Chemical mechanical polishing method and device

A technology of chemical machinery and polishing devices, which is applied in the direction of grinding devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems affecting the effect of fine polishing and cleaning, and achieve the effect of reducing particle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

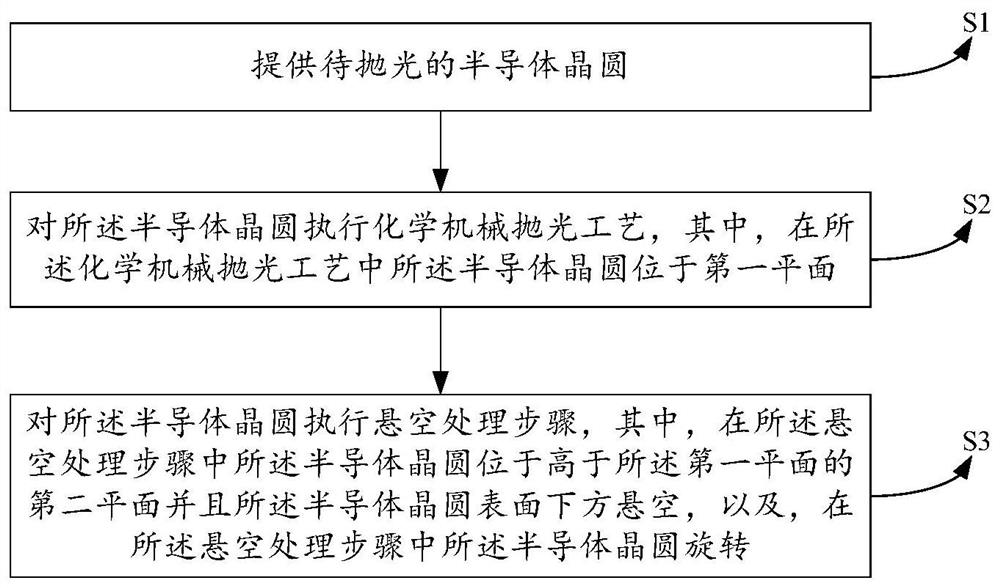

[0039] In order to solve the problems in the prior art, the invention provides a chemical mechanical polishing method, comprising:

[0040] Provide semiconductor wafers to be polished;

[0041] performing a chemical mechanical polishing process on the semiconductor wafer, wherein the semiconductor wafer is located on a first plane during the chemical mechanical polishing process;

[0042] performing a floating processing step on the semiconductor wafer, wherein in the floating processing step the semiconductor wafer is located at a second plane higher than the first plane and is suspended below a surface of the semiconductor wafer, and wherein, The semiconductor wafer is rotated in the floating processing step.

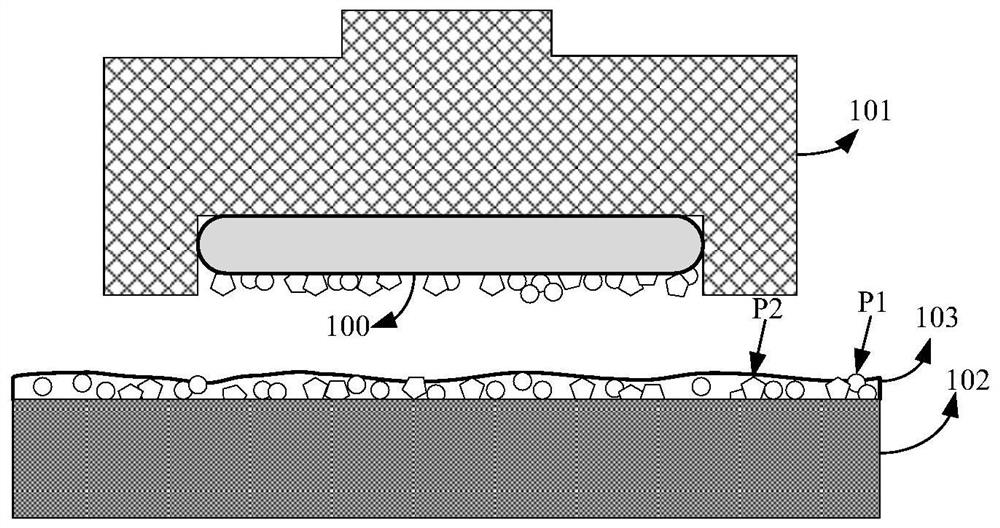

[0043] see below figure 2 and Figure 3A-Figure 3C A chemical mechanical polishing method according to the present invention is exemplified. in, figure 2 It is a schematic flow chart of a chemical mechanical polishing method according to an embodiment of the pr...

Embodiment 2

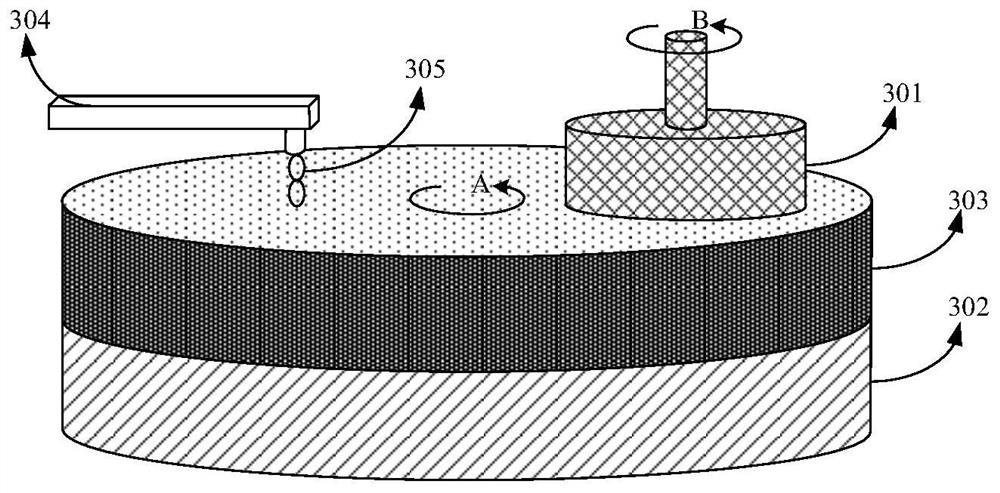

[0077] The present invention also provides a chemical mechanical polishing device, comprising:

[0078] The movement of the semiconductor wafer driven by the polishing head includes a first movement and a second movement,

[0079] Under the first movement, a chemical mechanical polishing process is performed, wherein the polishing head is located on a first plane during the chemical mechanical polishing process;

[0080] Under the second movement, a floating processing step is performed, wherein in the floating processing step, the polishing head is located at a second plane higher than the first plane and the semiconductor crystal held by the polishing head is The circle is suspended below, and wherein the polishing head is rotated during the suspension processing step.

[0081] see Figure 3A-Figure 3C An example of a chemical mechanical polishing device according to the present invention is described.

[0082] Such as Figure 3A As shown, the chemical mechanical polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com