Gas atomization metal powder collecting device

A collection device and metal powder technology, applied in the field of gas atomization metal powder collection device, can solve the problems of incoherent preparation process, poor cooling effect, poor powder quality, etc., to improve production efficiency and powder quality, and facilitate powder collection , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

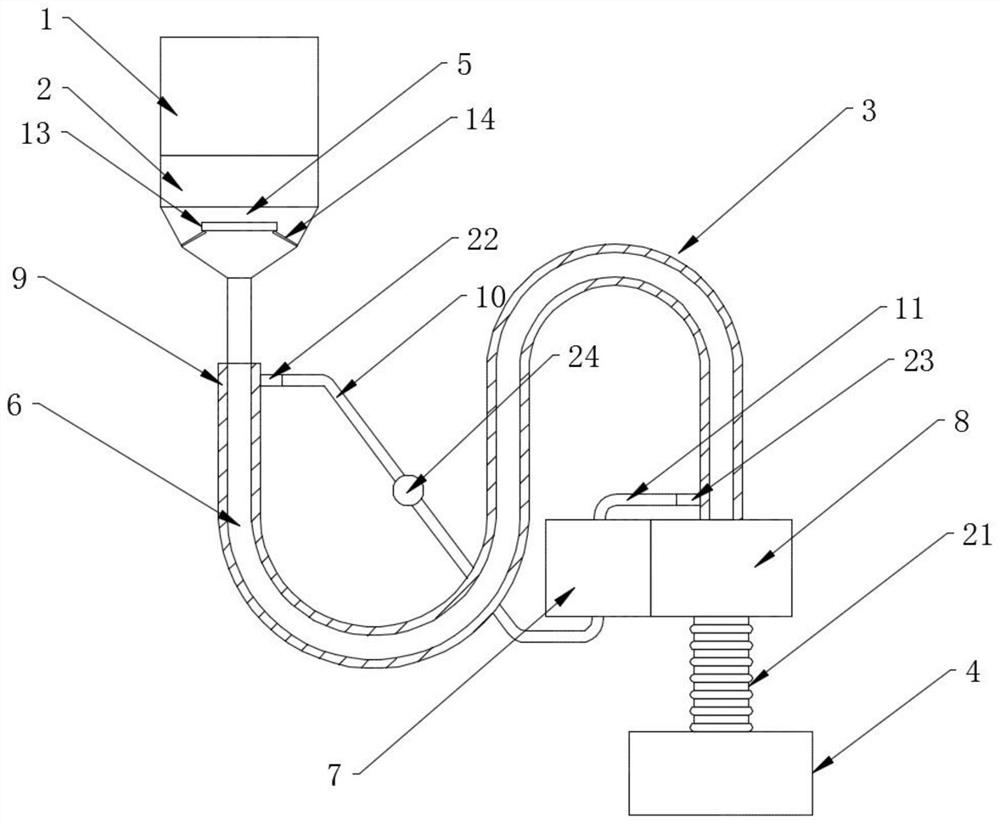

[0043] combined with Figure 1-3 , a gas atomized metal powder collection device, including a crucible 1, an atomization chamber 2, a powder collection device 3 and a screening device 4, directly connects the atomized metal powder to the screening device, during the powder transfer process Cool it down to ensure the continuity of the overall process and improve production efficiency;

[0044] The crucible 1 is used for molten metal,

[0045] The atomization chamber 2 is arranged at the bottom of the crucible 1, and is used to atomize the molten metal into powder,

[0046] The powder collection device 3 is arranged between the atomization chamber 2 and the screening device 4, and is used for collecting and conveying the metal powder and cooling it,

[0047] The sieving device 4 is used to sieve the metal powder,

[0048] The powder collection device 3 includes a primary air-cooled chamber 5, a powder delivery pipe 6, a water-cooled circulation system 7 and a secondary air-co...

Embodiment 2

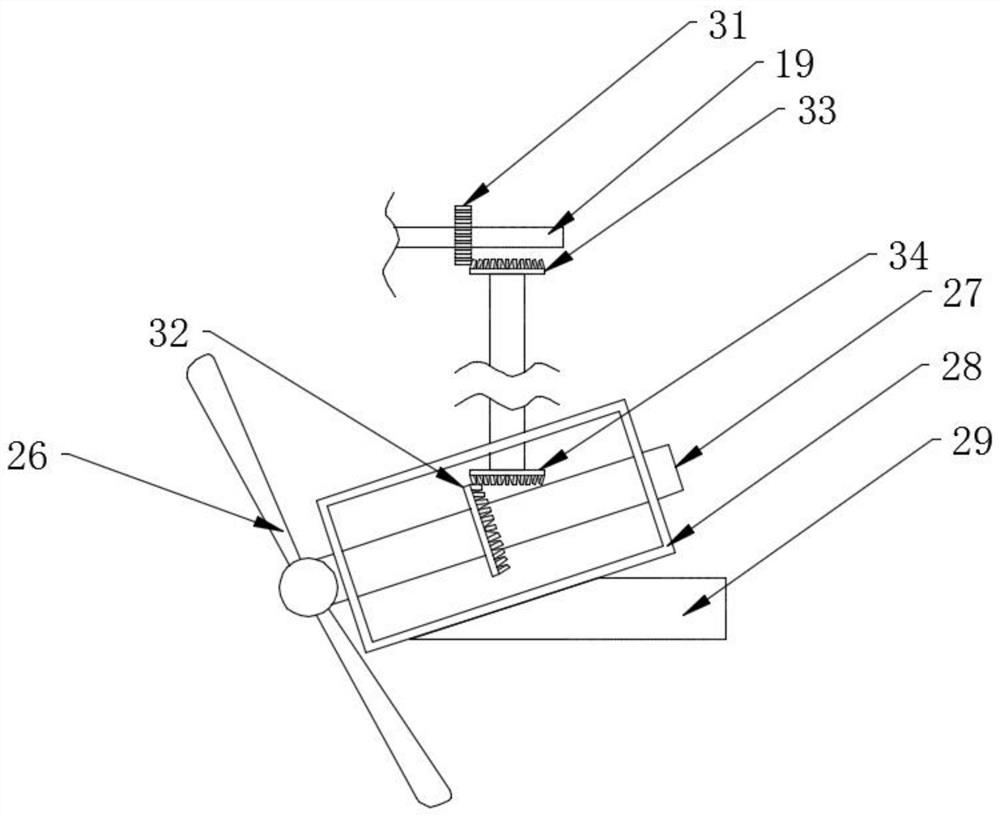

[0070] combine Figure 4 , the inner wall of the hose 21 is provided with an airgel protective layer 25. In the actual use of the first embodiment, since the hose 21 is used to connect the screening device 4, the temperature of individual metal powders may be too high, which will affect For the service life of the hose 21, after adding the airgel protective layer 25, it can effectively insulate the heat, and the airgel has a good deformation effect, which can produce a certain deformation along with the hose, avoiding the impact of the hose due to the excellent material Normal use.

Embodiment 3

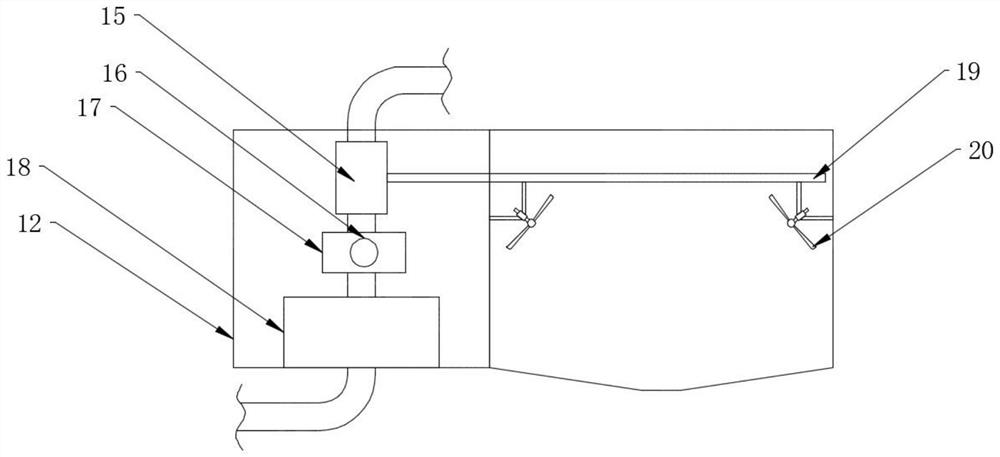

[0072] combined with figure 2 , the bottom of the secondary air-cooling chamber 8 is an inclined structure, which can facilitate the rolling and sliding of metal powder along the inner wall to avoid powder accumulation, and at the same time cooperate with the cooling fan to better collect the powder and enter the screening device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com