Casting mold facilitating demoulding casting production

A technology for die castings and castings, which is applied in the field of casting molds for the production of easy-to-die castings, can solve the problems of slow cooling speed, time-consuming and labor-intensive, manual picking, etc., so as to ensure the safety of life and property, ensure personal safety, and avoid accidental touch. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

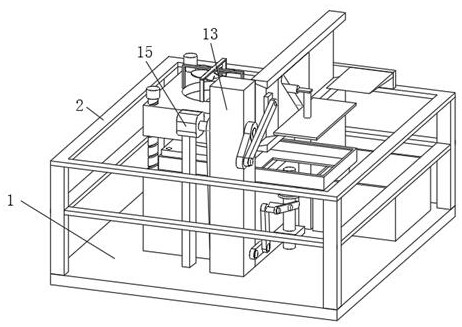

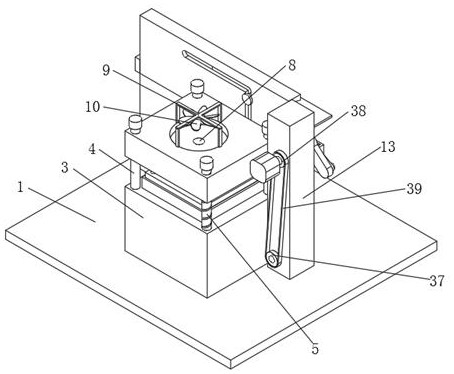

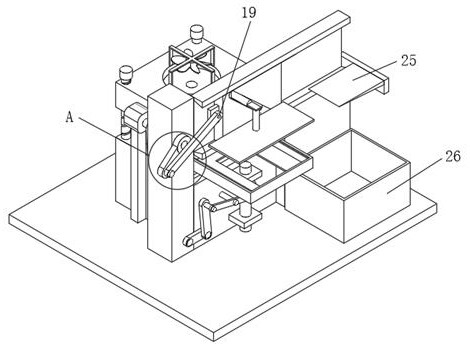

[0040] Example: Reference Figure 1-8 The casting mold shown is convenient for casting production, including a base 1, a fixed platform 3 is fixedly installed on the top of the base 1, a plurality of limit rods 4 are fixedly installed on the top of the fixed platform 3, and the top of the fixed platform 3 rotates A lead screw 5 is installed, a plurality of limit rods 4 and the lead screw 5 are movably socketed and installed with the same mold mechanism, the top of the fixed table 3 is fixed with a movable mechanism, the top of the base 1 is fixed with a pillar, and the top of the pillar A servo motor 15 is fixedly installed, the model of the servo motor 15 is 80st-m02430, the output end of the servo motor 15 is driven and installed with a drive shaft 14, the top of the base 1 is fixedly installed with a support column 13, and the side of the support column 13 is provided with a rotating hole And the movable hole, one end of the driving shaft 14 passes through the rotating hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com