Method for preparing high-concentration polyoxy alkyl allyl ether sulfonate

A technology of polyoxyalkylene ether sulfonate and polyoxyalkylene ether, which is applied in the field of preparation of high-concentration polyoxyalkylene ether sulfonate, can solve the problem of uncertain industrial application prospects, inability to obtain high-activity products, It cannot solve the problems of mass transfer and heat transfer, and achieve the effects of suppressing side reactions of hydrolysis, easy separation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

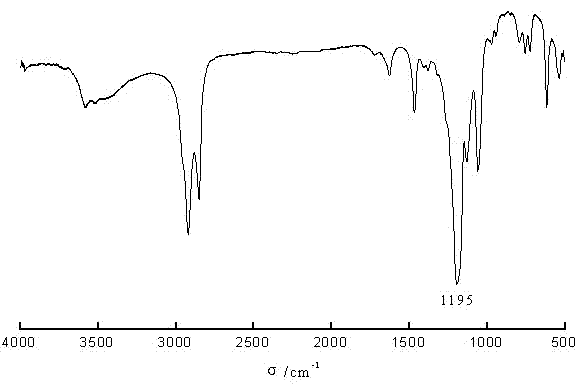

[0026] Implementation example 1: In a 1 L autoclave was added 210 g lauryl polyoxyethylene (3) sodium sulfate, 252 g Na 2 SO 3 , 60 g dodecane, 60 g water, 15 g pentanol, the reaction temperature is 190-195 ℃, the reaction time is 6 h, take it out after cooling, filter out the precipitated inorganic salt, and obtain dodecanol polyoxyethylene ( 3) Sodium sulfonate product, the measured hydrolysis rate is 12%, the sulfonation rate is 87%, and the concentration of sodium lauryl polyoxyethylene (3) ether sulfonate in the obtained reaction product is 53%. Its infrared spectrum is attached figure 1 As shown, it indicates that the raw material lauryl polyoxyethylene (3) sodium sulfate in the microemulsion phase has been completely converted.

Embodiment 2

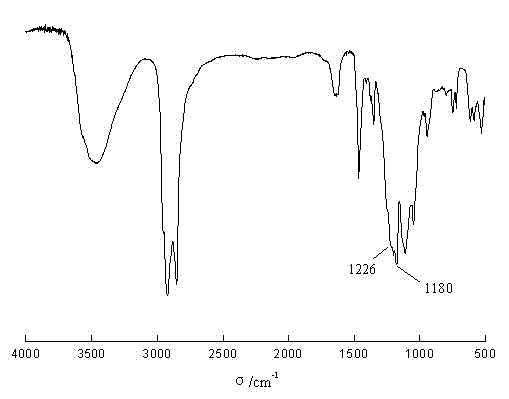

[0028] Implementation Example 2: Add 210 g of n-octanol polyoxyethylene ether (50) sodium sulfate and 86 g of Na in a 1 L autoclave 2 SO 3 , 46 g cyclohexane, 160 g water, 11 g propanol, the reaction temperature is 160-165 ℃, the reaction time is 3 h, take it out after cooling, filter out the precipitated inorganic salt, obtain n-octanol polyoxyethylene ether (50) Sodium sulfonate product, the measured sulfonation rate is 85%, the hydrolysis rate is 9%, and the concentration of sodium n-octanol polyoxyethylene ether (50) sulfonate in the obtained reaction product is 41%.

Embodiment 3

[0029] Implementation Example 3: In a 1 L autoclave was added 210 g isooctanol polyoxyethylene ether (5) ammonium sulfate, 160 g (NH 4 ) 2 SO 3 , 100 g tetradecane, 22 g water, 30 g hexanol, the reaction temperature is 170-175 ℃, the reaction time is 6 h, take it out after cooling, filter out the precipitated inorganic salt, obtain isooctanol polyoxyethylene ether (5) Ammonium sulfonate product, the measured sulfonation rate is 86%, the hydrolysis rate is 11%, and the concentration of isooctanol polyoxyethylene ether (5) ammonium sulfonate in the obtained reaction product is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com