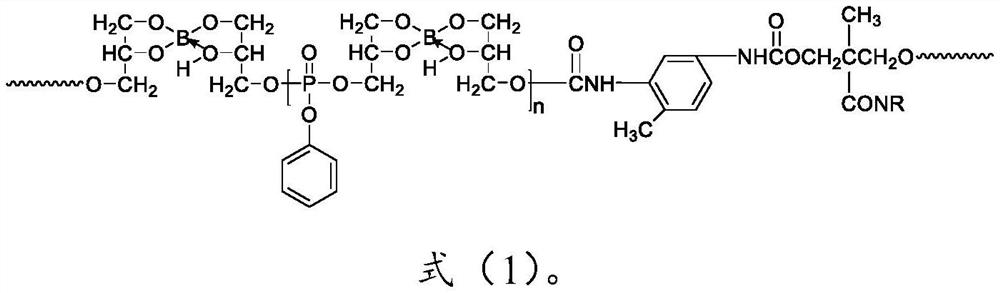

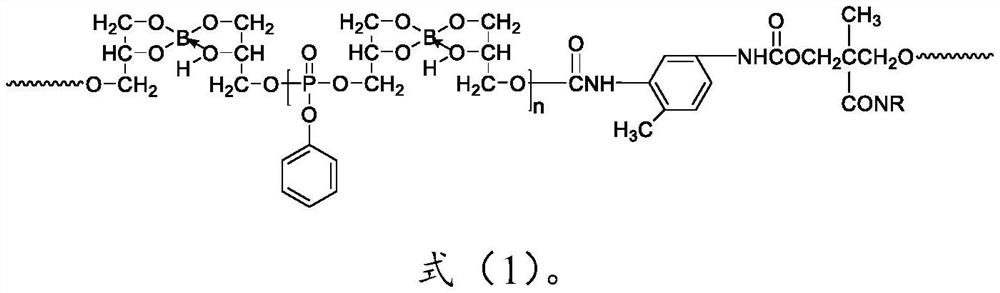

Phosphorus-boron heterochain hydroxyl-terminated prepolymer block polyurethane copolymer water-based printing and dyeing fireproof coating and preparation method and application thereof

A technology of fire-resistant coatings and prepolymers, which is applied in the direction of dyeing, flame-retardant fibers, and liquid-repellent fibers, and can solve problems such as attenuation of flame-retardant effects, high specific gravity, and intolerance to organic media.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

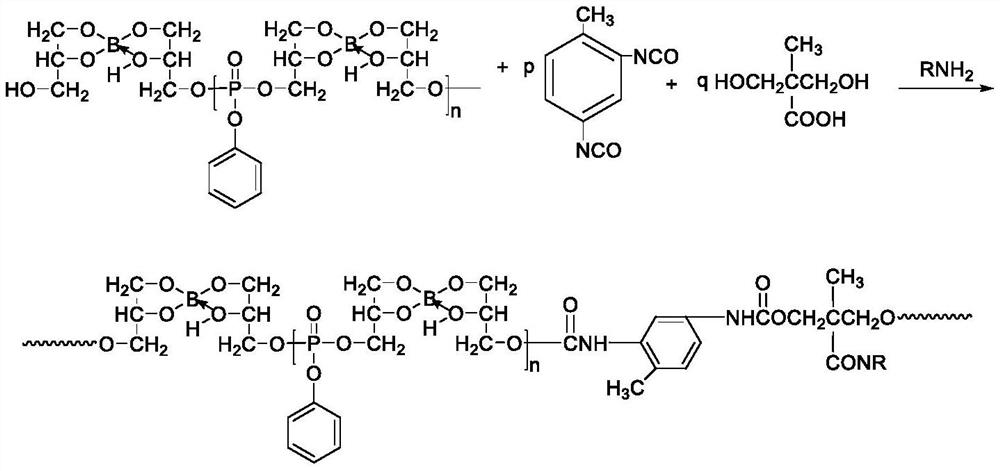

[0052] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0053] (1) In a four-necked flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml of xylene, 75.9g of PDCP-DGB, dilaurel with a ratio of 1:0.03 to TDI dibutyltin acid.

[0054] (2) Turn on stirring and blow nitrogen, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 17.3g TDI and 6.8g DMPA dropwise within 30 minutes to keep the system temperature at 75±1°C. Insulate for 2 hours, separate and recover the upper xylene.

[0055] (3) Cool down the reaction system in step (2) to 45±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust the pH to 9.0, stop stirring and discharge, and obtain the phosphobora chain prepolymer intercalated Segment polyurethane waterborne copolymer. ...

no. 2 example

[0060] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0061] (1) In a four-necked flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml of xylene, 76.9g of PDCP-DGB, dilaurel with a ratio of 1:0.02 to TDI dibutyltin acid.

[0062] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 65±1°C in a water bath. After the heat preservation system is uniform, add 16.2g TDI and 6.9g DMPA dropwise within 30 minutes, and keep the system temperature at 70±1°C. Insulate for 2 hours, separate and recover the upper xylene.

[0063] (3) Cool the reaction system in step (2) to 40±1°C, then add monoethanolamine and 50ml of water, continue to stir for 1 hour, adjust the pH=8.0, stop stirring and discharge, and obtain the phosphobora chain prepolymer intercalated Segment polyurethane waterborne copolymer.

[0064]...

no. 3 example

[0068] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0069] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml xylene, 76.0g PDCP-DGB, dilaurel with a ratio of 1:0.01 to TDI dibutyltin acid.

[0070] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 65±1°C in a water bath. After the heat preservation system is uniform, add 17.0g TDI and 6.8g DMPA dropwise within 30 minutes, and keep the system temperature at 75±1°C. Keep warm for 1.5h, separate and recover the upper xylene.

[0071] (3) Cool the reaction system in step (2) to 40±1°C, then add monoethanolamine and 50ml of water, continue to stir for 1 hour, adjust the pH to 7.5, stop stirring and discharge, and obtain the phosphobora chain prepolymer intercalated Segment polyurethane waterborne copolymer.

[0072] 2. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com