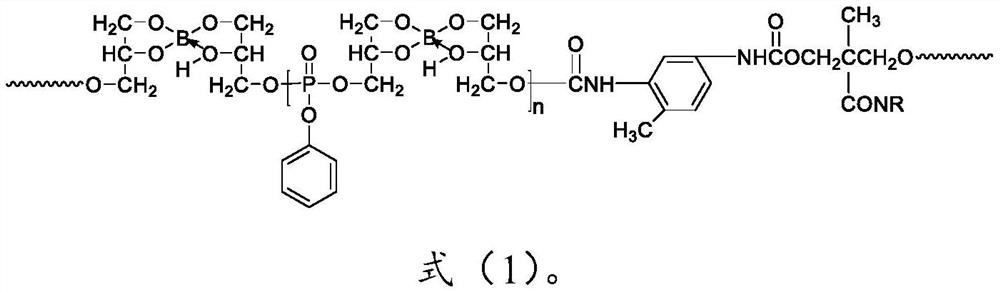

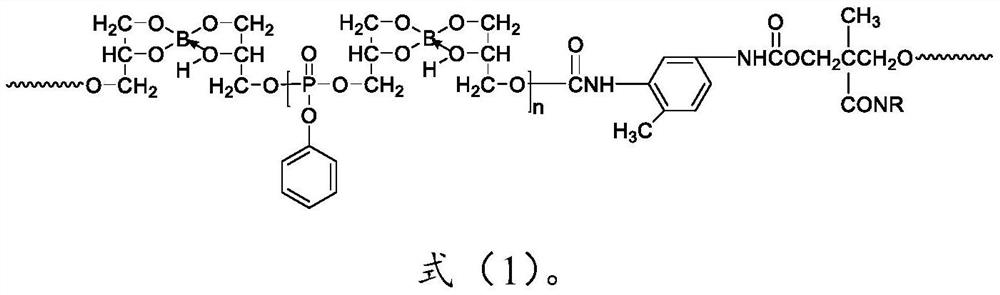

Phosphorus-boron heterochain prepolymer block polyurethane water-based damp-proof flame-retardant carton film coating agent as well as preparation method and application thereof

A technology of prepolymer and film coating agent, applied in fire retardant addition, papermaking, paper and other directions, can solve the problems of low durability, large migration, decreased water and moisture resistance, etc., and achieve long-term effective waterproof properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

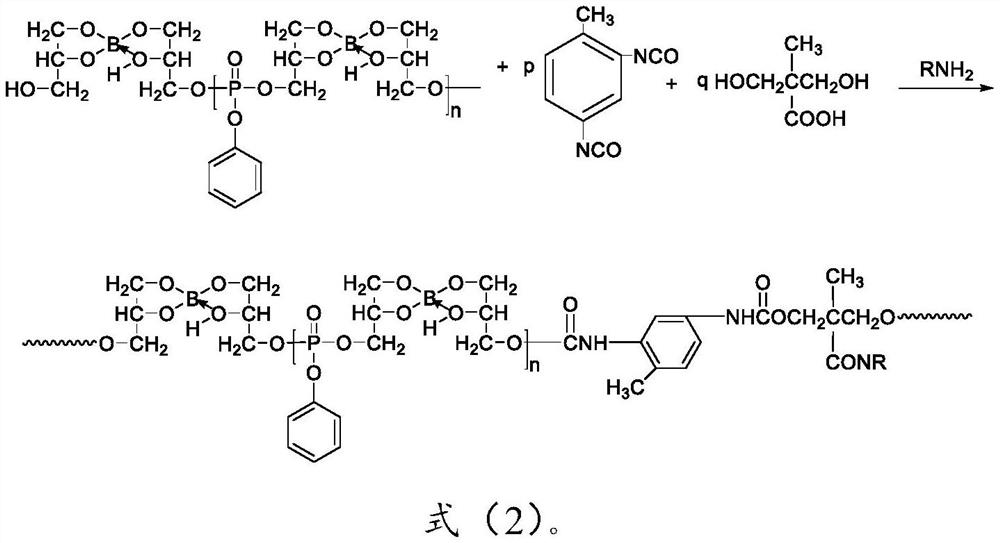

Method used

Image

Examples

no. 1 example

[0054] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0055] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml xylene, 100g PDCP-DGB, dilauric acid with a ratio of 1:0.01 to TDI Dibutyltin.

[0056] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 21.5g TDI and 9.5g DMPA dropwise within 30 minutes to keep the system temperature at 75±1°C. Insulate for 2 hours, separate and recover the upper xylene.

[0057] (3) Cool the reaction system in step (2) to 45±1°C, then add monoethanolamine and 50ml of water, continue to stir for 1 hour, adjust the pH=9.0, and adjust the product viscosity to 2500Cp (25°C) with water, that is Obtain the phosphorus bora chain prepolymer block polyurethane aqueous copolyme...

no. 2 example

[0062] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0063] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 100ml xylene, 100g PDCP-DGB, dilauric acid with a ratio of 1:0.02 to TDI Dibutyltin.

[0064] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 65±1°C in a water bath. After the heat preservation system is uniform, add 21.5g TDI and 10.5g DMPA dropwise within 30 minutes to keep the system temperature at 70±1°C. Keep warm for 2.5h, separate and recover the upper xylene.

[0065] (3) Cool down the reaction system in step (2) to 45±1°C, then add monoethanolamine and 150ml of water, continue stirring for 1 hour, adjust the pH=8.0, and adjust the product viscosity to 3000Cp (25°C) with water, that is Obtain the phosphorus bora chain prepolymer block polyurethane aqueous c...

no. 3 example

[0070] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0071] (1) In a four-necked flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 150ml xylene, 100g PDCP-DGB, dilauric acid with a ratio of 1:0.03 to TDI Dibutyltin.

[0072] (2) Turn on stirring and blow nitrogen, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 20.5g TDI and 9.5g DMPA dropwise within 30 minutes to keep the system temperature at 75±1°C. Keep warm for 1.5h, separate and recover the upper xylene.

[0073] (3) Cool down the reaction system in step (2) to 50±1°C, then add monoethylamine and 150ml of water, continue to stir for 1h, adjust the pH=7.5, and then adjust the product viscosity to 3500Cp (25°C) with water, That is, the phosphorus bora chain prepolymer block polyurethane water-based cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com