Grain warehousing equipment

A grain and equipment technology, applied in the field of grain warehousing equipment, can solve the problems of high cost of nitrogen atmosphere equipment, inability to kill pests, and inability to lower the temperature of the whole warehouse, so as to reduce multi-process operation of grain, reduce labor output, The effect of preventing a large amount of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

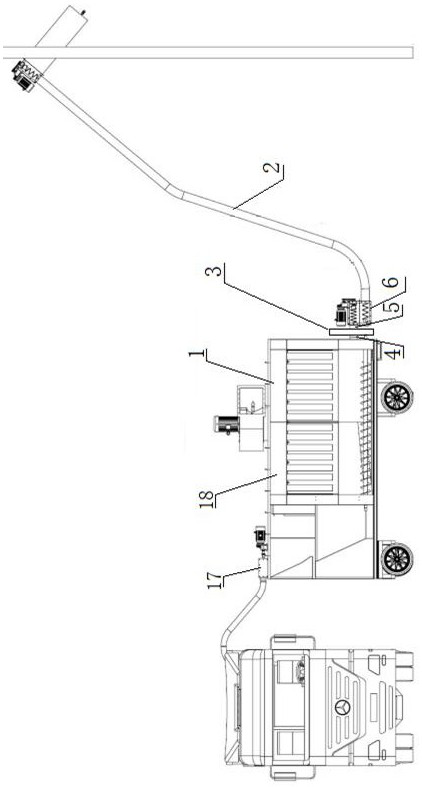

[0035] see Figure 1-4, the present invention provides the following technical solutions: comprising a mobile extraction vehicle 1, a granary entry lifting auger 2, and an insecticidal assembly 3, one end of the mobile extraction vehicle 1 is fixed with a grain outlet 4, and the end 4 of the mobile extraction vehicle 1 is fixed with a mobile extraction The feeding assembly 17 at the top of the car 1 is also provided with a dust removal assembly 18 inside. The 4 ends of the grain outlet are detachably connected to the insecticidal assembly 3, and the 4 ends of the insecticidal assembly 3 are away from the grain outlet. 5 The other end is detachably connected with the lifting auger inlet 6, and the other end of the lifting auger inlet 6 is connected to the granary feeding elevator 2, and the grain outlet 4 and the lifting auger inlet 6 are fixed with threads interface19.

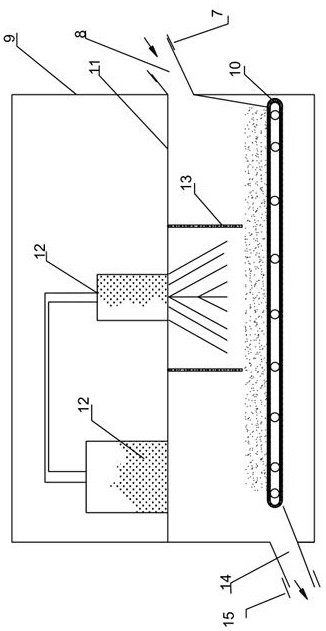

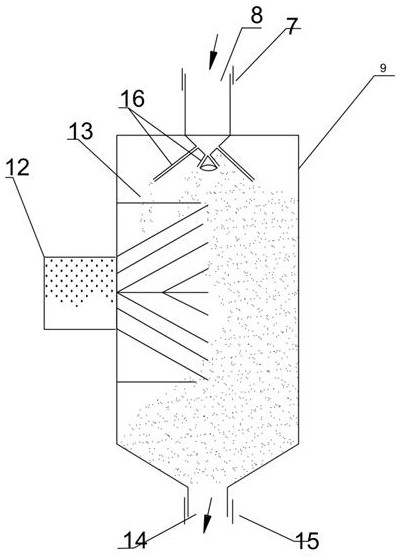

[0036] Such as figure 2 In the illustrated embodiment, the insecticidal assembly 3 includes a first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com