A Robust Predictive Sensorless Controller for Permanent Magnet Synchronous In-wheel Motor

An in-wheel motor, permanent magnet synchronous technology, applied in motor generator control, electronic commutation motor control, control of electromechanical brakes, etc., can solve problems such as rotor position and speed estimation error, sensor accuracy reduction, and motor parameter mismatch. , to achieve the effect of improving control accuracy and speed, overcoming cost increase and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

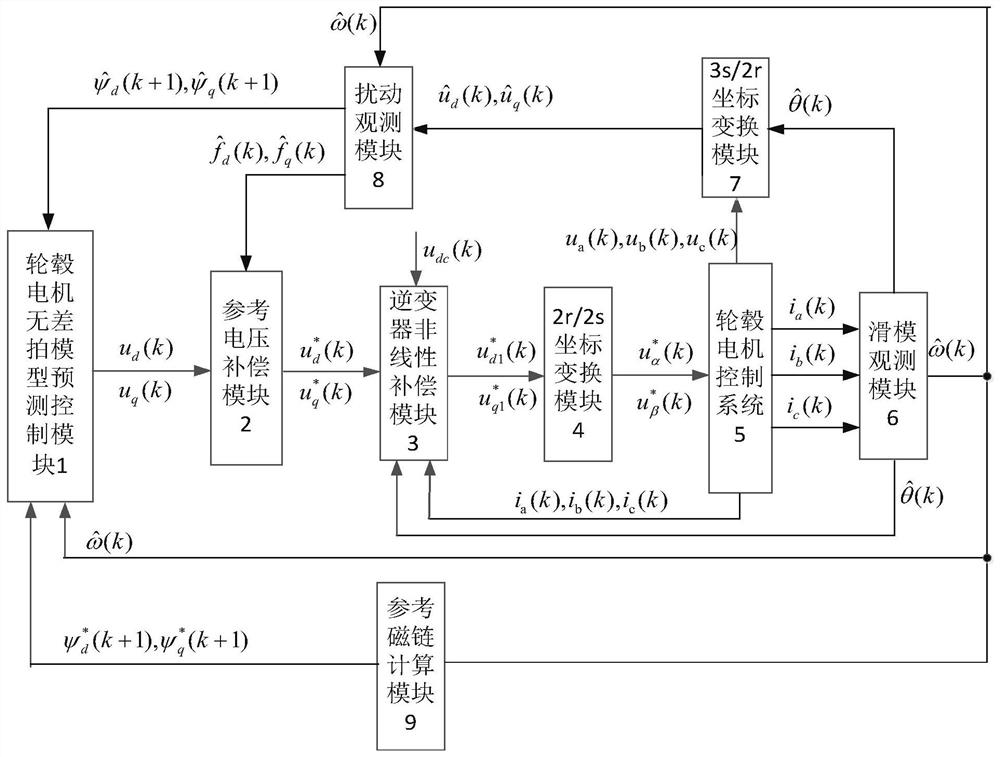

[0018] Such as figure 1 Shown is the sensorless controller for robust predictive permanent magnet synchronous in-wheel motor proposed by the present invention, which consists of in-wheel motor deadbeat model predictive control module 1, reference voltage compensation module 2, and inverter nonlinear compensation modules 3 and 2r / 2s coordinate transformation module 4, sliding mode observation module 6, 3s / 2r coordinate transformation module 7, disturbance observation module 8 and reference flux linkage calculation module 9. The sensorless controller is connected with the hub motor control system 5 to control the hub motor control system 5 .

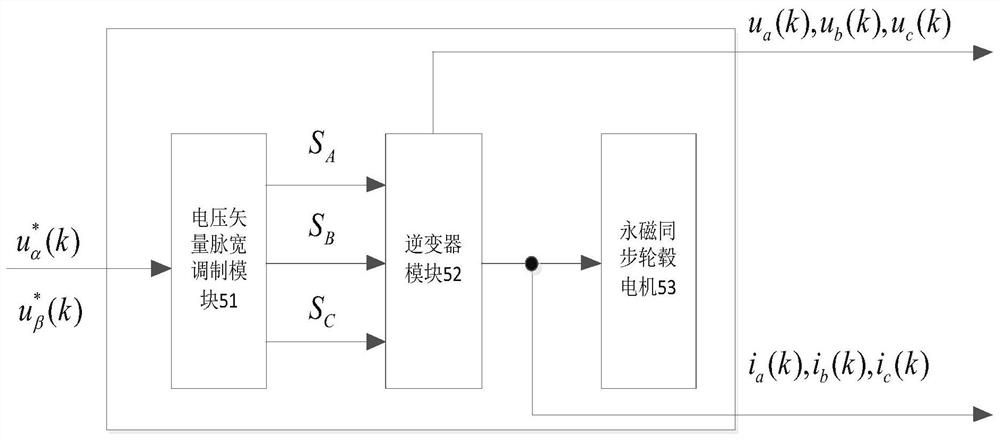

[0019] combine figure 2 , the in-wheel motor control system 5 is composed of a voltage vector pulse width modulation module 51, an inverter module 51 and a permanent magnet synchronous in-wheel motor 53 in series. The input of the in-wheel motor control system 5 is the reference voltage in the two-phase stationary coordinate system T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com