Aluminum coil cleaning agent and production method thereof

A production method and cleaning agent technology are applied in the field of cleaning agents to achieve the effects of improving cleaning ability, reducing energy consumption and achieving good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

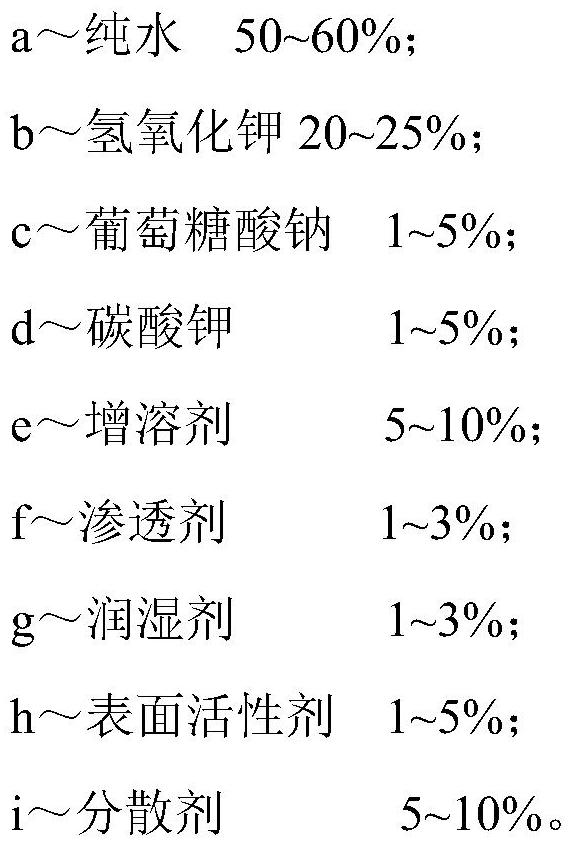

[0079] The following percentage components of the aluminum coil cleaning agent described in this example:

[0080]

[0081]

[0082] The production method of described aluminum coil cleaning agent is as follows:

[0083] (1) Add a into the reaction kettle, start the mixer, adjust the speed from slow to fast, and control the speed at 200-300 rpm;

[0084] (2) Add b under stirring, wait until b is completely dissolved, and continue stirring for 3 to 5 minutes after the solution is clear and transparent visually;

[0085] (3) Add c under stirring state, until c is completely dissolved, and after the solution is clear and transparent visually, continue stirring for 3 to 5 minutes;

[0086] (4) Add d under stirring state, wait until d is completely dissolved, and after the solution is clear and transparent visually, continue stirring until the temperature drops below 40°C;

[0087] (5) Add e to the cylinder, start the stirring paddle, adjust the speed from slow to fast, and...

Embodiment 2

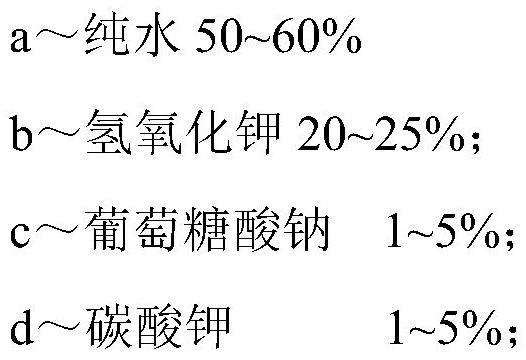

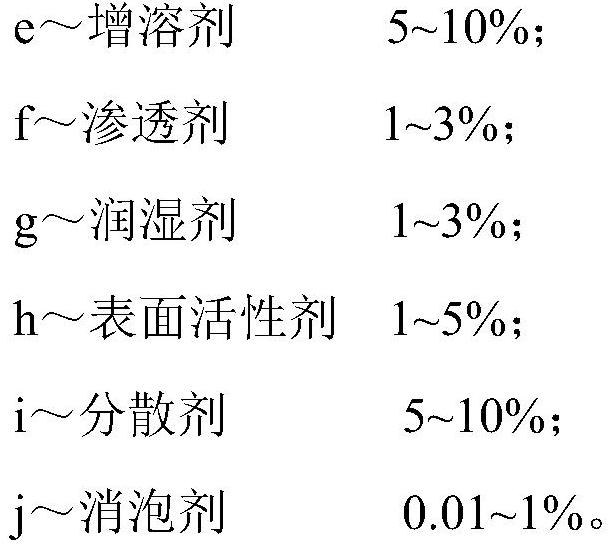

[0095] The following percentage components of the aluminum coil cleaning agent described in this example:

[0096]

[0097]

[0098] The production method of described aluminum coil cleaning agent is as follows:

[0099] (1) Add a into the reaction kettle, start the mixer, adjust the speed from slow to fast, and control the speed at 200-300 rpm;

[0100] (2) Add b under stirring, wait until b is completely dissolved, and continue stirring for 3 to 5 minutes after the solution is clear and transparent visually;

[0101] (3) Add c under stirring state, until c is completely dissolved, and after the solution is clear and transparent visually, continue stirring for 3 to 5 minutes;

[0102] (4) Add d under stirring state, wait until d is completely dissolved, and after the solution is clear and transparent visually, continue stirring until the temperature drops below 40°C;

[0103] (5) Add e to the cylinder, start the stirring paddle, adjust the speed from slow to fast, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com