Preparation method of 1,2-bis(3-methyl phenoxy) ethane

A technology of methylphenoxy and ethane is applied in the field of preparation of 1,2-diethane heat-sensitive sensitizer, which can solve the problems of low yield, hydrolysis of dichloroethane, difficulty in post-processing, etc. High yield, improve conversion rate, avoid the effect of hydrolysis side reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In a specific embodiment, the preparation method of 1,2-bis(3-methylphenoxy)ethane thermal sensitizer of the present invention comprises the following steps: (1) adding m-cresol and Potassium hydroxide, stir and heat up to 130-150°C, completely dissolve, cool down to below 80°C, add dichloroethane; (2) After adding, close the autoclave, replace with nitrogen for 3 times, and pass in a small amount of nitrogen , to make the pressure reach 0.1-0.2Mpa, raise the temperature to 130-150°C, and keep the heat for 15-20 hours; (3) cool down to 70-80°C, add water, heat up to 80-100°C and stir for 1-2 hours, then cool down to Precipitate at room temperature for more than 3 hours, filter, wash with water, and dry to obtain a white product. in,

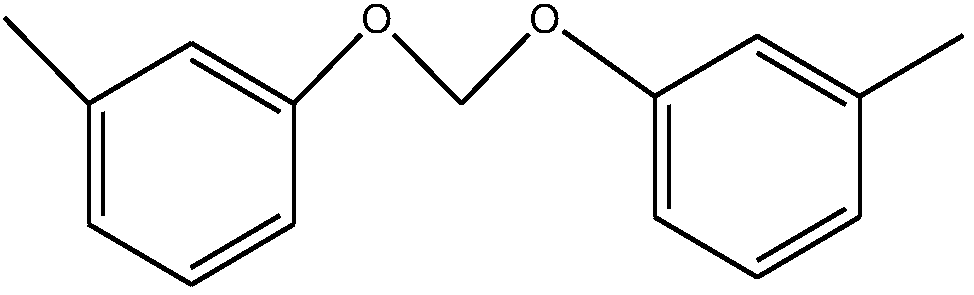

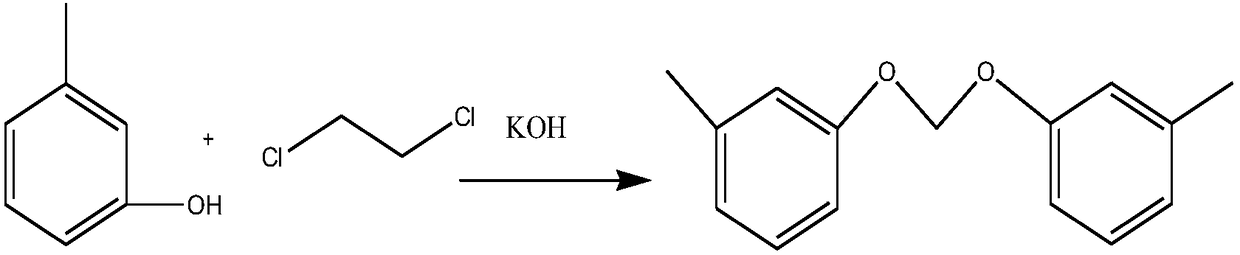

[0021] The reaction formula in the process of preparing 1,2-bis(3-methylphenoxy)ethane thermal sensitizer is as follows:

[0022]

[0023] The molar ratio of m-cresol, dichloroethane and potassium hydroxide in the present invention is...

Embodiment 1

[0027] Add 400 grams of m-cresol and 254 grams of potassium hydroxide with a content of 90% in a 2-liter autoclave, heat up to 130-150°C, stir to dissolve, cool down to below 80°C, and then add 184 grams of 1,2-dichloroethane, After filling the closed autoclave, replace it with nitrogen for three times, then feed a small amount of nitrogen, raise the temperature to 130°C, keep the temperature for 15 hours, and lower it to below 80°C, add water, and keep the temperature at 80-100°C for 1 hour. The temperature was lowered to 5-25° C. to precipitate for more than 3 hours, filtered, rinsed with a small amount of water, and the filter cake was dried to obtain 419.0 g of a white solid product with a content of 99.3% and a yield of 93.5%.

Embodiment 2

[0029] Add 400 grams of m-cresol and 276 grams of potassium hydroxide with a content of 90% in a 2-liter autoclave, heat up to 130-150°C, stir and dissolve, cool down to 80°C, and then add 184 grams of 1,2-dichloroethane, After filling the closed autoclave, replace it with nitrogen for three times, then feed a small amount of nitrogen, raise the temperature to 150°C, keep it warm for 15 hours, then lower it to 70°C, add 1200 ml of water, and keep it at 80-100°C for 1.5 hours. The temperature was lowered to 5-25° C. to precipitate for more than 3 hours, filtered, rinsed with a small amount of water, and the filter cake was dried to obtain 423.5 g of a white solid product with a content of 99.5% and a yield of 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com