Slitting equipment for battery steel shell machining

A battery steel shell and equipment technology, applied in the field of cutting equipment for battery steel shell processing, can solve the problems of troublesome cutting, inability to guarantee the stability of the steel shell during cutting, inconvenient use, etc., and achieve convenient use and unified processing and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

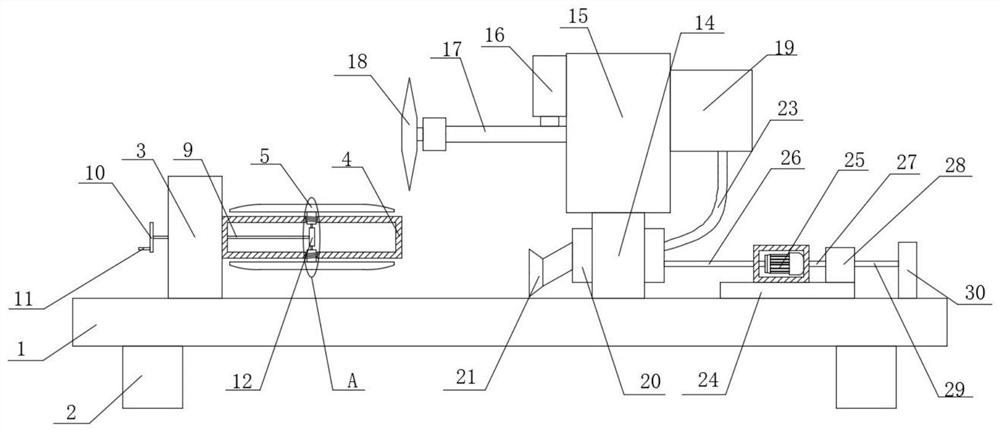

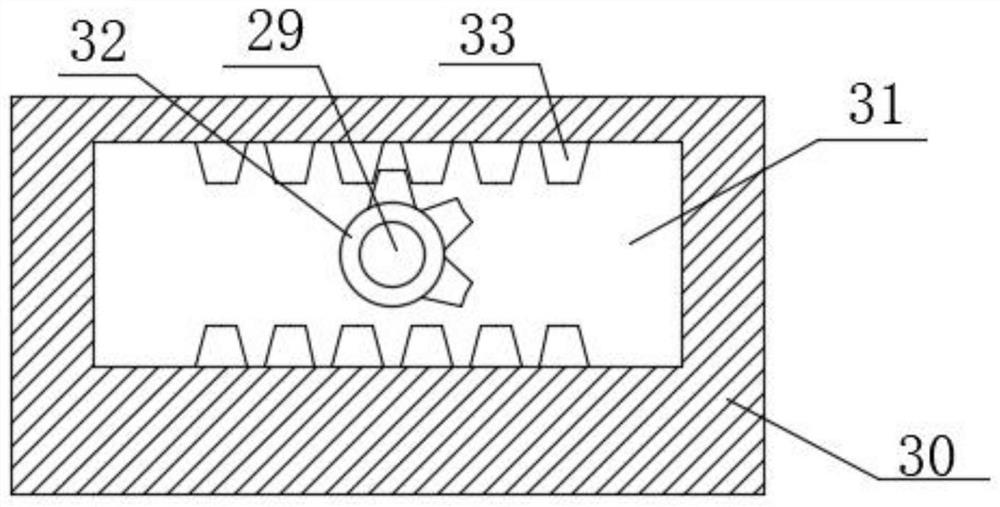

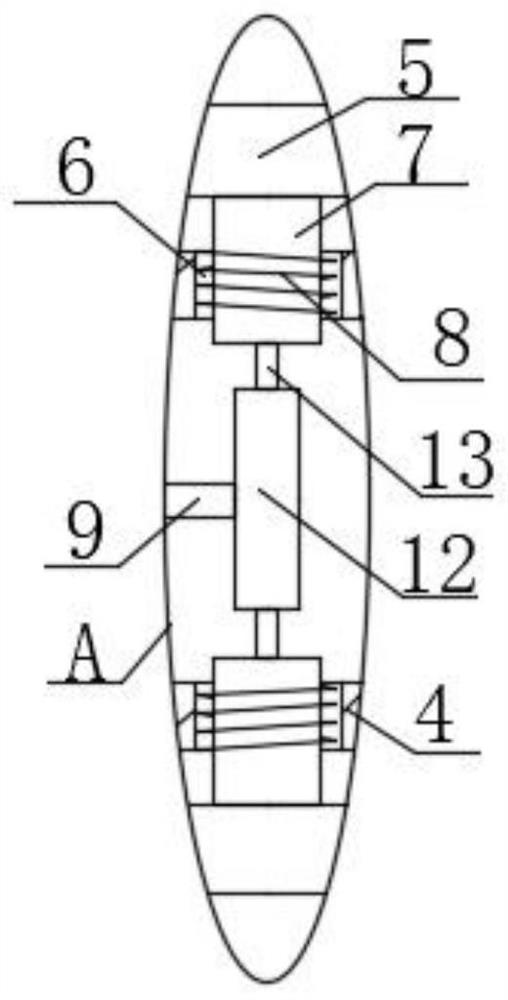

[0026] refer to Figure 1-5 , a cutting device for battery steel case processing, comprising a base plate 1, two brackets 2 are symmetrically fixedly mounted on the bottom of the base plate 1, a mounting plate 3 is fixedly mounted on the top of the base plate 1, and a mounting plate 3 is fixedly mounted on one side of the mounting plate 3. Tube 4, two stabilizing plates 5 are installed symmetrically slidingly on the placement tube 4, a rotating rod 9 is installed on the placement tube 4, and a circular plate 10 is fixedly installed on one end of the rotating rod 9, and a handle is fixedly installed on one side of the circular plate 10 11. The rotating rod 9 cooperates with the two stabilizing plates 5, and the top of the bottom plate 1 is symmetrically fixed with two support plates 14, and the top of the two support plates 14 is fixedly installed with the same top plate 15, and one side of the top plate 15 is fixedly installed There is an electric push rod 16, a fixed plate 17...

Embodiment 2

[0035] refer to Figure 1-5, a kind of cutting equipment for battery steel shell processing, comprising a base plate 1, the bottom of the base plate 1 is symmetrically fixed with two brackets 2 by welding, the top of the base plate 1 is fixedly installed with a mounting plate 3 by welding, and one side of the mounting plate 3 A placement tube 4 is fixedly installed by welding, and two stabilizing plates 5 are installed on the placement tube 4 for symmetrical sliding, and a rotating rod 9 is installed on the placement tube 4, and a circular plate 10 is fixedly installed on one end of the rotating rod 9 by welding. One side of 10 is fixedly equipped with a handle 11 by welding, the rotating rod 9 is matched with two stabilizing plates 5, and the top of the bottom plate 1 is symmetrically fixed with two support plates 14 by welding, and the tops of the two support plates 14 are fixed by welding The same top plate 15 is installed, and one side of the top plate 15 is fixed with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com