Quick-acting hemostatic sponge and preparation method thereof

A hemostatic sponge and quick-acting technology, which is applied in the field of quick-acting hemostatic sponge and its preparation, can solve the problems of uneven polysaccharide conjugates and unsatisfactory hemostatic effect, and achieve the effects of improving hemostatic effect, accelerating wound healing, and uniform group distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

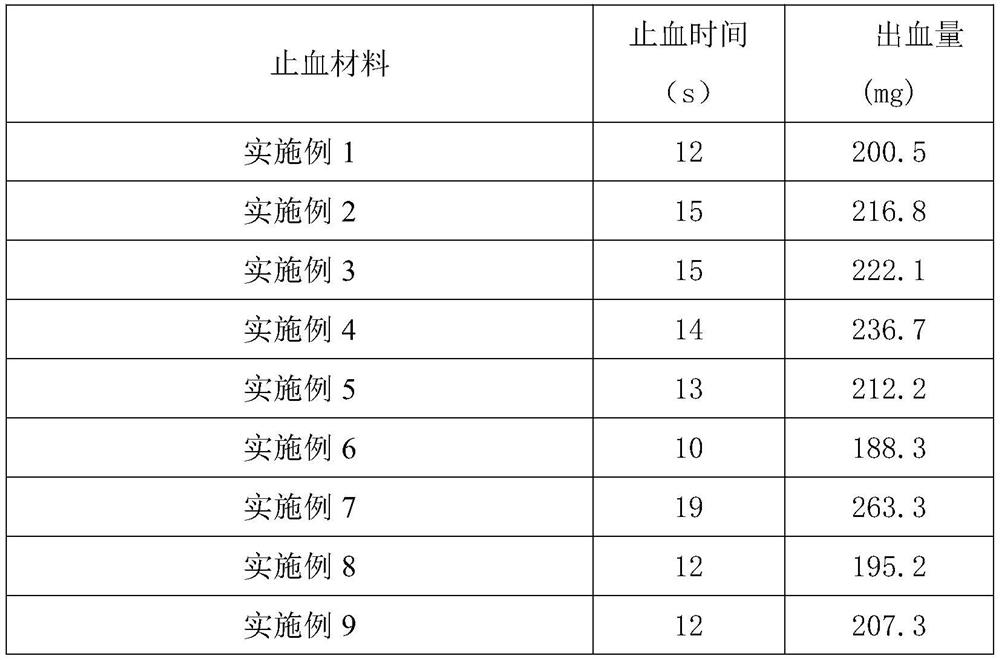

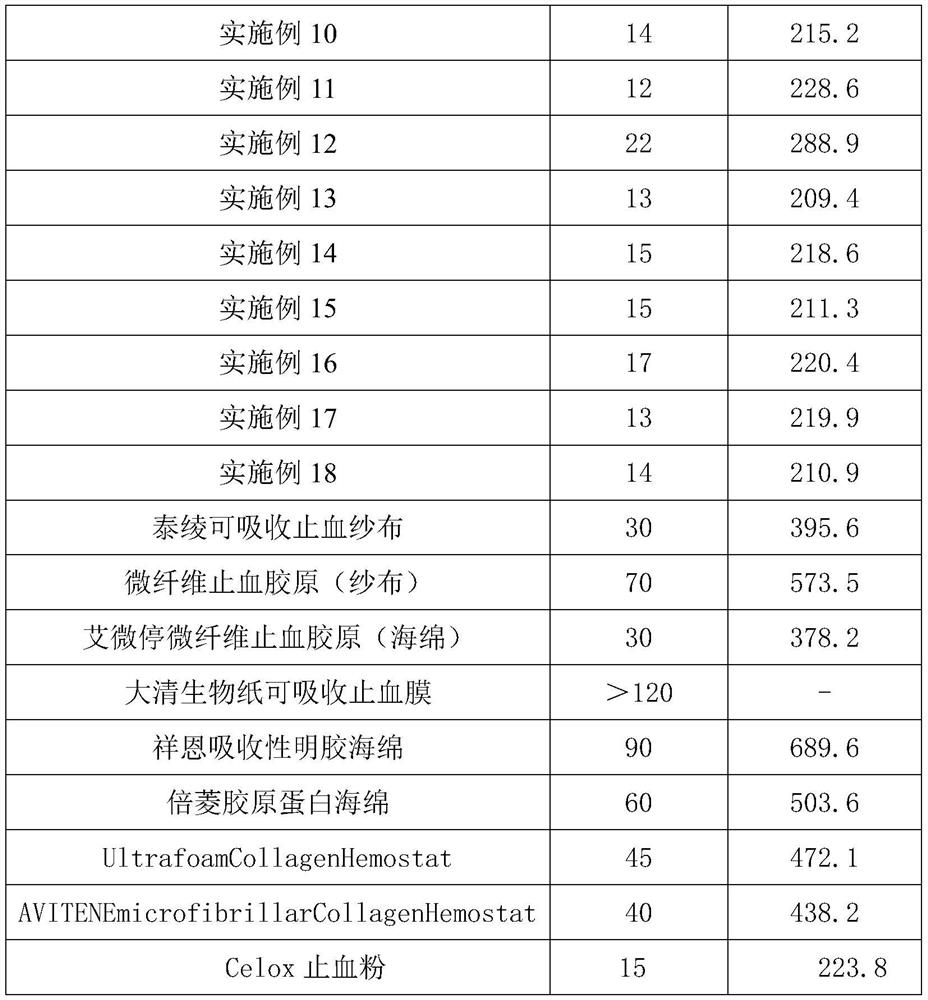

Examples

Embodiment 1

[0034] In this embodiment, the quick-acting hemostatic sponge comprises gelatin, a polysaccharide conjugate and a cross-linking agent, and the polysaccharide conjugate is a hydrophilic and hydrophobic co-grafted polysaccharide conjugate.

[0035] Wherein, gelatin:polysaccharide conjugate:crosslinking agent=300:100:1.

[0036] The steps of the polysaccharide conjugate in the above-mentioned quick-acting hemostatic sponge are:

[0037] 2 g of chitosan was dissolved in 100 mL of 0.2M acetic acid, and 100 mL of ethanol was added, followed by 364 uL of octanoic anhydride, and 2.38 g of EDC and 1.43 g of NHS. The reaction was overnight, and 3 mL of 5M sodium hydroxide was added to adjust the pH to 10, filtered, washed with water and ethanol for 5 times, and dried in a vacuum oven to obtain hydrophobically modified chitosan;

[0038] 2g of hydrophobically modified chitosan was dissolved in 100mL of 0.2M acetic acid, nitrogen was purged for 10 minutes, the pH was adjusted to 5.0, and...

Embodiment 2

[0045] This example is the same as Example 1 except for the co-grafted chitosan conjugate with hydrophobicity and hydrophobicity. The steps for preparing the polysaccharide conjugate are as follows:

[0046] 2 g of chitosan was dissolved in 100 mL of 0.2M acetic acid, and 100 mL of ethanol was added, heated to 45°C, followed by 0.2 g of dodecanoic anhydride, and 2.38 g of EDC and 1.43 g of NHS. The reaction was overnight, and 3 mL of 5M sodium hydroxide was added to adjust the pH to 10, filtered, washed with water and ethanol for 5 times, and dried in a vacuum oven to obtain hydrophobically modified chitosan;

[0047] 2g of hydrophobically modified chitosan was dissolved in 100mL of 0.2M acetic acid, nitrogen was purged for 10 minutes, the pH was adjusted to 5.0, and then 1.19g of 3,4-dihydroxyphenylpropionic acid, 2.38g of EDC and 1.43 g of NHS were reacted overnight, dialyzed against acidified deionized water for 3 days, and lyophilized to obtain a hydrophilic and hydrophobic ...

Embodiment 3

[0049] In this example, gelatin: polysaccharide conjugate: cross-linking agent = 500:100:1; in addition, the hydrophilic and hydrophobic co-grafted chitosan conjugate is different from Example 1, and the steps for preparing the polysaccharide conjugate are:

[0050] 2 g of chitosan was dissolved in 100 mL of 0.2M acetic acid, and 100 mL of ethanol was added, heated to 65°C, followed by 0.154 g of dodecanoic anhydride, and 2.38 g of EDC and 1.43 g of NHS. The reaction was overnight, and 3 mL of 5M sodium hydroxide was added to adjust the pH to 10, filtered, washed with water and ethanol for 5 times, and dried in a vacuum oven to obtain hydrophobically modified chitosan;

[0051] 2g of hydrophobically modified chitosan was dissolved in 100mL of 0.2M acetic acid, nitrogen was purged for 10 minutes, the pH was adjusted to 5.0, and then 1.19g of 3,4-dihydroxyphenylpropionic acid, 2.38g of EDC and 1.43 g of NHS were reacted overnight, dialyzed against acidified deionized water for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com