Cross-layer column quality defect repairing and reinforcing method for frame-core tube

A technology with quality defects and core tubes, applied in building maintenance, construction, building types, etc., can solve problems such as adverse effects of column bearing functions, hidden safety hazards, etc., to achieve high application and promotion value, easy to grasp, and ensure the effect of repair quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

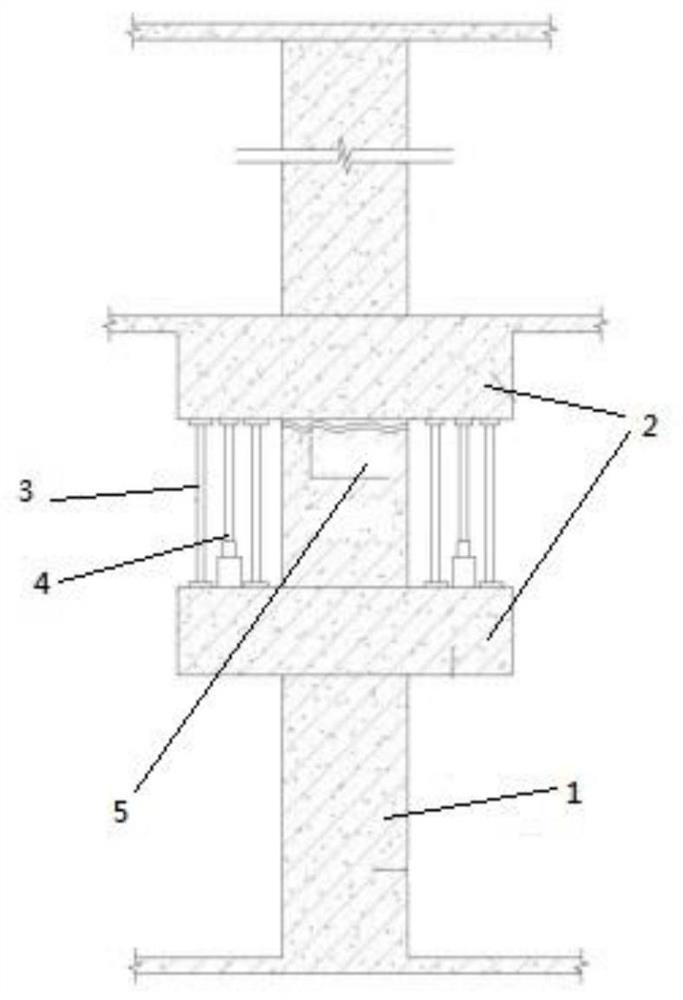

[0025] (1) Build the support system: before removing the loose concrete, a pre-top ring beam with a height of 800mm and a side length of 2200mm should be built at the upper and lower ends of the damaged column. The support of the roof and the steel pipe pier is a predictive passive preventive measure for the small displacement that may be caused by the local unloading of the chiseled replacement concrete. The upper end of the lower ring beam and the lower end of the upper ring beam are both padded with 20x400x400 steel plates. Steel wedge plugged tightly;

[0026] (2) Removal of damaged concrete: There are weak slag layers and deep holes in the damaged column. The loose concrete of the damaged column between the upper and lower ring beams shall be thoroughly chiseled and cleaned by hand tapping and finely beating. The demolition height shall be 250-350mm from the upper and lower edges of the defective part, that is, the total height shall be 500-700mm (adjustable according to ...

Embodiment 2

[0031] (1) Build the support system: before removing the loose concrete, a pre-top ring beam with a height of 800mm and a side length of 2200mm should be built at the upper and lower ends of the damaged column. The support of the roof and the steel pipe pier is a predictive passive preventive measure for the small displacement that may be caused by the local unloading of the chiseled replacement concrete. The upper end of the lower ring beam and the lower end of the upper ring beam are both padded with 20x400x400 steel plates. Steel wedge plugged tightly;

[0032] (2) Removal of damaged concrete: There are shallow holes in the damaged column. Thoroughly chisel and clean the loose shallow defect area of the damaged column between the upper and lower ring beams by manual tapping. The demolition height is about 50mm from the upper and lower edges of the shallow defect area (until reaching the dense concrete), and the chiseling cannot be done. If there is a large vibration to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com