Size measurement scoring device, adjusting method and scoring method

A size and detection platform technology, applied in the field of image recognition, can solve the problems of human error, time-consuming, and error-prone in measurement readings, and achieve the effect of consistent image magnification, avoiding system errors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

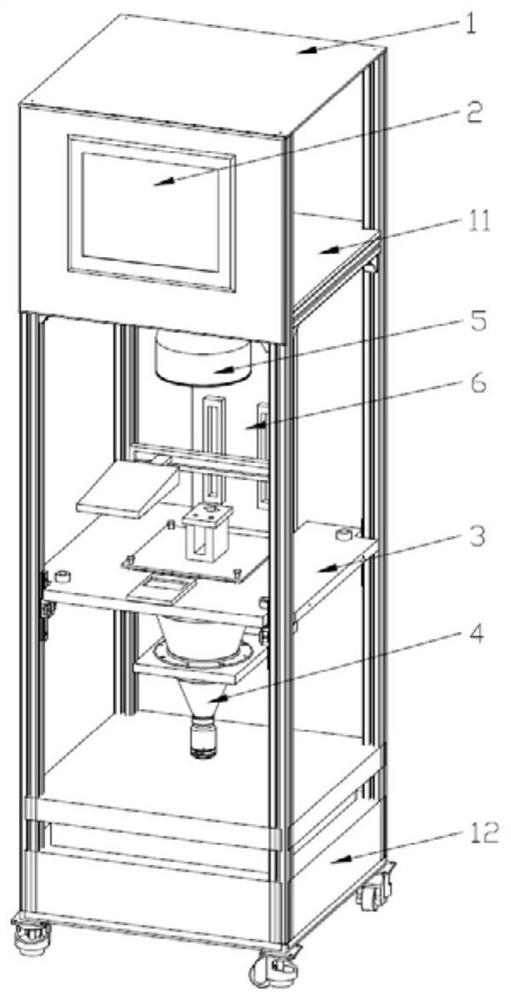

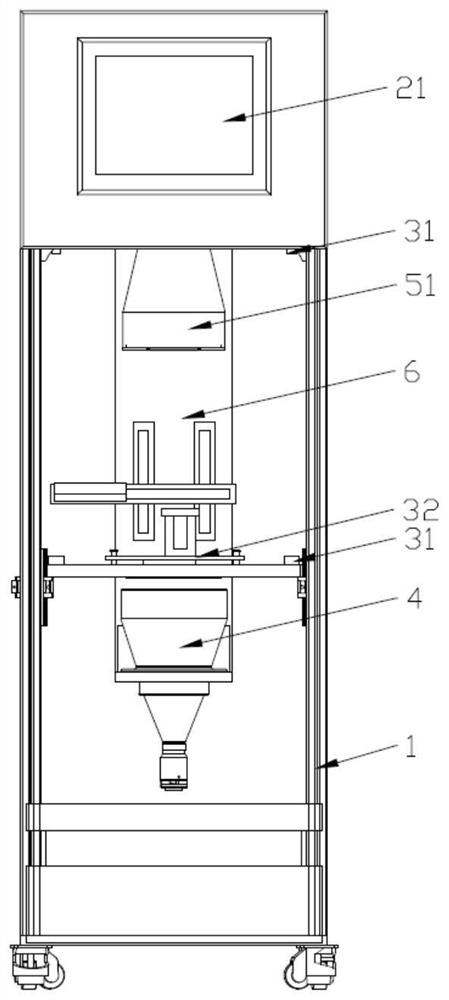

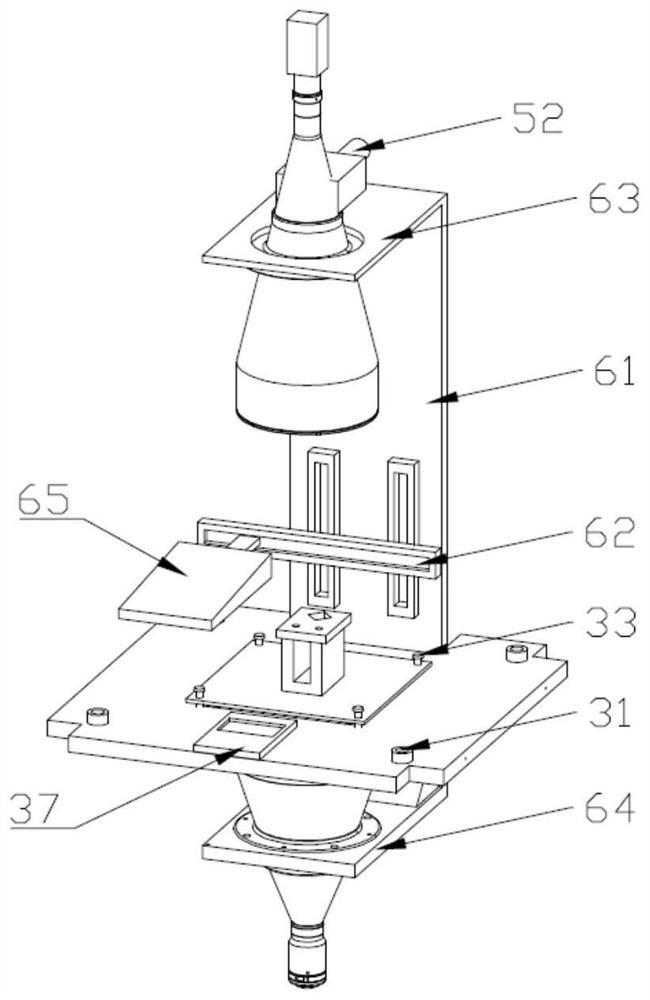

[0063] Such as figure 1 As shown, an adjustable size measuring instrument based on machine vision includes an operating platform 2 , a testing platform 3 , a light source 4 and a camera 5 . The middle part of the detection table 3 is provided with a through hole, and an object carrier 32 is arranged at the through hole, and the object carrier 32 is a transparent material; the light source 4 is arranged below the object carrier 32, and is correspondingly arranged with the object carrier 32; The camera 5 is arranged directly above the object plate 32 , and the camera 5 is located on the camera fixing plate 11 ;

[0064] Such as figure 2 As shown, the detection table 3, the light source 4 and the camera 5 are arranged on the fixed frame 1. The fixed frame 1 is in the shape of a straight square prism as a whole, and the interior is hollow. The fixed frame is arranged above the optical vibration isolation table 12. Platform 12 lowers the center of gravity to achieve the purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com