Unattended machining method for numerical control machining equipment

A technology of processing equipment and processing methods, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve problems such as difficult to activate employees' labor enthusiasm and creativity, expensive production line construction, and large number of multi-shift personnel, etc., to achieve The effective running time of the equipment is extended, the processing time of the equipment is not enough, and the effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

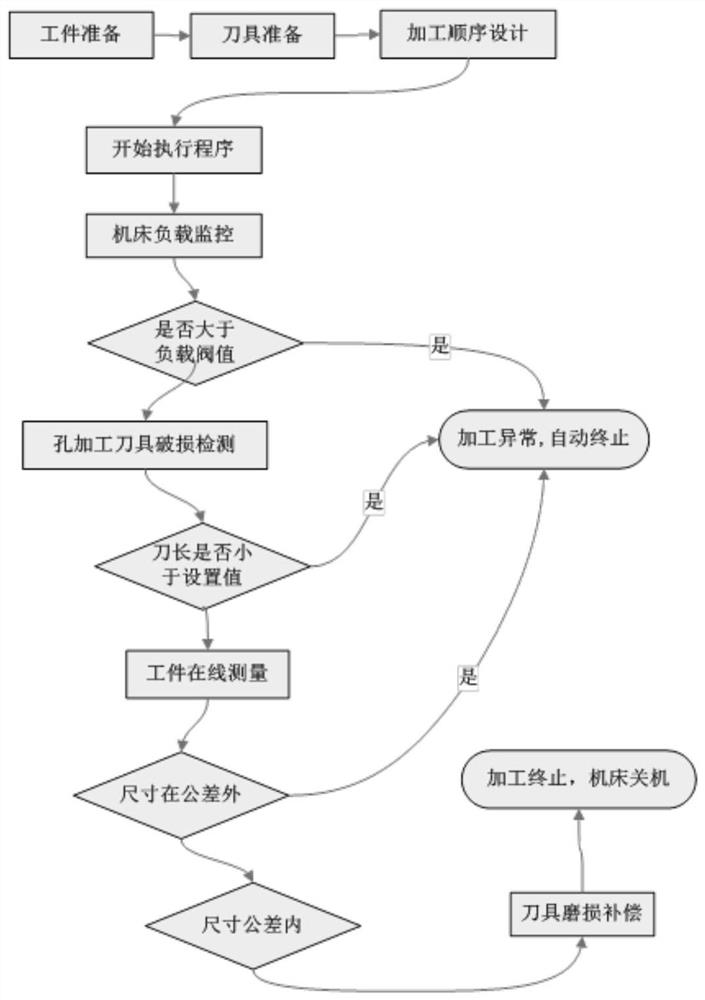

[0012] Under normal circumstances, when CNC equipment is being processed, the operator is next to the equipment and is mainly responsible for real-time detection of part size, exception handling, coordinate system confirmation, tool maintenance, and equipment shutdown. For unattended operation, it is necessary to solve related operation and safety production problems through technical means, that is, the unattended processing mode needs to solve the continuity of production and the safety of processing process.

[0013] The continuity of production includes being able to set up the chuck at one time so that the CNC equipment has enough processing tasks at night, or use automated equipment to solve the loading and unloading of workpieces. When part of the process has a lot of processing content, for example, the processing time of a process is more than 8 hours, it is not necessary to load the parts frequently, and the parts can be loaded in the middle process by personnel; for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com