Preparation method of denitrified fly ash externally doped with denitration by-product

A technology for fly ash and by-products, which is applied in the field of preparation of denitrified fly ash, can solve the problems of decreased concrete strength, abnormal ammonia smell, and pH value of ammonia smell from fly ash volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

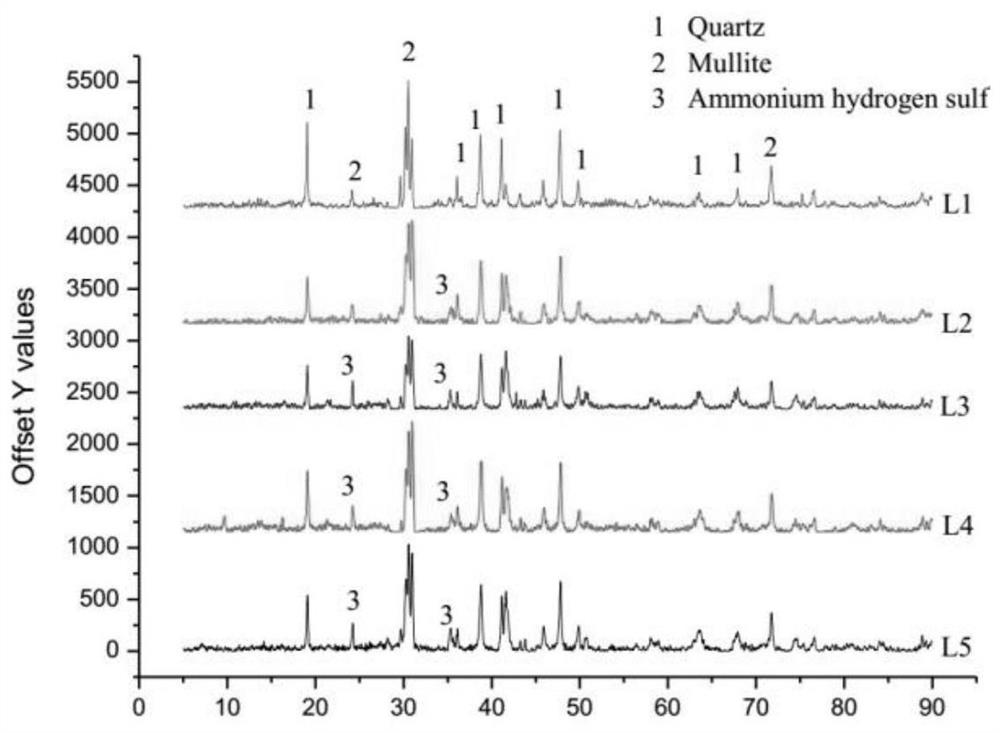

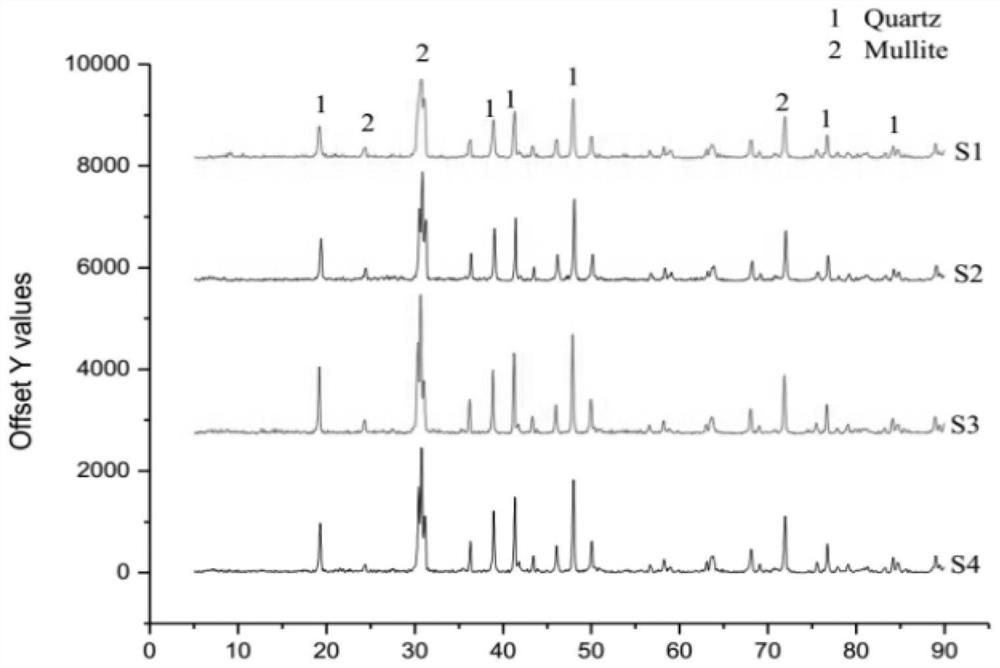

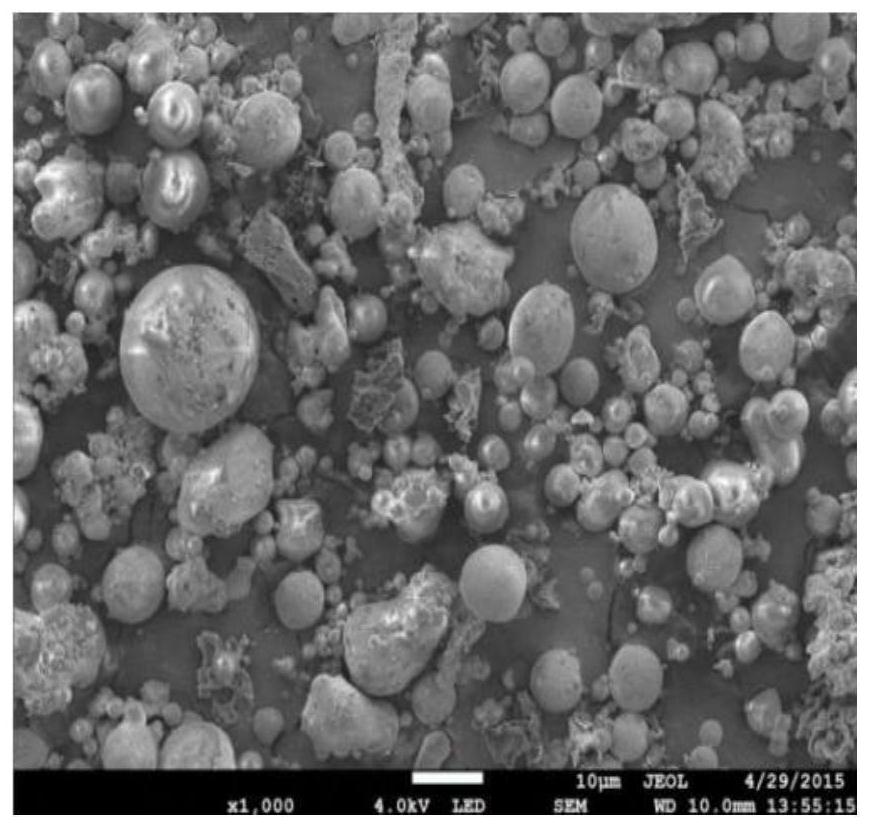

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that this specific embodiment is not intended to limit the scope of rights of the present invention.

[0031] The preparation method of denitrification fly ash externally mixed with denitrification by-products provided in this specific embodiment comprises the following steps:

[0032] Step 1, after pulverizing ammonium bisulfate or ammonium sulfate crystal particles through a mill, put them into a sealed bag and seal them;

[0033] Step 2, put the fly ash and the denitrification by-product powder in the weight ratio of 8:1 in the step 1 together into the mixer and stir evenly to obtain the mixed powder;

[0034] Step 3, evenly spread the mixed powder in step 2 into the heating container, cover and seal it, then put it into a constant temperature box with a temperature of 150-175°C and heat for 3-5 hours;

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com