Waste paper bulk packaging system based on vertical bulk packaging machine

A baler machine, vertical technology, applied in the field of papermaking equipment, can solve the problem of low baler efficiency, achieve the effect of optimized structure, simple structure, not easy to jam or disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

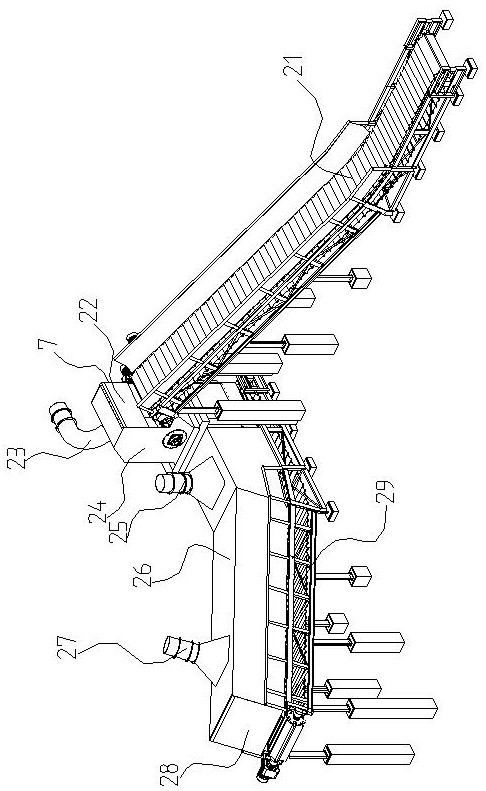

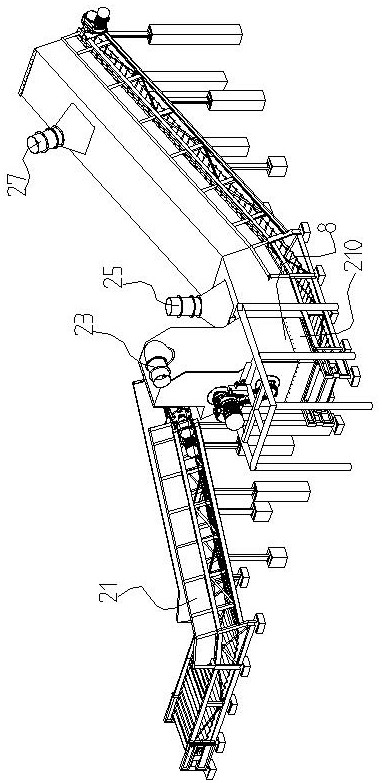

[0058] like Figure 1 to Figure 16 As shown, this embodiment discloses a waste paper unpacking system based on a vertical unpacking machine, including a vertical unpacking machine 24, and the vertical unpacking machine 24 includes a housing 1 and a paper dispensing roller arranged in the housing.

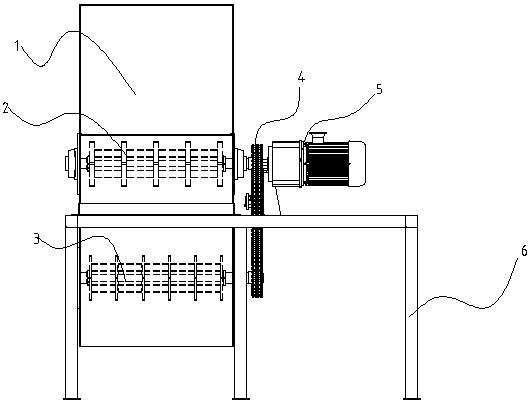

[0059] like Figure 3 to Figure 10 As shown, the structure and principle of the specific vertical unpacking machine are as follows: the unpacking roll includes an upper unpacking roll 2 and a lower unpacking roll 3 which are arranged in parallel up and down inside the housing 1, and the upper unpacking roll 2 and the lower unpacking roll 3 are connected by a transmission chain 4, and are driven by a geared motor 5 to realize co-rotation. The upper loose paper roller 2 and the lower loose paper roller 3 are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com