A drying device with three-dimensional floating function and its implementation method

A technology of drying equipment and functions, which is used in drying cargo handling, drying solid materials, lighting and heating equipment, etc., can solve the problems of inability to manually control all-round drying of materials, uncontrollable material running trajectories, poor drying effect, etc. The effect of running path length, improving drying efficiency, and prolonging drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

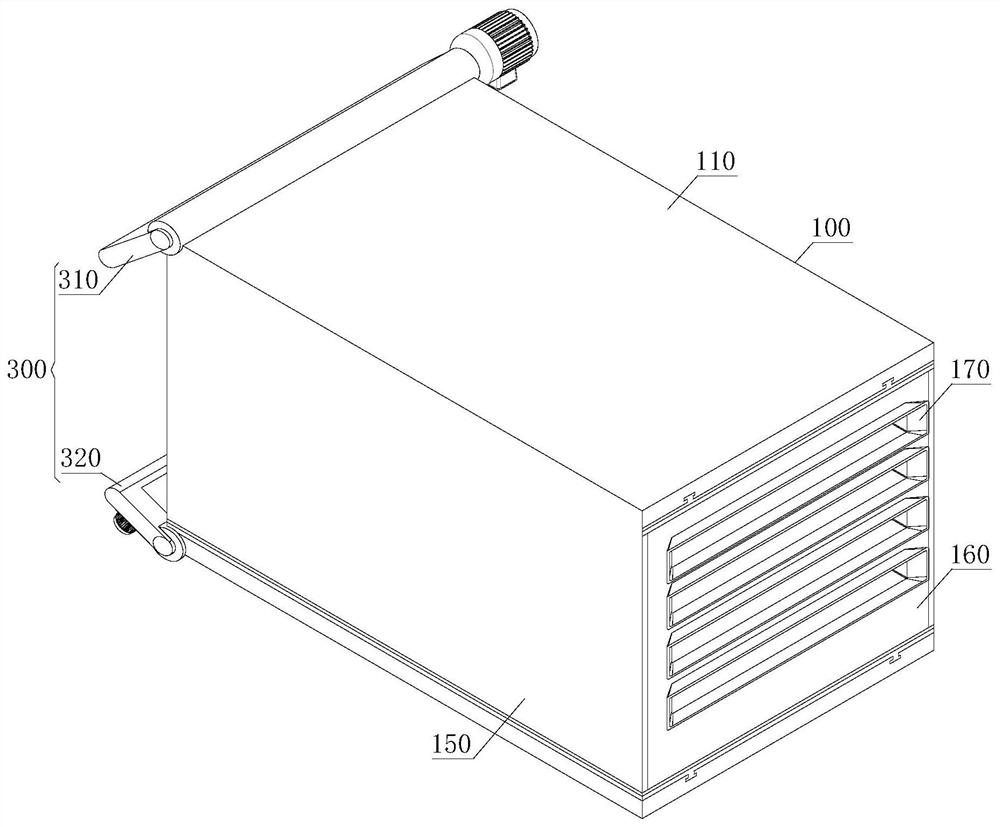

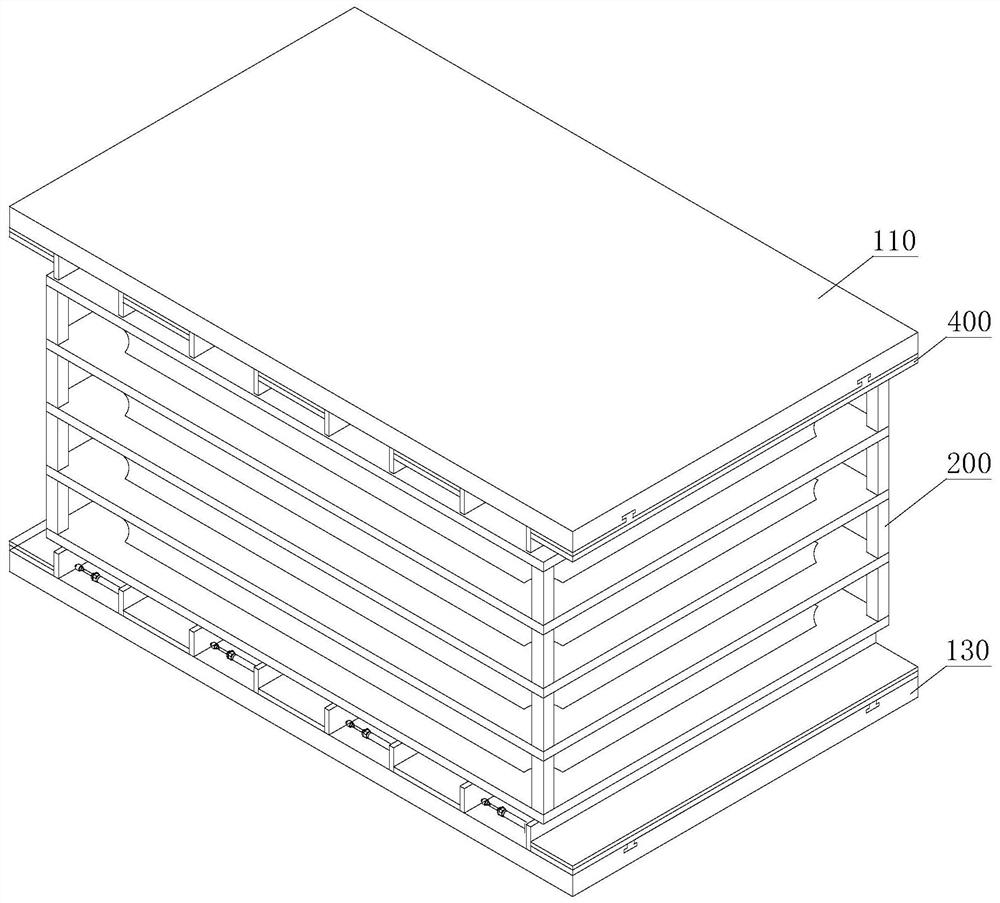

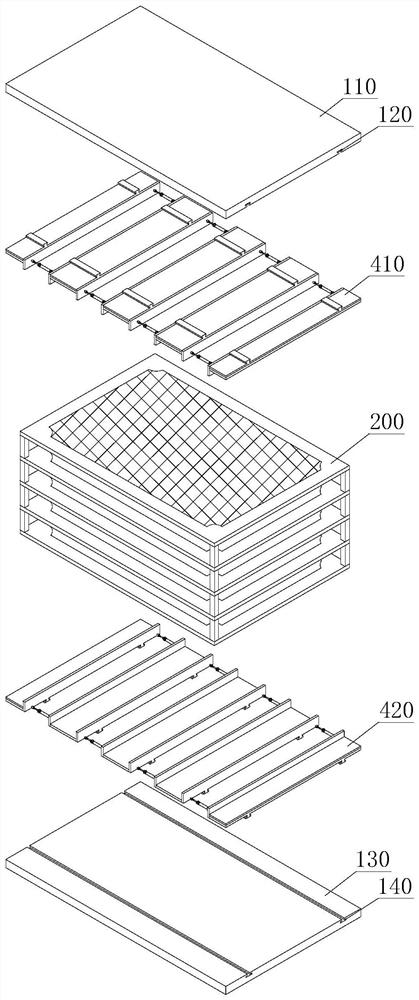

[0039] refer to Figure 1 to Figure 3, a drying equipment with a three-dimensional floating function, comprising a drying box 100, a drying core 200, a feed opening position control device 300 and a floating device 400, the left end of the drying box 100 is provided with a feed opening position control device 300, and the drying box Inside the 100 are installed a floating device 400 and a drying core 200 .

[0040] The drying box 100 includes a top plate 110, a top plate chute 120, a bottom plate 130, a bottom plate chute 140, a side plate 150, a rear end plate 160 and a discharge port 170, and two mutually parallel top plate chutes are provided on the lower bottom surface of the top plate 110. 120, the upper surface of the bottom plate 130 is provided with two parallel bottom plate chutes 140, the top plate 110 and the bottom plate 130 are fixedly connected by two parallel side plates 150, and the left end of the drying box 100 is an open feeding port , the right end is prov...

Embodiment approach

[0047] refer to Figure 10 , in order to better demonstrate the implementation process of the drying equipment with the three-dimensional floating function, this embodiment now proposes an implementation method of the drying equipment with the three-dimensional floating function, including the following steps:

[0048] S101: Forming a magnetic field, electrifying the magnetic plates 415, forming a magnetic field between two overlapping magnetic plates 415 in the vertical direction, and forming a gravity field between two adjacent magnetic plates 415 overlapping in the horizontal direction; 412 telescopic length, adjust the width of the magnetic field and gravity field in the horizontal direction

[0049] S102: initial speed, the driving motor 314 drives the fan 311 to rotate, sucks the material to be dried into the drying box 100, and at the same time gives the material to be dried an initial speed; the rotating shaft 330 can be driven to rotate by the rotating motor 340, and ...

Embodiment 2

[0052] refer to Figure 8 , a drying equipment with a three-dimensional floating function, comprising a drying box 100, a drying core 200, a feed opening position control device 300 and a floating device 400, the left end of the drying box 100 is provided with a feed opening position control device 300, and the drying box Inside the 100 are installed a floating device 400 and a drying core 200 .

[0053] The drying box 100 includes a top plate 110, a top plate chute 120, a bottom plate 130, a bottom plate chute 140, a side plate 150, a rear end plate 160 and a discharge port 170, and two mutually parallel top plate chutes are provided on the lower bottom surface of the top plate 110. 120, the upper surface of the bottom plate 130 is provided with two parallel bottom plate chutes 140, the top plate 110 and the bottom plate 130 are fixedly connected by two parallel side plates 150, and the left end of the drying box 100 is an open feeding port , the right end is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com