Marine diesel engine waste gas washing water treatment device utilizing ship waste heat

A marine diesel engine and water treatment device technology, applied in the direction of heating water/sewage treatment, gaseous effluent wastewater treatment, gas treatment, etc., can solve a large number of white fog, secondary pollution, washing water environmental hazards, etc., to reduce Effects of white mist, consumption reduction, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

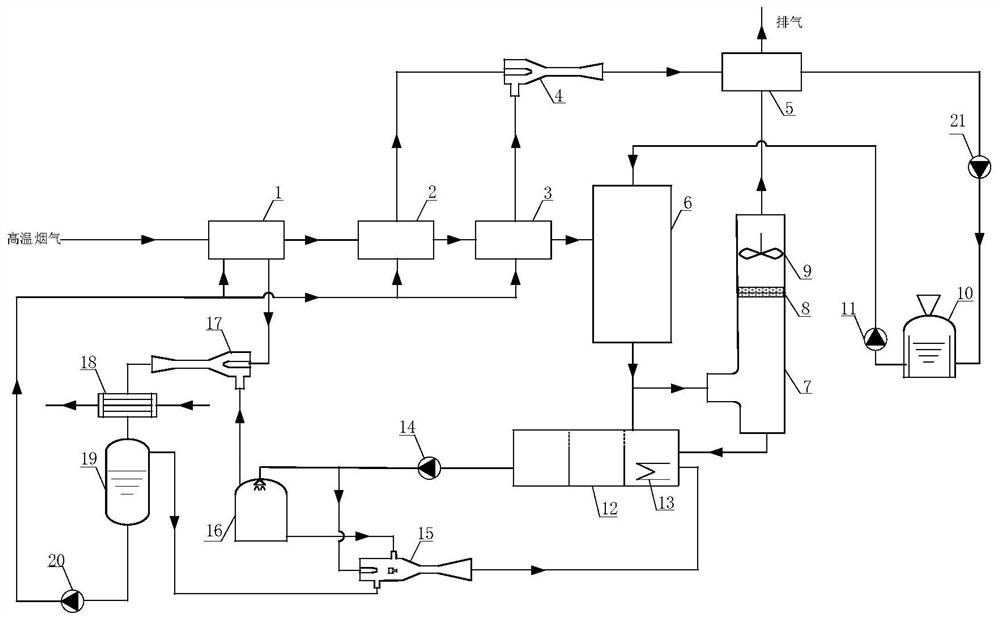

[0028] The present invention will be further elaborated below by means of the accompanying drawings and examples. Such as figure 1 As shown, a marine diesel engine exhaust gas washing water treatment device utilizing ship waste heat, including a flue gas washing module and a wastewater treatment recycling module;

[0029] The flue gas washing module includes a heat exchange unit, a washing tower 6, a dispensing box 10, a metering pump 11, a chimney 7, a liquid-gas separation device 8, a fan 9, a flue gas heat exchanger 5, a two-stage filtration sedimentation cabinet 12, an electric Heater 13 and sewage pump 14;

[0030] The wastewater treatment recycling module includes a steam ejector, an ejector pump 15, a flash tank 16, a condenser 18, a liquid storage tank 19 and a centrifugal pump a20;

[0031] The heat exchange unit includes three heat exchangers, the three heat exchangers are respectively the primary heat exchanger 1, the secondary heat exchanger 2 and the tertiary he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com