A tunnel steel frame support structure and construction method

A technology for supporting structures and tunnels, which is applied in tunnels, earthwork drilling, tunnel lining, etc. It can solve the problems of inconvenient use and a large amount of manpower input, and achieve the effect of simplifying the installation steps and reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions in this application will be further described in detail below in conjunction with the accompanying drawings.

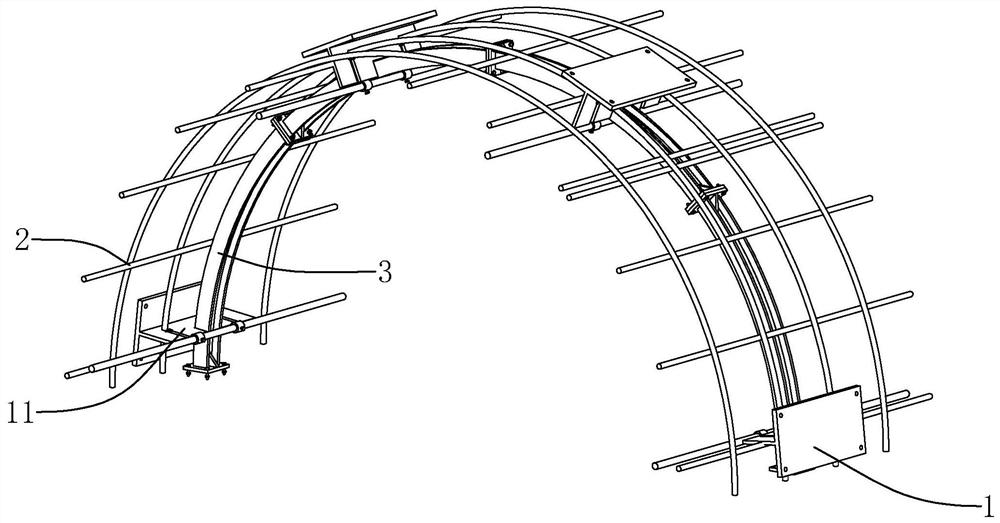

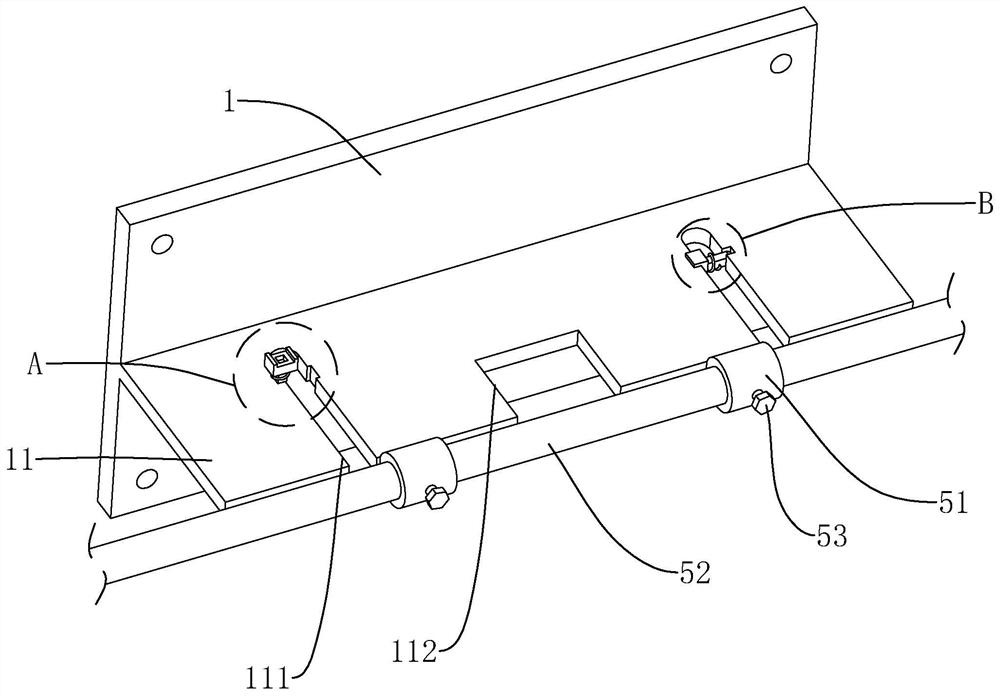

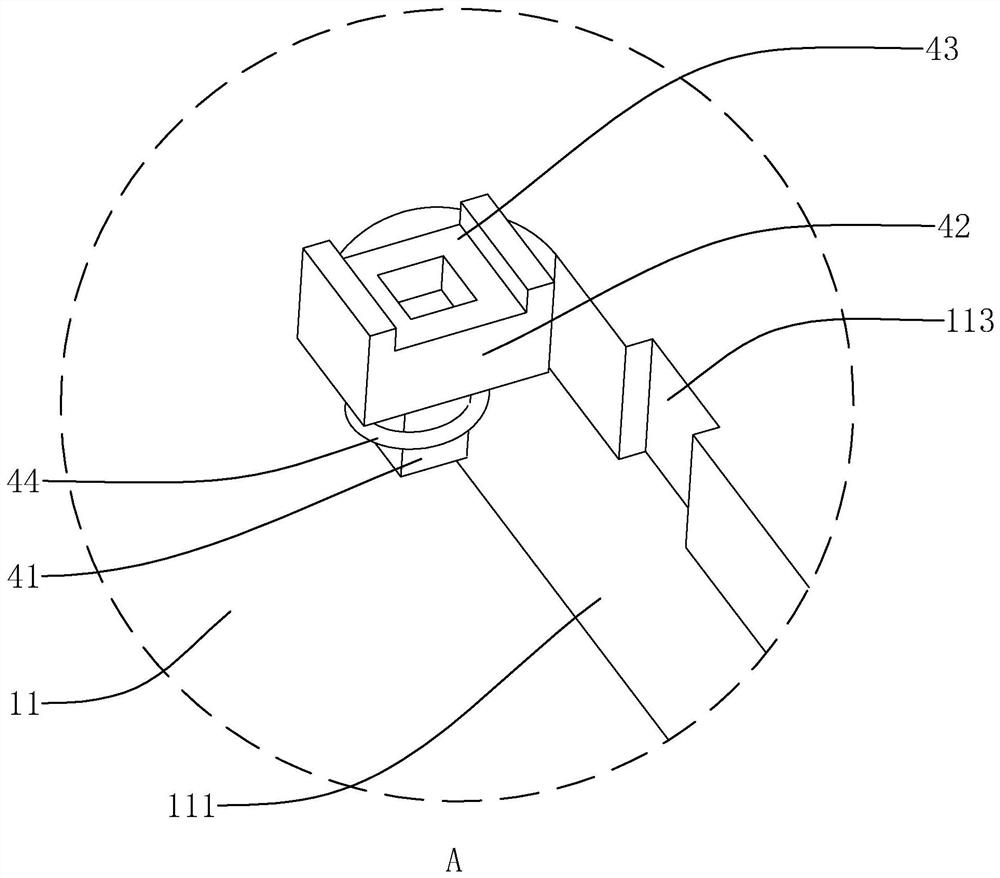

[0044] The embodiment of the present application discloses a tunnel steel frame support structure. Please refer to figure 1 and figure 2 A tunnel steel frame support structure includes a positioning seat 1, a steel mesh 2 and a steel beam 3. A positioning plate 11 is fixedly arranged on the positioning seat 1 , and the surface where the positioning plate 11 is located is perpendicular to the surface where the positioning seat 1 is located. A through hole for the grouting anchor to pass is opened on the positioning seat 1 . After the grouting anchor is fixed on the tunnel, pass the exposed part of the grouting anchor through the via hole, install a nut on the grouting anchor, and use the nut to press the positioning seat 1 on the tunnel. The positioning seat 1 is elongated along the excavation direction of the tunnel, and is evenly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com