High-toughness PETG material and application thereof

A technology with high toughness and raw materials, applied in the field of PETG, can solve problems such as high melt viscosity, reduced material transparency, and improved material water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

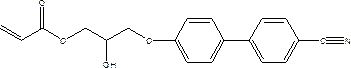

Method used

Image

Examples

Embodiment 1

[0047] Add 70g of polymerized monomer (1), 120g of polymerized monomer (3), 200g of polymerized monomer (5), and 2g of di-tert-butyl peroxide into 400g of toluene, and drop them into the reactor at a constant speed of 110°C. The dropwise addition time is 7 hours. After the dropwise addition is completed, the mixture is kept warm for 2 hours and discharged, and the toughened polymer is obtained after the solvent is removed by rotary evaporation.

[0048] Use gel permeation chromatography to test its molecular weight, Mw=123998.

[0049] 100 parts of PETG material (the molar ratio of ethylene glycol and 1,4 cyclohexanedimethanol is 5:5), 2 parts of the above toughening polymer, 0.2 parts of antioxidant 1010, 0.4 parts of lubricant Honeywell Add polyethylene wax 400A into the high-speed mixer, and stir at 600rpm for at least 20 minutes until it is evenly stirred. The materials are fed into a twin-screw extruder, and the extrusion temperature is 230° C. to obtain masterbatches. ...

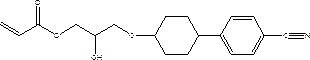

Embodiment 2

[0051] Add 110g of polymerized monomer (2), 300g of polymerized monomer (5), and 1.5g of di-tert-butyl peroxide into 400g of toluene, and drop them into the reactor at a constant speed of 110°C for 7 hours. After the dropwise addition was completed, the mixture was kept warm for 2 hours and discharged, and the toughened polymer was obtained after the solvent was removed by rotary evaporation.

[0052] Use gel permeation chromatography to test its molecular weight, Mw=157662.

[0053] 100 parts of PETG material with a weight average molecular weight of about 250,000 (the molar ratio of ethylene glycol and 1,4 cyclohexanedimethanol is 5:5), 3 parts of the above toughened polymer, 0.3 parts of antioxidant 626, Add 0.4 parts of lubricant pentaerythritol stearate into a high-speed mixer, and stir at 600 rpm for at least 20 minutes until uniform. The materials are fed into a twin-screw extruder, and the extrusion temperature is 230° C. to obtain masterbatches.

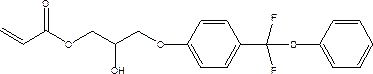

Embodiment 3

[0055] Add 150g of polymerized monomer (1), 100g of polymerized monomer (2), 150g of polymerized monomer (4) and 1.7g of di-tert-butyl peroxide into 400g of toluene, and drop them into the reactor at a constant speed of 110°C. The dropwise addition time is 7 hours. After the dropwise addition is completed, the mixture is kept warm for 2 hours and discharged, and the toughened polymer is obtained after the solvent is removed by rotary evaporation.

[0056] Use gel permeation chromatography to test its molecular weight, Mw=137792.

[0057] 100 parts of PETG material with a weight average molecular weight of about 250,000 (the molar ratio of ethylene glycol and 1,4 cyclohexanedimethanol is 5:5), 5 parts of the above toughened polymer, 0.3 parts of antioxidant 1029, Add 0.5 part of lubricant magnesium stearate into the high-speed mixer, and stir at 600 rpm for at least 20 minutes until the mixture is uniform. The materials are fed into a twin-screw extruder, and the extrusion tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com