Carbon fiber composite transmission shaft joint structure

A composite material and joint structure technology, applied in the directions of shafts and bearings, shafts, couplings, etc., can solve the problems of poor pressure resistance, short service life of the main body of the transmission shaft, inconvenient replacement of the main body of the transmission shaft, etc. The effect of connection stability and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

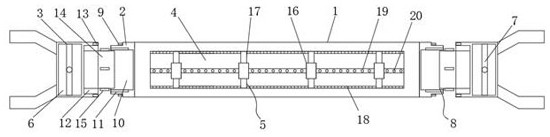

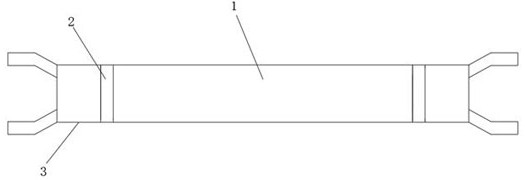

[0022] Embodiment one, by figure 1 , figure 2 and image 3 Given, the present invention comprises a transmission shaft main body 1, two ends of the transmission shaft main body 1 are symmetrically provided with a transmission shaft connecting body 2, both ends of the transmission shaft connecting body 2 are connected with universal joint joints 3, and the inside of the transmission shaft main body 1 A hollow groove 4 is provided. Through the design of the hollow groove 4, the weight of the main body 1 of the transmission shaft is effectively reduced. The inside of the hollow groove 4 is equidistantly provided with reinforcement components 5. Through the connection of the reinforcement components 5 , effectively improving the strength of the transmission shaft main body 1, the interior of the universal joint joint 3 is provided with a cavity groove 2 6, and the interior of the cavity groove 2 6 is provided with a first reinforcing rod 7, and the transmission shaft connecting ...

Embodiment 2

[0023] Embodiment two, on the basis of embodiment one, by figure 1 and figure 2 Given, the joint component 8 includes a joint component 1 and a joint component 2, the joint component 1 is installed on the transmission shaft connecting body 2, and the joint component 2 is mounted on the universal joint 3, so as to facilitate the transmission shaft main body 1 and the universal joint joint 3 connections.

Embodiment 3

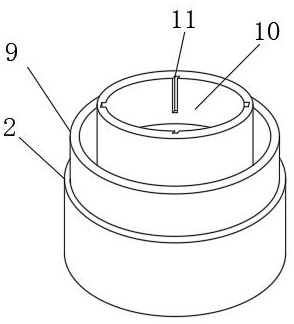

[0024] Embodiment three, on the basis of embodiment two, by figure 1 and image 3 Given, the joint assembly includes a snap ring 9, a joint groove 10 and an insertion groove 11, the snap ring 9 is installed on the transmission shaft connecting body 2, and the middle position of the transmission shaft connecting body 2 is provided with a joint groove 10, An insertion groove 11 is formed around the inner wall of the connecting groove 10, so as to facilitate the connection between the transmission shaft main body 1 and the universal joint 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com