Energy-saving boiler flue gas waste heat recovery equipment

A waste heat recovery equipment, boiler flue gas technology, applied in lighting and heating equipment, combustion equipment, water heaters and other directions, can solve the problems of pollution, affecting all walks of life, heat energy waste, etc., to improve combustion efficiency, prevent slipping and collapse , Improve the effect of grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

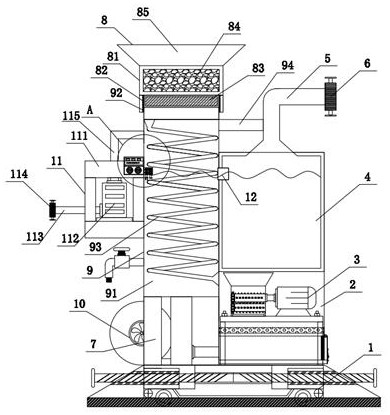

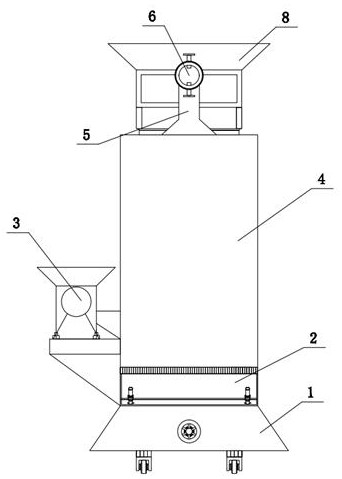

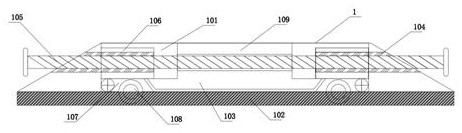

[0037] see Figure 1-7 , an energy-saving boiler flue gas waste heat recovery equipment, including a mobile base 1, a combustion mechanism 2 is fixedly installed on the back of the top right side of the mobile base 1, and a crushing mechanism 3 is fixedly installed on the bottom of the front of the combustion mechanism 2. A boiler body 4 is fixedly installed on the top of the combustion mechanism 2, and an exhaust port 5 is fixedly installed in the middle of the top of the boiler body 4, and a first connecting valve 6 is provided at the end of the exhaust port 5, and the top of the mobile base 1 A support frame 7 is fixedly installed on the left side, and a blower 10 is fixedly installed inside the support frame 7, and the output end of the blower 10 is connected to the left side of the combustion mechanism 2, and a waste heat recovery device 9 is fixedly installed on the top of the support frame 7, An air purification device 8 is threadedly connected to the top of the waste h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com