Composition with acne removing repair effects, skin care preparation and preparation method of skin care preparation

A technology of composition and efficacy, applied in the field of personal care products, can solve the problems of inhibiting Propionibacterium acnes by a single mechanism and the effect is difficult to show, achieve easy scale and standardized promotion, convenient and feasible preparation method, improve tolerance and The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

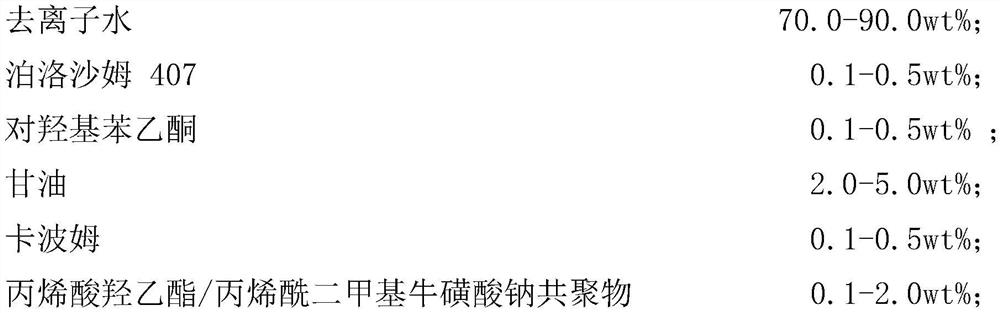

[0033] Raw materials and ratio:

[0034] A component:

[0035]

[0036] B component:

[0037]

[0038] C component comprises at least following weight percent raw material:

[0039]

[0040] Preparation:

[0041] (1) Weigh the A component material in advance, soak the carbose in the emulsification preparation pot until it is completely wetted, then put in the A component material in turn, homogeneously disperse evenly, start stirring and heating, after heating to 80-85°C, Keep warm and stir for 10 minutes;

[0042] (2) Weigh the material of component B in advance, put it into the oil pan, start stirring and heating, after heating to 70-80°C, pump it into the emulsification preparation pot, keep it warm at 70-75°C, and homogenize at high speed for 10 minutes;

[0043] (3) After cooling down to 45°C, put in component C materials, homogenize at a slow speed for 3-6 minutes, preferably 5 minutes at a slow speed, stir (40 rpm) for 15-25 minutes, preferably 20 minutes, ...

Embodiment 2

[0045] Raw materials and ratio:

[0046] A component:

[0047]

[0048] B component:

[0049]

[0050] C component comprises at least following weight percent raw material:

[0051]

[0052]

[0053] Preparation:

[0054] (1) Weigh the A component material in advance, soak the carbose in the emulsification preparation pot until it is completely wetted, then put in the A component material in turn, homogeneously disperse evenly, start stirring and heating, after heating to 80-85°C, Keep warm and stir for 10 minutes;

[0055] (2) Weigh the material of component B in advance, put it into the oil pan, start stirring and heating, after heating to 70-80°C, pump it into the emulsification preparation pot, keep it warm at 70-75°C, and homogenize at high speed for 10 minutes;

[0056] (3) After cooling down to 45°C, pre-moisten the chitin with pentylene glycol until it is uniform, then put in the C component material, homogenize at a slow speed for 3-6 minutes, preferab...

Embodiment 3

[0058] Raw materials and ratio:

[0059] A component:

[0060]

[0061] B component:

[0062]

[0063] C component comprises at least following weight percent raw material:

[0064]

[0065]

[0066] Preparation:

[0067] (1) Weigh the A component material in advance, soak the carbose in the emulsification preparation pot until it is completely wetted, then put in the A component material in turn, homogeneously disperse evenly, start stirring and heating, after heating to 80-85°C, Keep warm and stir for 10 minutes;

[0068] (2) Weigh the material of component B in advance, put it into the oil pan, start stirring and heating, after heating to 70-80°C, pump it into the emulsification preparation pot, keep it warm at 70-75°C, and homogenize at high speed for 10 minutes;

[0069](3) After cooling down to 45°C, pre-moisten the chitin with pentylene glycol until it is uniform, then put in the C component material, homogenize at a slow speed for 3-6 minutes, preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com