Multi-specification conductive assembly manufacturing device

A technology for conducting components and manufacturing devices, which is applied in the manufacturing of electrical components, emergency protection devices, emergency protection devices, etc., can solve problems such as low production efficiency and incompatibility with conductive components, and achieve efficiency improvement, long-distance positioning, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] Taking the conventional electromagnetic coil assembly as an example, the present invention can also realize the automatic assembly of parts of the electromagnetic coil assembly with different specifications in the same way.

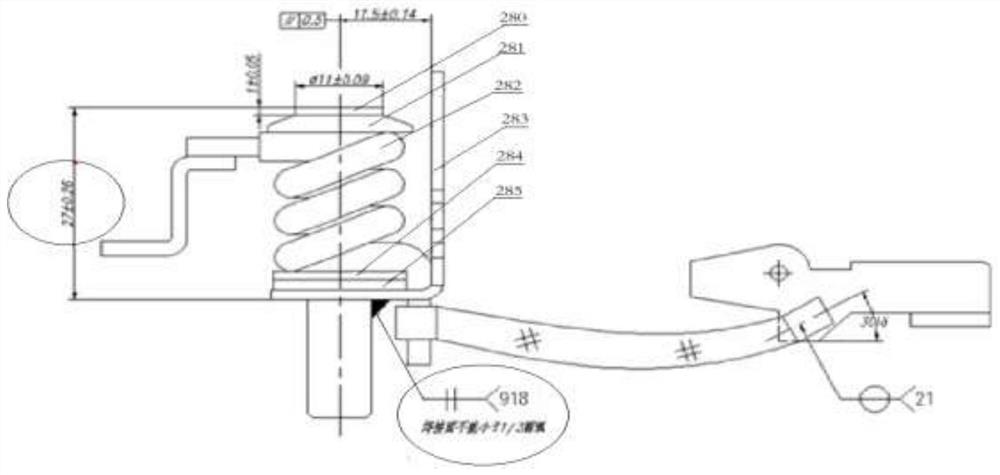

[0041] Such as figure 1 As shown, the electromagnetic coil assembly includes a T-shaped electro-hydraulic magnetic cup 280, and the T-shaped electro-hydraulic magnetic cup 280 is equipped with insulating gaskets 281 corresponding to different sizes, a soft assembly 282, an upper insulating gasket 284 and an upper The insulating spacer 285 and the magnetic yoke 283 are fixedly connected with the T-shaped electro-hydraulic magnetic cup 280 by tin welding the magnetic yoke 283 and the T-shaped electro-hydraulic magnetic cup 280 after assembly.

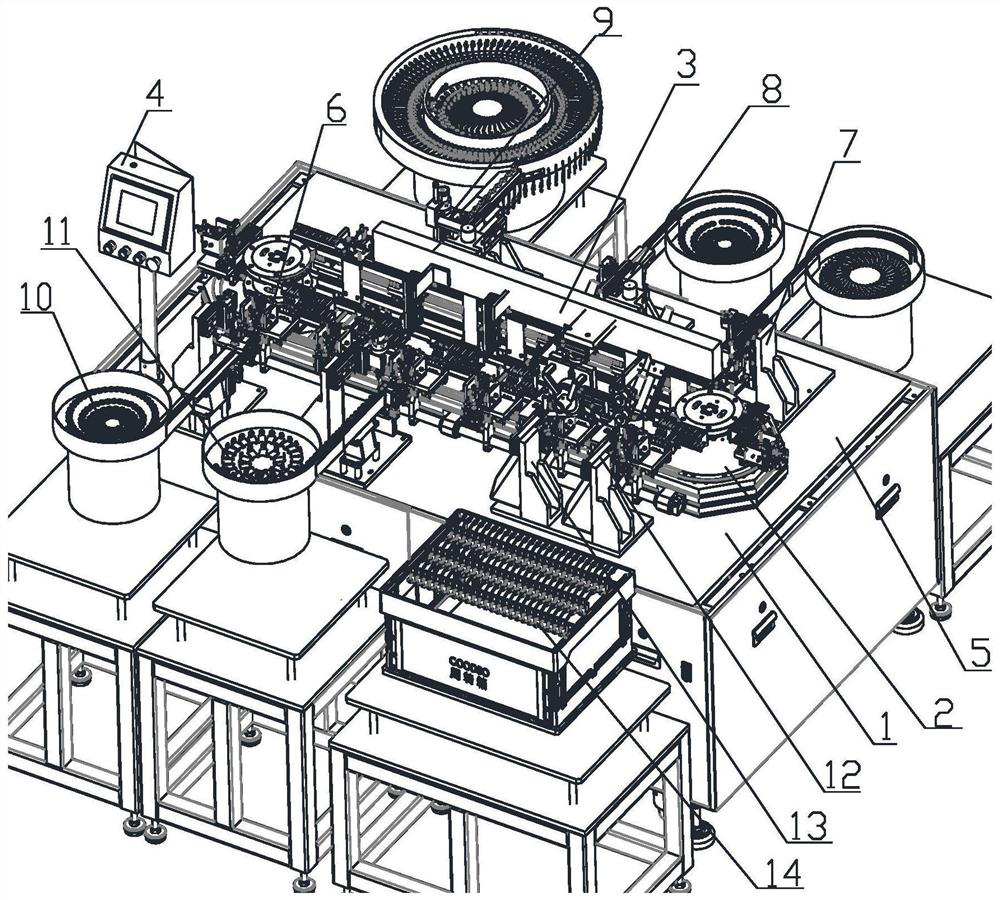

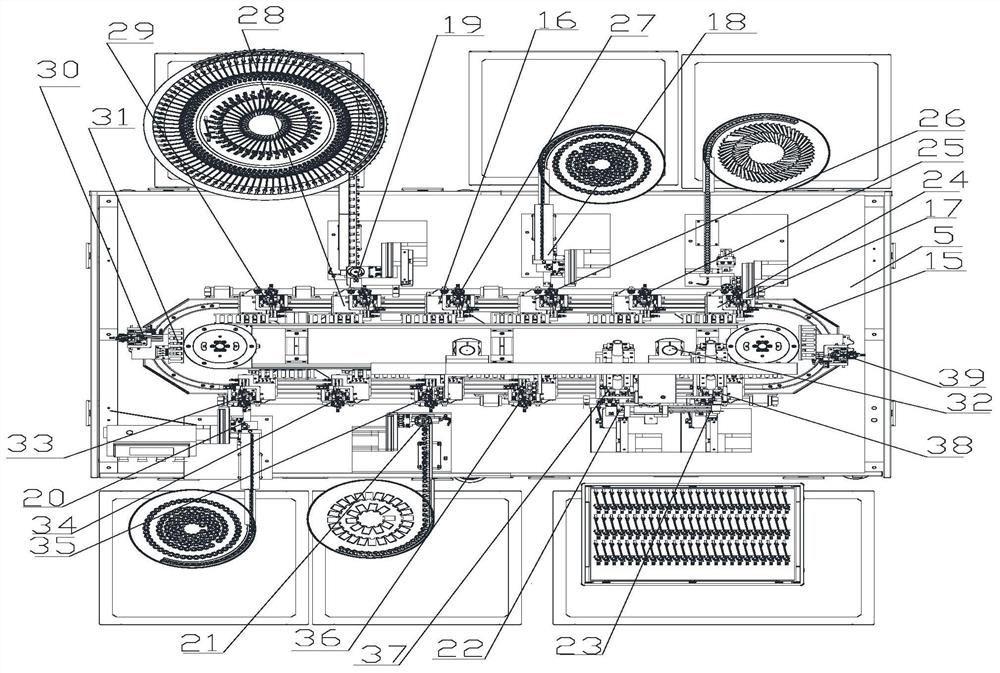

[0042] The present invention is a multi-standard conductive component man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com