Technique for smelting ultra-pure TiNi shape memory alloy

A technology of memory alloy and alloy, which is applied in the field of material metallurgy, can solve the problems of generalization, difficulty in obtaining high-performance memory alloy, and insufficient consideration of the special process of Ni and Ti.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

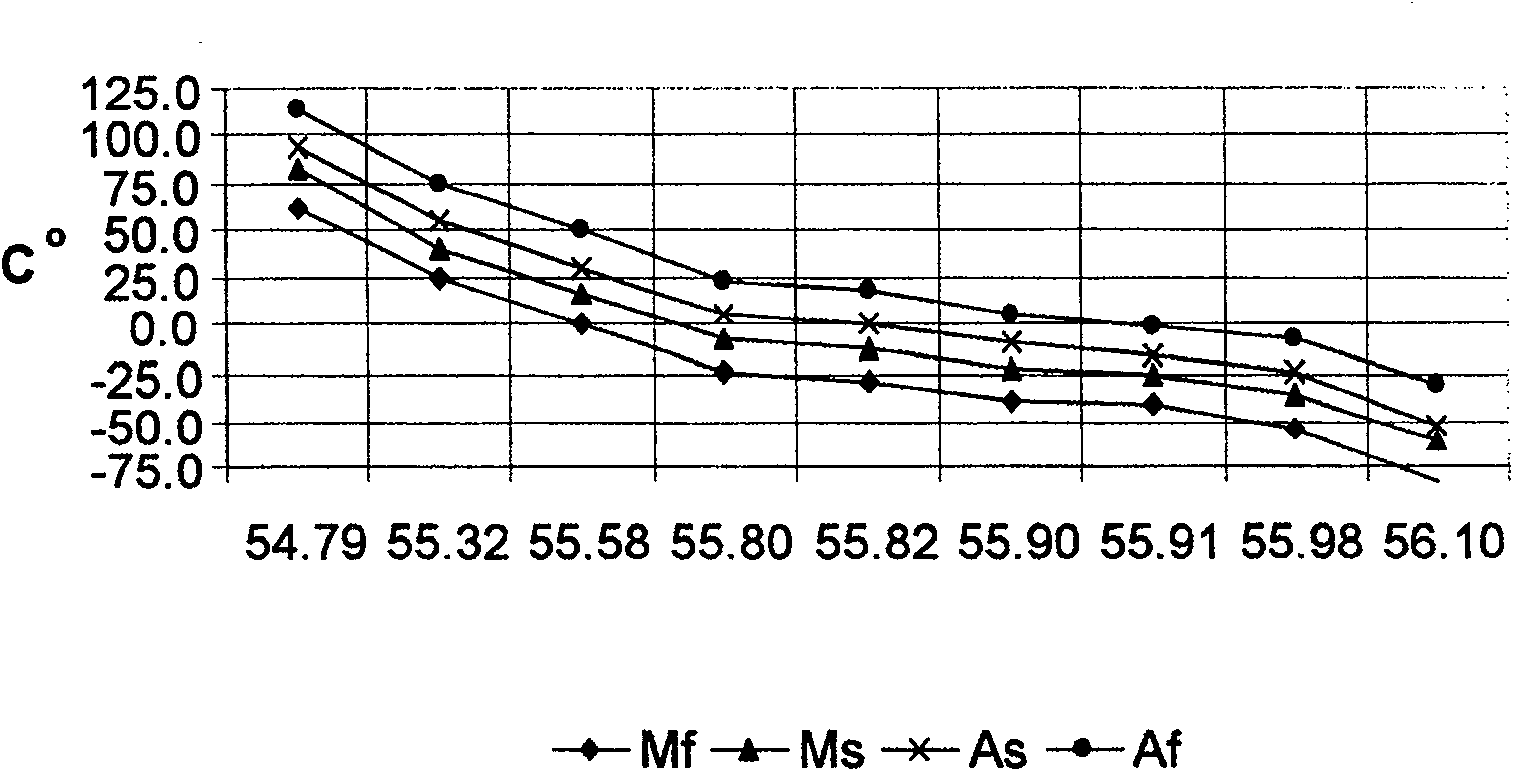

Image

Examples

Embodiment 1

[0046] TiNi shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0047] 1. Raw material charging, according to the designed composition ratio Ti49.15Ni50.85 atomic ratio to take raw materials, No. 0 Ti and No. 1 Ni, the order of charging is that Ni and 40% Ti are loaded into the crucible at the same time, and the remaining 60% Ti Put it in the hopper for later use.

[0048] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0049] 3. The alloy is melted, and the power is sent to 30kw-20kw-0kw, and the heating is reduced to keep the reaction heat balance of the system and stir evenly.

[0050] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0051] 5. Power transmission heating, increase the heating power from 0-20KW, keep the reaction heat balance of the system, and stir.

[0052] 6. Alloy refining, r...

Embodiment 2

[0055] TiNiCr shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0056] 1. Raw material charging, take the raw material according to the designed composition ratio (%) Ti49.15Ni50.85Cr0.3 atomic ratio (the meaning of Cr0.3 is based on the ratio of Ti+Ni=100%at is 0.3%at), 0 No. Ti and No. 1 Ni, the order of charging is that Ni and 40% Ti0.3% Cr are loaded into the crucible at the same time, and the remaining 60% Ti is put into the hopper for standby.

[0057] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0058] 3. The alloy is melted and sent to 30kw1-20kw-0kw, and the heating is reduced to keep the reaction heat balance of the system and stir evenly.

[0059] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0060] 5. Power transmission heating, 0-20KW increments, keep the system reaction heat b...

Embodiment 3

[0064] TiNiV shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0065] 1. Raw material charging, take the raw material according to the designed composition ratio (%) Ti49.15Ni50.85V0.5 atomic ratio (the meaning of V0.5 is based on the ratio of Ti+Ni=100%at is 0.5%at), 0 No. Ti and No. 1 Ni, the charging sequence is that Ni and 40% Ti are loaded into the crucible at the same time, and the remaining 60% Ti is put into the hopper for standby.

[0066] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0067] 3. Alloy melting and power transmission 30kw-20kw-0kw, decreasing heating, stirring evenly.

[0068] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0069] 5. Electric heating, 0-20KW increments, stirring.

[0070] 6. Alloy refining, refining at 1300-1400 degrees for 5 minutes, solidifying the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com