Flame-retardant rigid polyurethane thermal insulation material and preparation method thereof

A technology of rigid polyurethane and thermal insulation materials, applied in the field of flame-retardant rigid polyurethane, which can solve the problems of increased thermal conductivity, poor thermal insulation performance, and the flammability of rigid polyurethane foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Some specific examples of the present invention are provided below to help further understanding of the present invention, but the protection scope of the present invention is not limited to these examples.

[0016] A method for preparing a flame-retardant rigid polyurethane thermal insulation material according to the present invention, the steps are as follows:

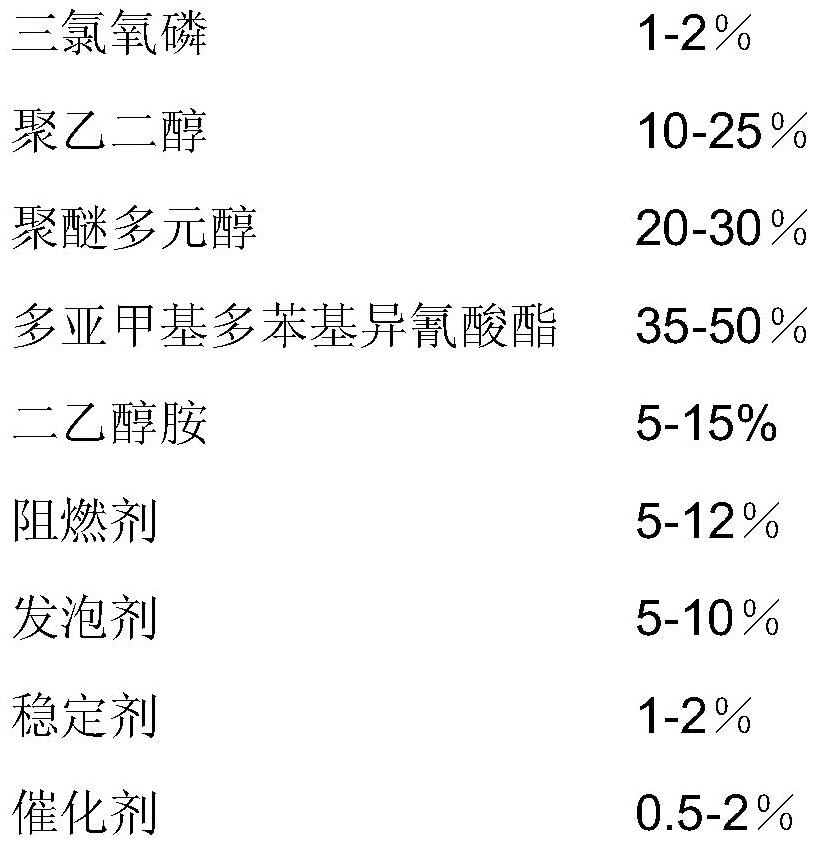

[0017] (1) Take the required phosphorus oxychloride, polyether polyol, polyethylene glycol, catalyst, stabilizer, flame retardant and foaming agent according to the formula ratio, and melt the diethanolamine into a liquid and put it together with these raw materials Put it into a 1000mL plastic beaker, and stir it with a multifunctional electric stirrer at high speed for 10-15 minutes;

[0018] (2) Add the foaming agent required by the formula into the mixture of step (1), stir at high speed for 1-2 minutes, then add polymethylene polyphenylisocyanate, stir at high speed for 8-10 seconds, and mix the resultin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com