Efficient stone crushing and screening device for constructional engineering

A technology of construction engineering and screening device, which is applied in the direction of grain processing, etc., can solve the problems of uneven size and low crushing efficiency, and achieve the effect of uniform size, good crushing effect, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

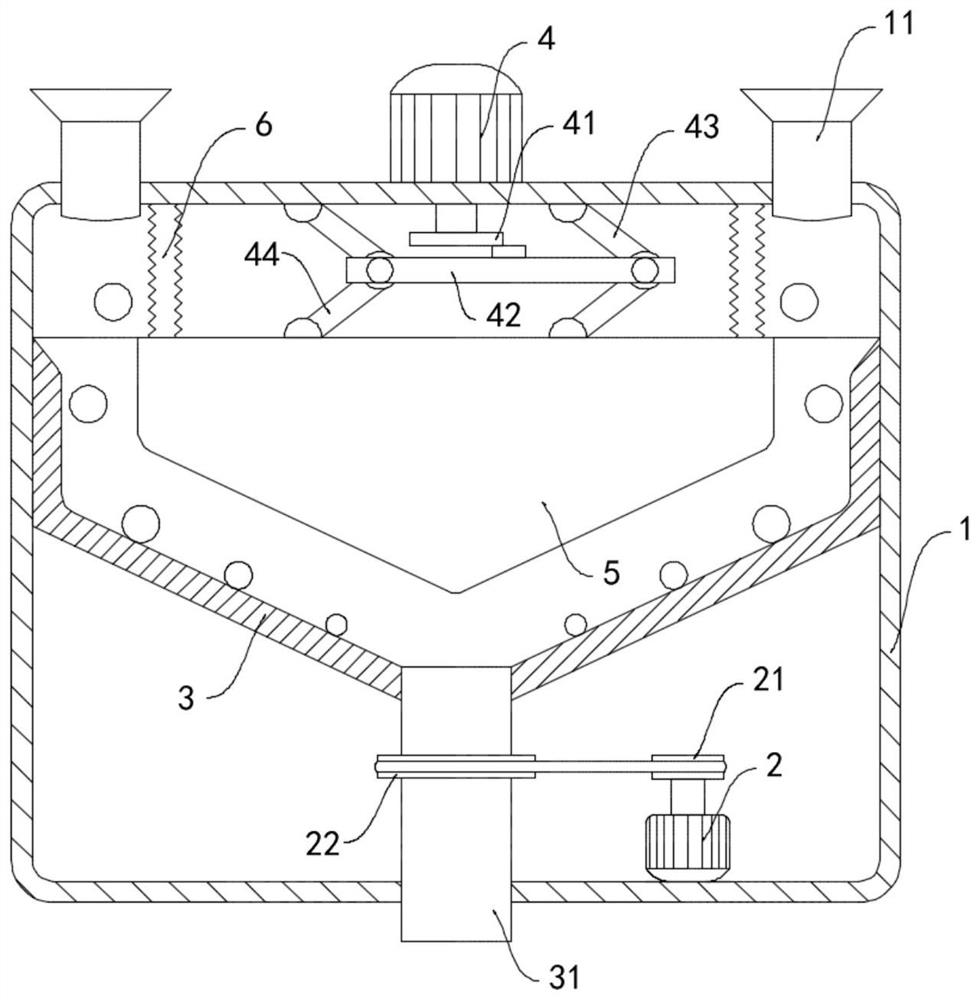

[0021] like figure 1 As shown, a high-efficiency gravel screening device for construction engineering includes a device housing 1, the upper end of the device housing 1 is connected with a feed hopper 11, the inner bottom surface of the device housing 1 is equipped with a first motor 2, and the device housing The inner wall of the body 1 is rotatably connected with a gravel cylinder 3, the center of the bottom of the gravel cylinder 3 is sunken downwards and is fixedly connected with a discharge pipe 31, and the lower end of the discharge pipe 31 runs through the bottom surface of the device housing 1 And connected with the device housing 1 in rotation, the first motor 2 is connected with the transmission of the gravel cylinder 3, the output shaft of the first motor 2 is fixedly sleeved with the first pulley 21, and the outer discharge pipe 31 is fixedly sleeved with the second belt pulley. The belt pulley 22, the first belt pulley 21 and the second belt pulley 22 are connecte...

Embodiment 2

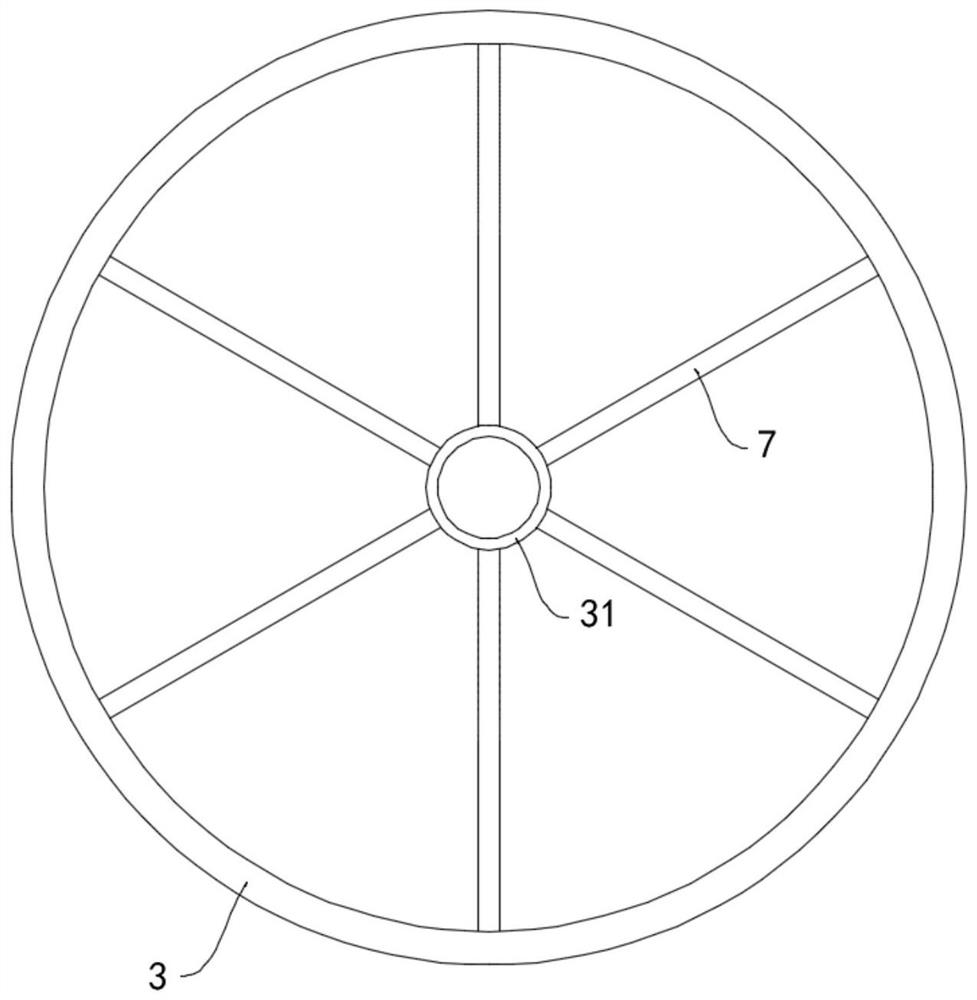

[0027] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the inner bottom surface of the gravel cylinder 3 is fixedly connected with a plurality of protruding ribs 7 extending from the center to the surroundings, and the plurality of protruding ribs 7 are in an annular array. arranged.

[0028] In this embodiment, when the stone rolls on the inner bottom surface of the crushing cylinder 3, the raised ribs 7 rotate with the crushing cylinder 3 to further impact and crush the stone, and at the same time, the stone is easy to bounce under the impact of the raised ribs 7 After falling, its shattering effect has been improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com