Assembled haunch support type top and bottom corner steel beam column connecting steel frame

A beam-column connection, steel frame technology, applied in complex mathematical operations, architecture, building structure, etc., can solve problems such as insufficient lateral stiffness and unsuitable reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

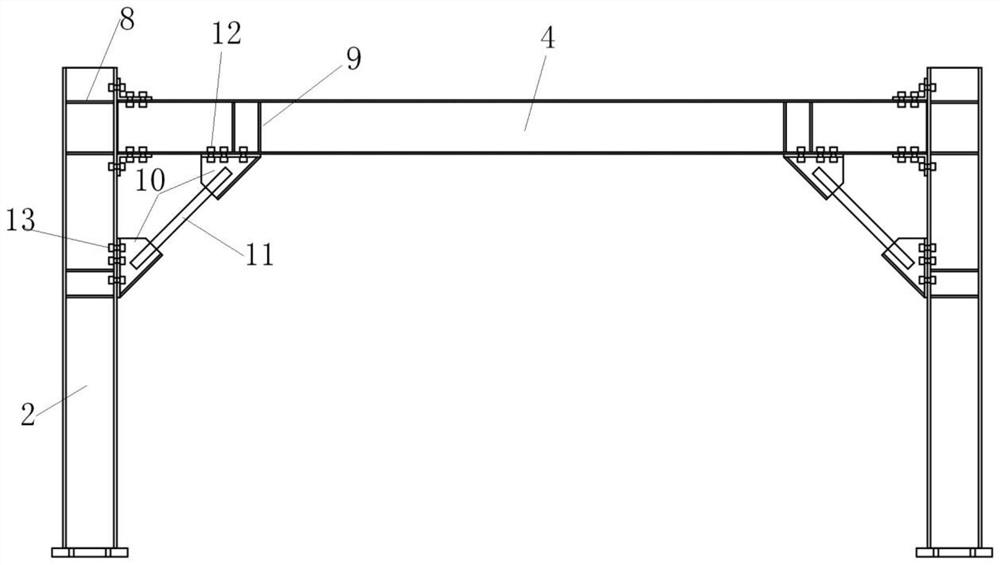

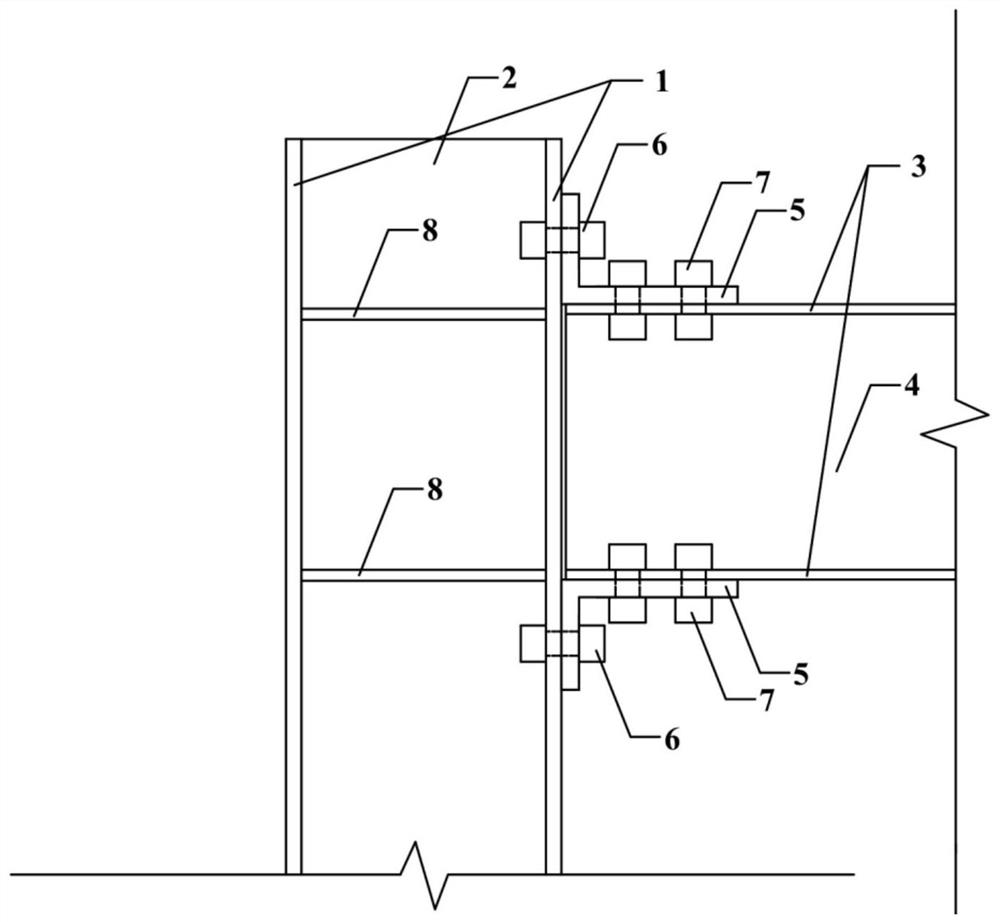

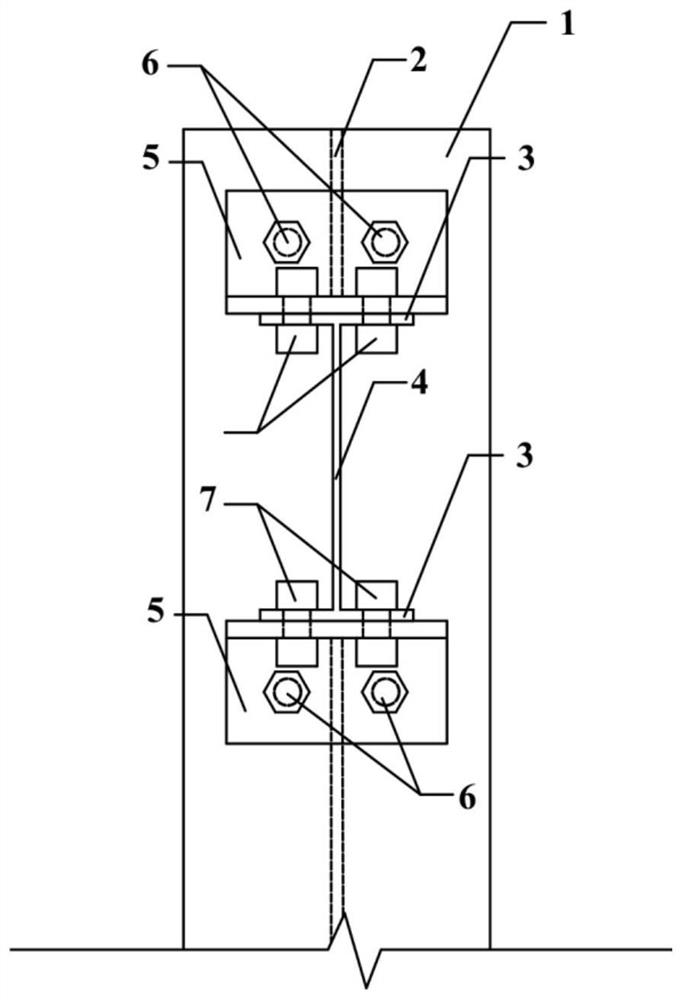

[0075] Such as Figure 1-Figure 10 As shown, the assembled armpit type top and bottom angle steel beam-column connection steel frame provided in this embodiment includes two I-shaped steel columns that are welded by the column flange 1 and the column web 2, and the beam flange 3 and the beam The I-shaped steel beam, the top and bottom angle steel 5, the column stiffener 8, the beam stiffener 9, the gusset plate 10 and the diagonal support 11 formed by welding the web 4 are also equipped with the first bolt 6, the second bolt 7, The third bolt 12 and the fourth bolt 13 .

[0076] The two steel columns are respectively fixedly connected to the two ends of the steel beam through the top and bottom angle steel 5, and arm braces are arranged near the connection between the steel beam and the two steel columns, and each arm brace includes a diagonal support 11 and is fixedly arranged on The gusset plates 10 at both ends of the diagonal brace 11 are detachably connected to the steel...

Embodiment 2

[0110] Basically the same as Embodiment 1, the difference between this embodiment and Embodiment 1 is:

[0111] The yield mechanism of the steel frame with hip-braced top-bottom angle steel beam-column connection is that the steel beam yields before the beam-column connection and the hip brace.

[0112] Further, the axial tensile force on the armpit formed by the gusset plate 10 and the circular tube support 11 is obtained by the following formula:

[0113]

[0114] m C ≤M cy

[0115] In the formula: M by is the yield bearing capacity of the beam (take the yield stress σ of the steel y and section moment Z b product), M bp is the ultimate bearing capacity of the beam (take the yield stress σ of the steel y and the plastic section moment Z bp product), M c is the semi-rigid connection bending moment, M cy is the yield bearing capacity of the joint, P c is the axial tension on the armpit support, P ty is the yield bearing capacity of the haunch, W is the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com