Spring steel austenite grain size detection method

A technology for austenite grains and detection methods, applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as unsatisfactory results, achieve simple and easy access to raw materials and equipment, and high measurement accuracy , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The tested spring steel grades are listed in Table 1. The detection steps include:

[0023] (1) Take a spring steel wire rod with a length of 200 mm and straighten it;

[0024] (2) Put the wire rod into a heating furnace at 860℃ for 60min, put it into fast-flowing water for quenching to obtain a complete martensitic structure, and cut a 1-2mm deep crack in the middle of the heat-treated sample for use;

[0025] (3) The cotton soaked in 15% dilute sulfuric acid solution is taken out and placed on the grid until no dilute sulfuric acid solution drips; Seal the package with tape, remove the tape and cotton after 24 hours, wash the sample with alcohol and blow dry; tap the opposite side of the sample crack with a hammer, and the sample will break along the crack. Quickly ultrasonically clean the fracture with alcohol, and dry it immediately after cleaning;

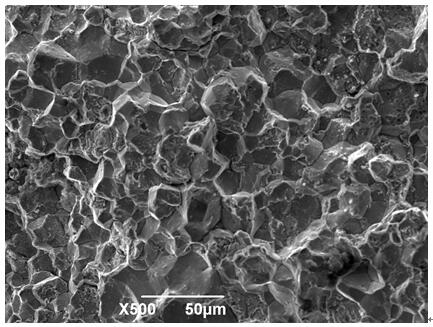

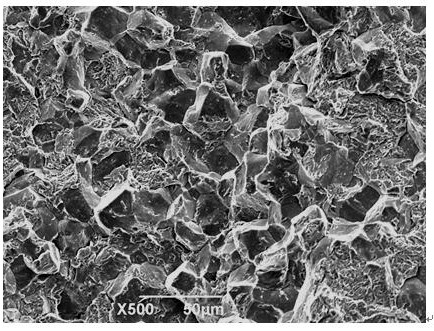

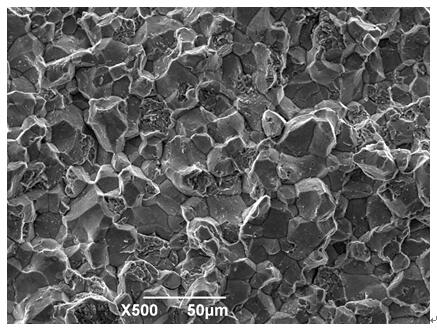

[0026] (4) Observe the fracture with the secondary electron image of the scanning electron microscope. The inspec...

Embodiment 2

[0034] The tested spring steel grades are listed in Table 1. The detection steps include:

[0035] The detection steps include:

[0036] (1) Take a spring steel wire rod with a length of 180 mm and straighten it;

[0037] (2) Put the wire rod into a heating furnace at 860℃ for 60min, put it into fast-flowing water for quenching to obtain a complete martensitic structure, and cut a 1-2mm deep crack in the middle of the heat-treated sample for use;

[0038] (3) The cotton soaked in 15% dilute sulfuric acid solution is taken out and placed on the grid until no dilute sulfuric acid solution drips; Seal the package with tape, remove the tape and cotton after 28 hours, wash the sample with alcohol and blow dry; tap the opposite side of the crack of the sample lightly with a hammer, and the sample will break along the crack. Quickly ultrasonically clean the fracture with alcohol, and dry it immediately after cleaning;

[0039] (4) Observe the fracture with the secondary electron ...

example 2

[0041] The tested spring steel grades are listed in Table 1. The detection steps include:

[0042] (1) Take a spring steel wire rod with a length of 180 mm and straighten it;

[0043] (2) Put the wire rod into a heating furnace at 860℃ for 60min, put it into fast-flowing water for quenching to obtain a complete martensitic structure, and cut a 1-2mm deep crack in the middle of the heat-treated sample for use;

[0044] (3) Load the opposite side of the crack of the sample with impact load, so that the sample breaks along the crack, quickly clean the fracture with alcohol by ultrasonic wave, and dry it immediately after cleaning;

[0045] (4) Observe the fractures with the secondary electron image of the scanning electron microscope, and it can be found that most of the fractures are intergranular fractures, and the grain boundary recognition rate is about 65%. In the method of 8.3.2 straight line intercept point, on the fracture picture, several straight lines are used to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com