Method for testing damp-heat aging performance of coated fabric

A coating fabric, damp heat aging technology, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problems of high risk, poor operability, high cost, etc., and achieve high degree of simulation, The effect of strong designability and strong data reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of material bulk samples

[0031] Prepare according to the test requirements of different characteristic values, and the specific sample preparation is as follows:

[0032] a) Fracture strength test piece

[0033] Make samples with a length of 350 mm and a width of 50 mm according to the warp or weft direction.

[0034] b) Interlayer adhesion test sample

[0035] Make the sample into a sample with a length of 200mm and a width of 50mm. Separate the coated surface from the base fabric at one end of the sample. For the sample that cannot be separated, stretch it on a tensile testing machine until it breaks, and then remove the sample. Then peel off.

[0036] 2) Preparation of seam samples

[0037] a) Heat seal peel strength test sample

[0038] The sealing strips with a length of 100mm are bonded to the coated fabric in a hot air-tight manner. The bonding method can be arranged in parallel and the distance between adjacent sealing strips is 50mm, or co...

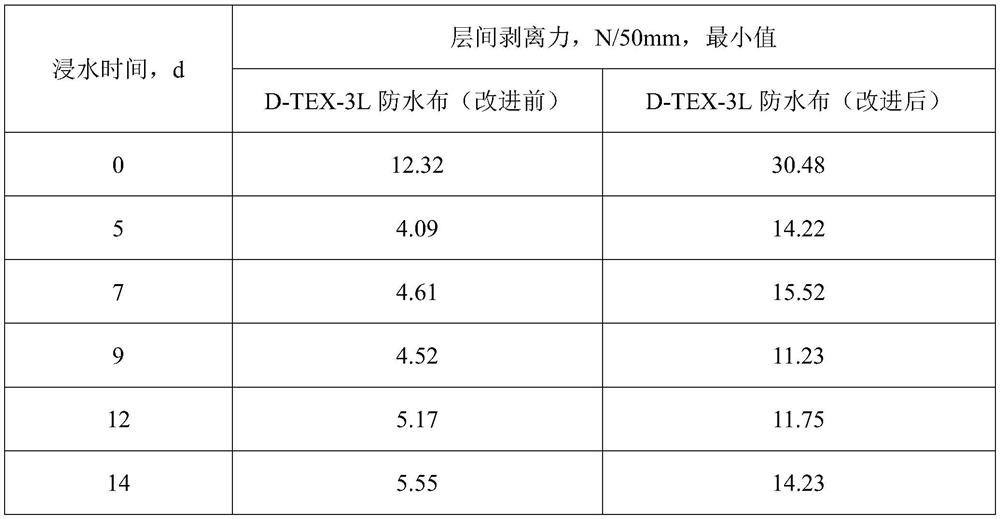

Embodiment 1

[0053] Provide a method for testing the moisture-heat aging performance of waterproof and moisture-permeable cloth, which includes firstly preparing a standard sample, soaking it in hot water at 80°C, and then taking it out according to the predetermined soaking time to test the interlayer peeling force of the sample. The rate of change in the degree of decline in the peeling force between layers of the moisture-permeable fabric is used to evaluate the hot water aging resistance of the waterproof and moisture-permeable fabric.

[0054] The waterproof and moisture-permeable fabric is used as the main material of the surface of the pilot's sea life-saving clothing. Before the service life is reached, there are frequent faults such as layering and water leakage of the waterproof fabric, which needs to be improved urgently. In 2019, the hot water aging test and evaluation of the waterproof and moisture-permeable fabrics before and after the improvement were passed, and the effect w...

Embodiment 2

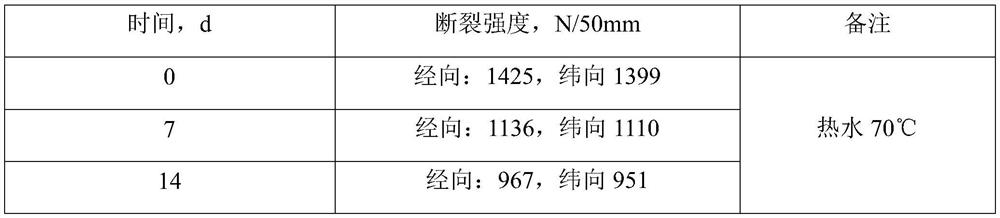

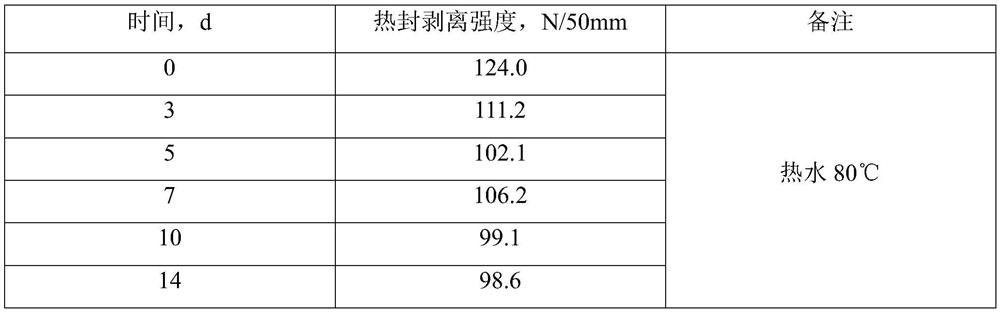

[0058] Provide a method for testing the damp heat aging performance of polyurethane tape, including firstly preparing a standard sample, soaking it in hot water, and then taking it out according to the predetermined soaking time to test the breaking strength, heat-sealing peel strength, and heat-sealing seam peel strength The hot water aging resistance of polyurethane tape is evaluated by judging the rate of change of the breaking strength of polyurethane tape, heat-sealing peel strength, and heat-sealing peel strength. The specific test results are shown in Table 2-4.

[0059] Table 2 Polyurethane tape breaking strength test results

[0060]

[0061] Table 3 Test results of heat-sealing peel strength of polyurethane tape

[0062]

[0063] Table 4 Test results of peel strength of heat-sealing joints of polyurethane adhesive tape

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com