Preparation method of golden film

A thin film and golden technology, applied in electrolytic coating, surface reaction electrolytic coating, anodic oxidation, etc., can solve the problems of difficult to achieve ideal golden appearance, reddish color, low surface gloss, etc., and achieve pure color and good antibacterial effect , high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

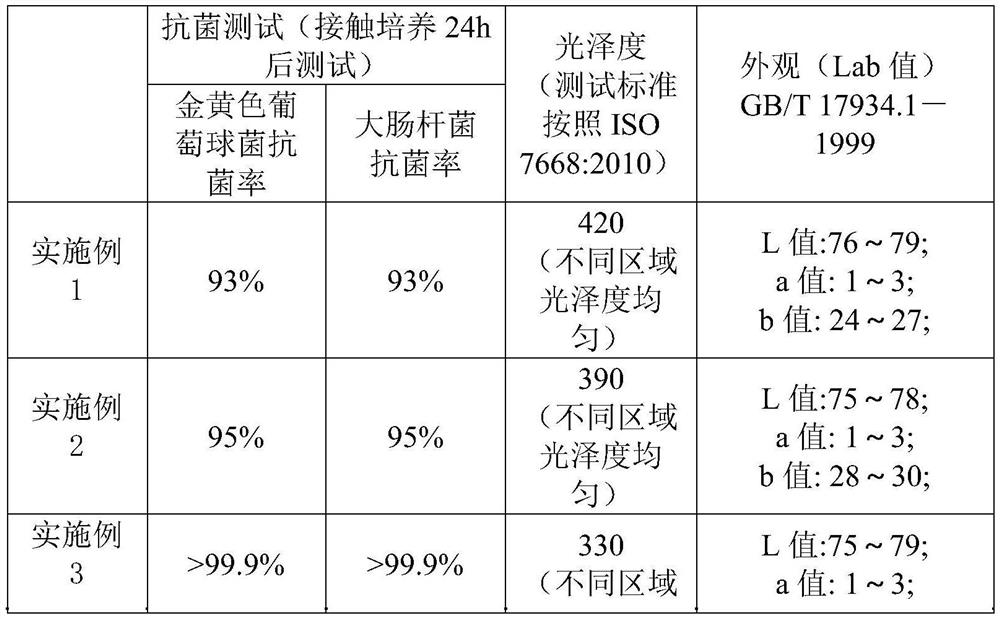

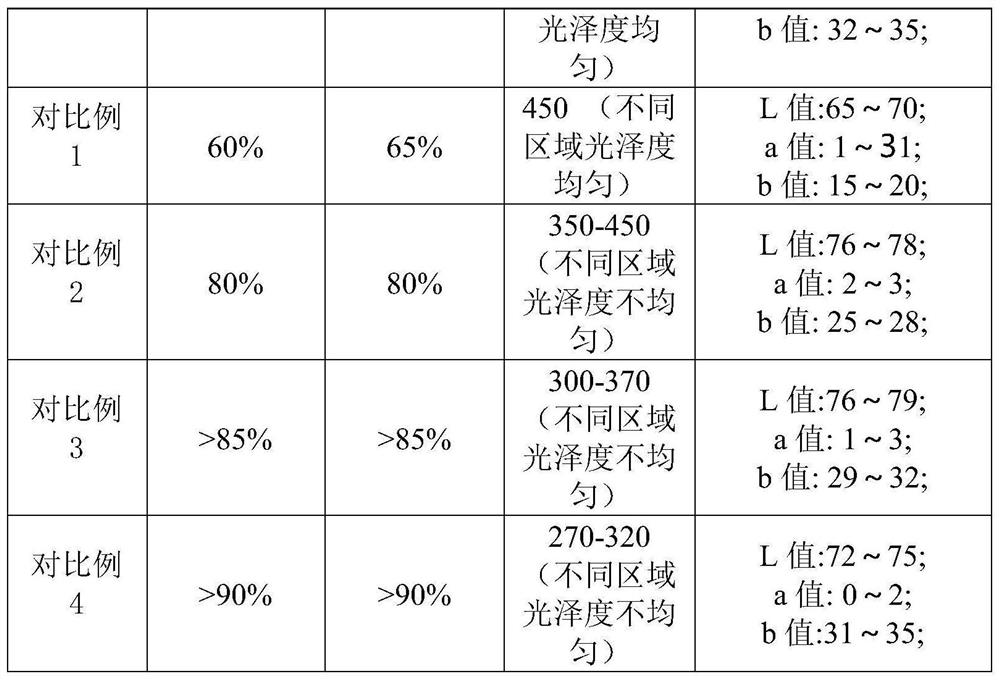

Examples

Embodiment 1

[0025] The preparation method step of the golden thin film of embodiment 1 is:

[0026] 1. Speed gradient mechanical polishing

[0027] ① Perform low-speed mechanical polishing on the surface of the aluminum alloy blank workpiece, the speed is 1000r / min, and the time is 5min;

[0028] ②Then perform medium-speed mechanical polishing on the workpiece after low-speed polishing, the speed is 2000r / min, and the time is 10min;

[0029] ③Finally, perform high-speed mechanical polishing on the workpiece after medium-speed polishing, with a rotation speed of 3000r / min and a time of 15 minutes;

[0030] Through the setting of gradient mechanical polishing, as the rotation speed and polishing time increase, the oxide film naturally formed on the surface of the aluminum alloy substrate will be gradually peeled off, and the roughness of the substrate surface will become smaller and smaller, which can effectively improve the surface gloss of the film .

[0031] 2. Degreasing treatment ...

Embodiment 2

[0051] The preparation method of the golden thin film of Example 2 is basically the same as that of Example 1, the difference is that in the gold dyeing process, the dyeing time is changed, and the dyeing time is 15 minutes.

Embodiment 3

[0053]The preparation method of the golden thin film of Example 3 is basically the same as that of Example 1, the difference is that in the gold dyeing process, the dyeing time is changed, and the dyeing time is 20 minutes.

[0054] The obtained golden thin film is evenly formed, and the copper particles are dispersed and distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com