Portable pressure pipeline welding seam digital X-ray detection remote control positioning device

A technology for pressure pipelines and remote control, applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as difficulty in improving efficiency, high labor intensity, and non-portability, and achieve size reduction, efficiency improvement, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] Preferred embodiments of the present invention are:

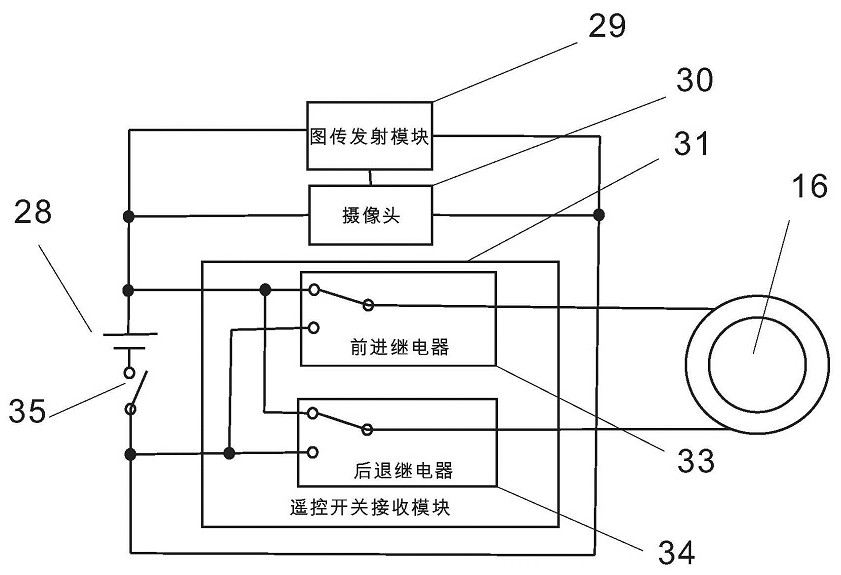

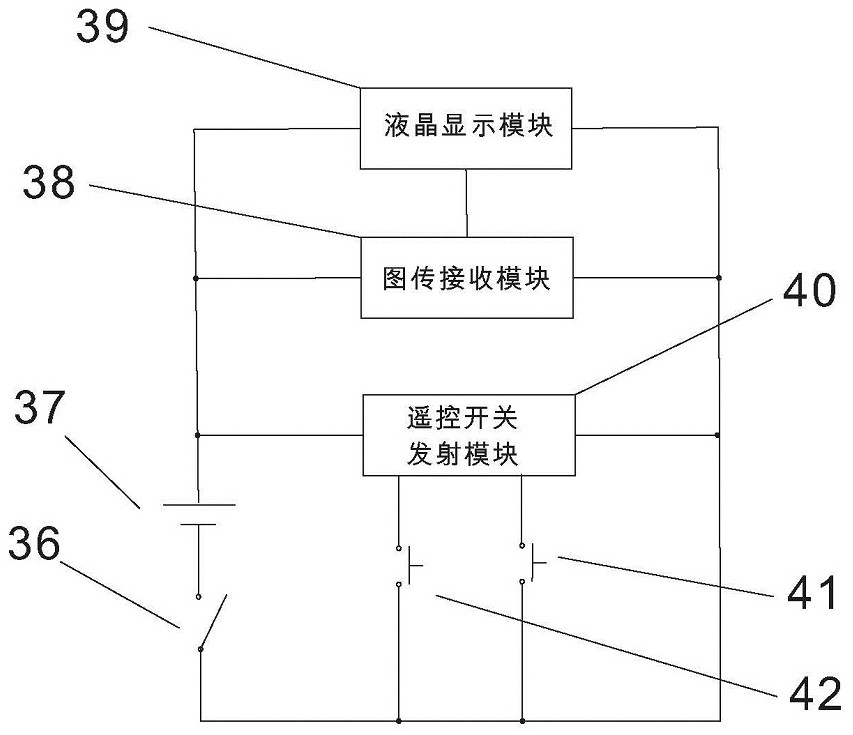

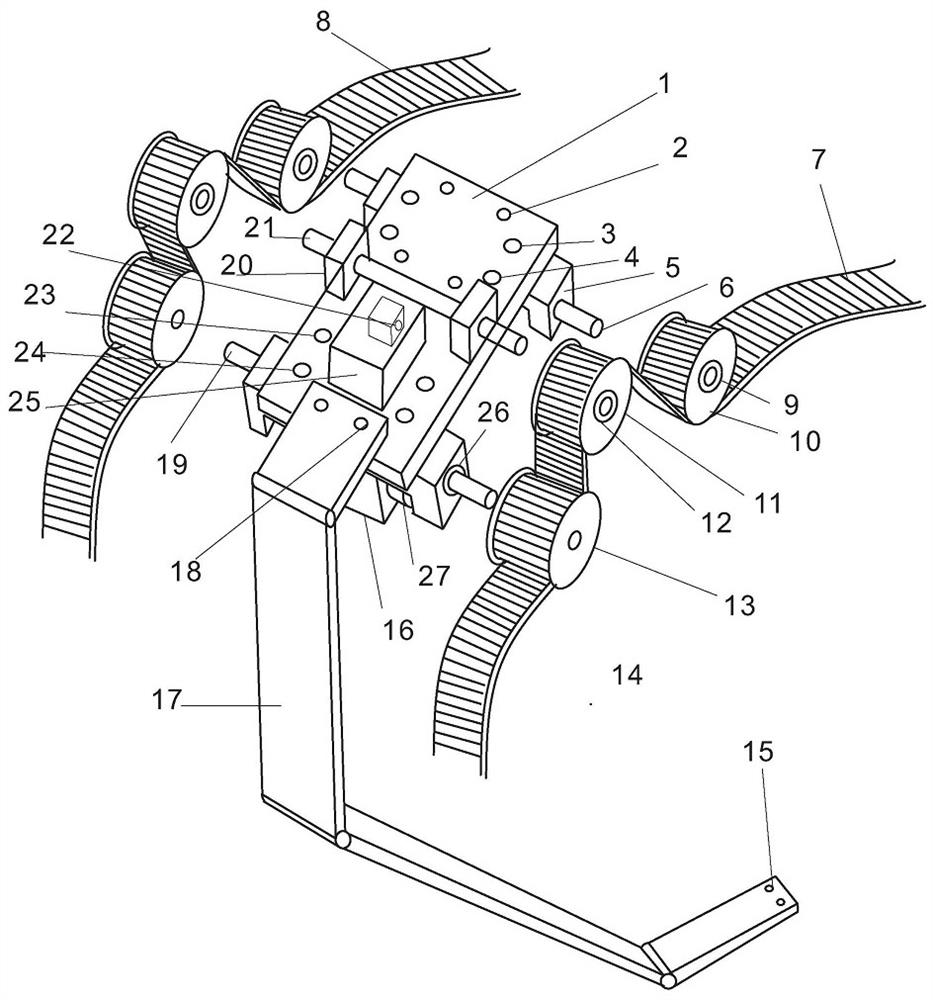

[0020] Such as figure 1 As shown, the remote control and positioning device for digital X-ray detection of portable pressure pipe welds includes: a timing belt 8, consisting of a trolley frame 1, a drive bracket 14, a drive reduction motor 16, a coupling 27, a drive shaft 19, a drive bearing 26, Driving wheel 13, driven bracket 5, driven shaft 6, driven wheel bearing 9, driven wheel 10, tensioning bracket 20, tensioning shaft 21, tensioning wheel bearing 12, tensioning wheel 11 Composed of positioning trolley, flexible arm 17. The trolley control unit is composed of electrical box 25, 12V lithium battery 28, main power switch 35, remote control switch receiving module 31, driving deceleration motor 16, camera 30, and image transmission module 29. It is composed of terminal 12V lithium battery 37, terminal A control terminal composed of a main power switch 36 , an image transmission receiving module 38 , a liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com