Universal type lifting pipe robot automatic TIG welding tool and welding method thereof

A technology for welding tooling and water pipes, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as poor coaxiality between round pipes and flanges, low efficiency of product changeover and adjustment, and uncontrollable production costs. Achieve the effect of improving welding quality and quality stability, improving production efficiency, ensuring dimensional accuracy and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

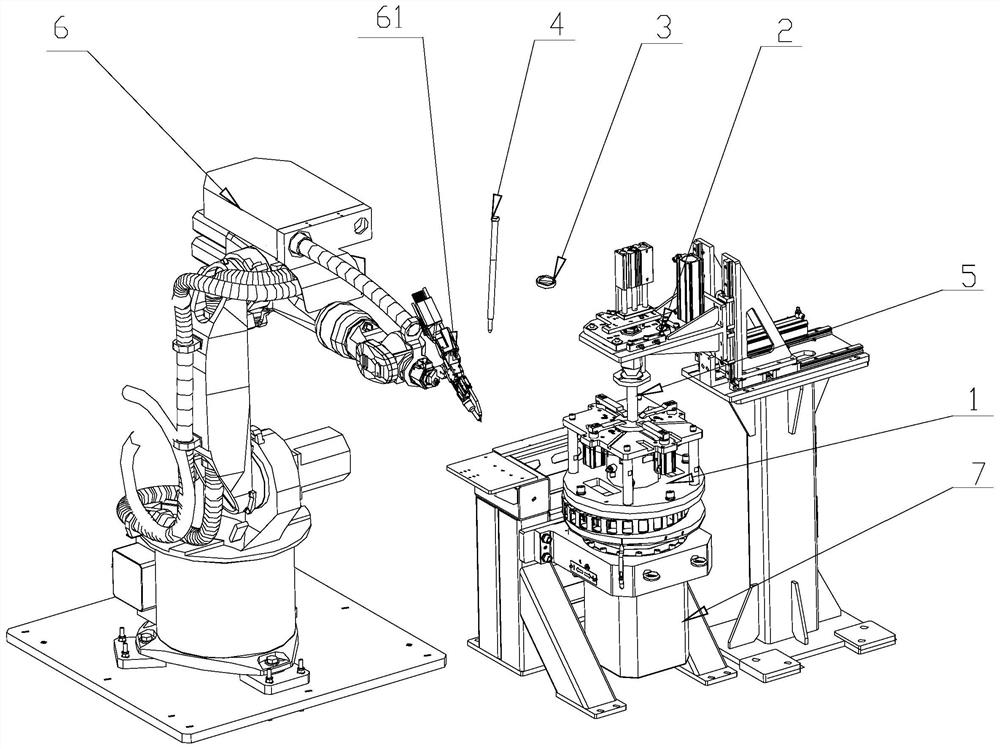

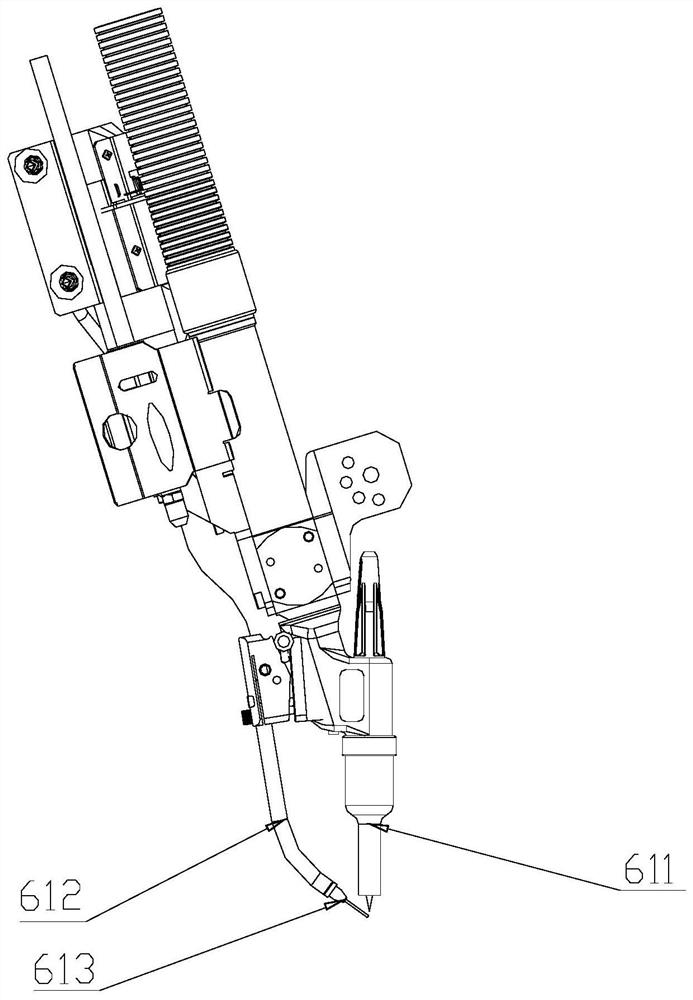

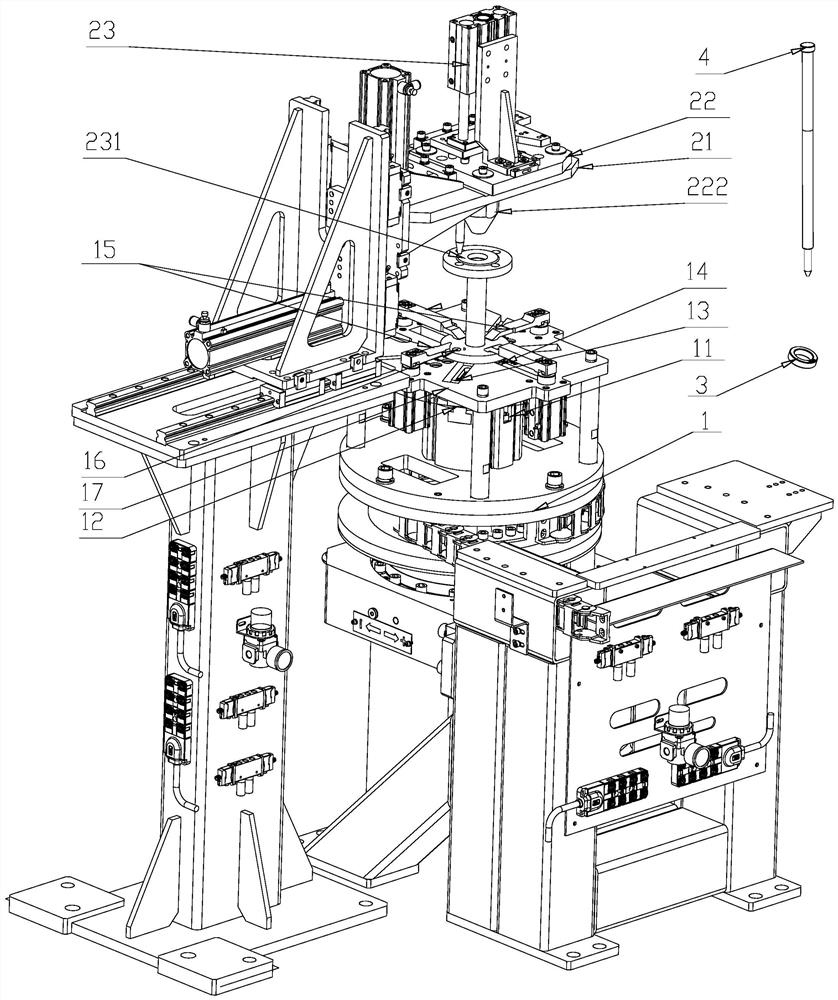

[0049] A general automatic TIG welding tool for a water pipe robot, used for welding a water pipe assembly 5, the structure of the water pipe assembly 5 is as follows Figure 4A , Figure 4B As shown, it is composed of flanges 51 at the upper and lower ends and a round pipe 52 in the middle. 8mm. The welding process of this welding tool is as follows: first weld a flange 51 and a round pipe 52 at one end on a set of this welding tool without a plug-in mechanism to form a semi-finished workpiece of a water pipe assembly 5, that is, the welded flange in the previous process 53, and then the welded flange 53 in the previous process is grasped by a fully automatic truss gripper and rotated 180° in space, and transferred to another set of this welding tool with a plug-in pin mechanism, and placed on the new welding tool The other end flange 51 groups are butt-welded into the finished workpiece of the water pipe assembly 5. The diameter of the center hole of the flange of the wat...

Embodiment 2

[0077] The support plate 17 of the welding table is provided with six mounting holes 171 for flange positioning pins. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com