Method for preparing high-concentration polyoxy alkyl allyl ether sulfonate

A technology of polyoxyalkylene ether sulfonate and polyoxyalkylene ether, which is applied in the field of preparation of high-concentration polyoxyalkylene ether sulfonate, can solve the problem of inability to obtain high-activity products, uncertain industrial application prospects, It cannot solve the problems of mass transfer and heat transfer, and achieve the effects of suppressing side reactions of hydrolysis, easy separation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

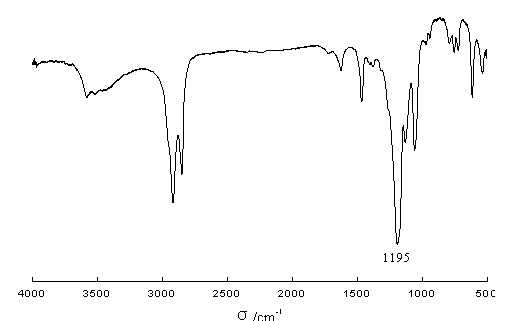

[0026] Implementation example 1: In a 1 L autoclave was added 210 g lauryl polyoxyethylene (3) sodium sulfate, 252 g Na 2 SO 3 , 60 g dodecane, 60 g water, 15 g pentanol, the reaction temperature is 190-195 ℃, the reaction time is 6 h, take it out after cooling, filter out the precipitated inorganic salt, and obtain dodecanol polyoxyethylene ( 3) Sodium sulfonate product, the measured hydrolysis rate is 12%, the sulfonation rate is 87%, and the concentration of sodium lauryl polyoxyethylene (3) ether sulfonate in the obtained reaction product is 53%. Its infrared spectrum is attached figure 1 As shown, it indicates that the raw material lauryl polyoxyethylene (3) sodium sulfate in the microemulsion phase has been completely converted.

Embodiment 2

[0028] Implementation Example 2: Add 210 g of n-octanol polyoxyethylene ether (50) sodium sulfate and 86 g of Na in a 1 L autoclave 2 SO 3 , 46 g cyclohexane, 160 g water, 11 g propanol, the reaction temperature is 160-165 ℃, the reaction time is 3 h, take it out after cooling, filter out the precipitated inorganic salt, obtain n-octanol polyoxyethylene ether (50) Sodium sulfonate product, the measured sulfonation rate is 85%, the hydrolysis rate is 9%, and the concentration of sodium n-octanol polyoxyethylene ether (50) sulfonate in the obtained reaction product is 41%.

Embodiment 3

[0029] Implementation Example 3: In a 1 L autoclave was added 210 g isooctanol polyoxyethylene ether (5) ammonium sulfate, 160 g (NH 4 ) 2 SO 3 , 100 g tetradecane, 22 g water, 30 g hexanol, the reaction temperature is 170-175 ℃, the reaction time is 6 h, take it out after cooling, filter out the precipitated inorganic salt, obtain isooctanol polyoxyethylene ether (5) Ammonium sulfonate product, the measured sulfonation rate is 86%, the hydrolysis rate is 11%, and the concentration of isooctanol polyoxyethylene ether (5) ammonium sulfonate in the obtained reaction product is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com