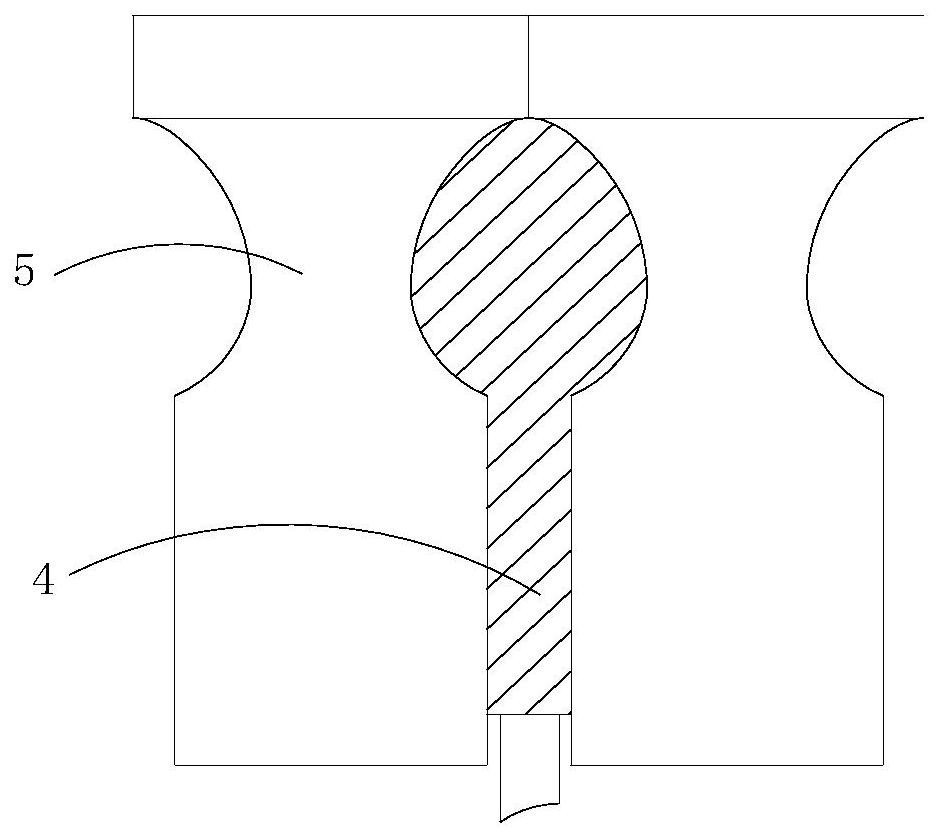

[0027] refer to figure 1 , a bamboo spoon milling forming processing assembly, comprising a frame 1, a conveyor belt 2 for conveying bamboo chips 4, and a milling post 5 for milling bamboo chips 4, two of the milling posts 5 are arranged in groups, and the conveyor belt 2 is located between two Between the milling columns 5, refer to figure 2 , the shape between the two milling columns 5 corresponds to the shape of the target spoon. Two groups of milling columns 5 are set in this assembly, the first group of milling columns 5 is used for shaping the bamboo chips 4 , and the second group of milling columns 5 is used for grinding the bamboo chips 4 .

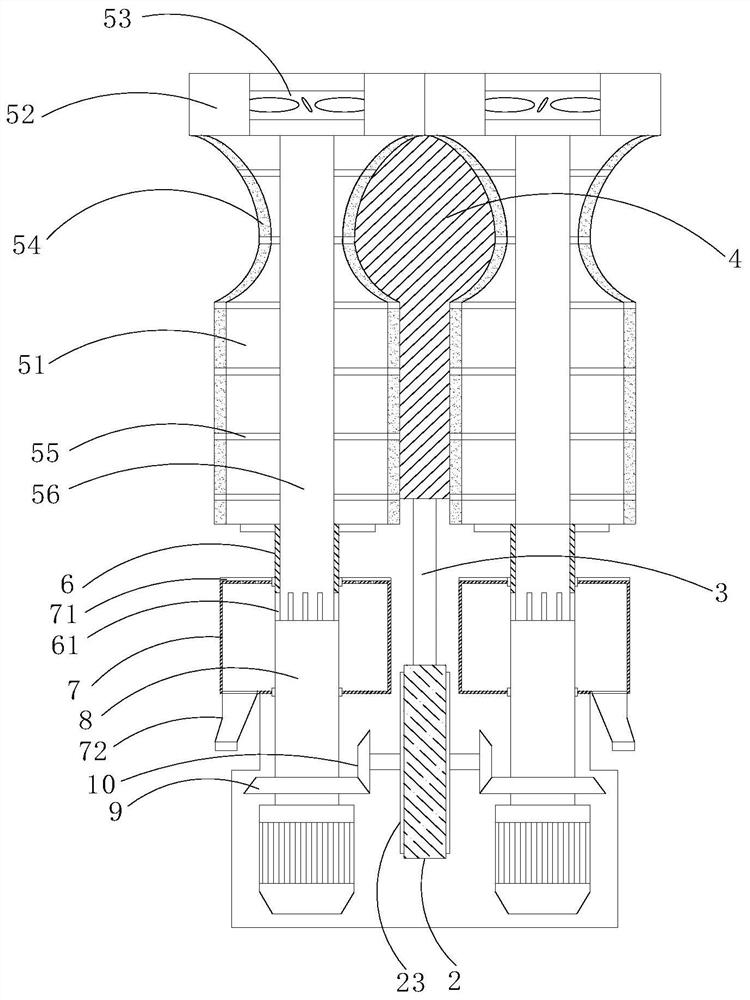

[0028] Further, refer to image 3 , the milling column 5 includes a rotating column 51 and a milling sleeve 54 for milling, the milling sleeve 54 is wrapped around the outside of the rotating column 51, and a milling blade is arranged on the milling sleeve 54 for milling through the milling column 5 Between the bamboo slices. ...

Embodiment 2

[0038] Different from Example 1, refer to Figure 5 with Image 6 , the bottom of the connecting shaft 8 in the bamboo spoon milling and forming processing assembly in this embodiment is provided with a power wheel 11, and the inside of the frame 1 is provided with a transmission belt 12 corresponding to the power wheel 11, and the transmission belt 12 is provided with at least one plectrum 121.

[0039] Further, the conveyor belt 2 is provided with a transmission wheel 21 and a driving wheel 23, and the driving wheel 23 is connected with the dial wheel 13 through a synchronous shaft 14, refer to Figure 7 , the outside of the dial 13 is provided with evenly spaced dial teeth 131 , and dial grooves 132 for accommodating the dial 121 are arranged between the dial teeth 131 . Here, the power wheel 11 can drive the transmission belt 12 to drive, so that the dial 121 promotes the dial 13 to rotate, and the driving wheel 23 follows the dial 13 to rotate, forming the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com