A whistle-type continuous acid-flooding washing method suitable for explosives

A washing method, air-whistle technology, applied in the field of acid-displacement washing, air-whistle-type continuous acid-displacement washing, can solve the problems of large amount of washing water, discontinuous operation, low efficiency, etc., and achieve reduced consumption and high operability Strong, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

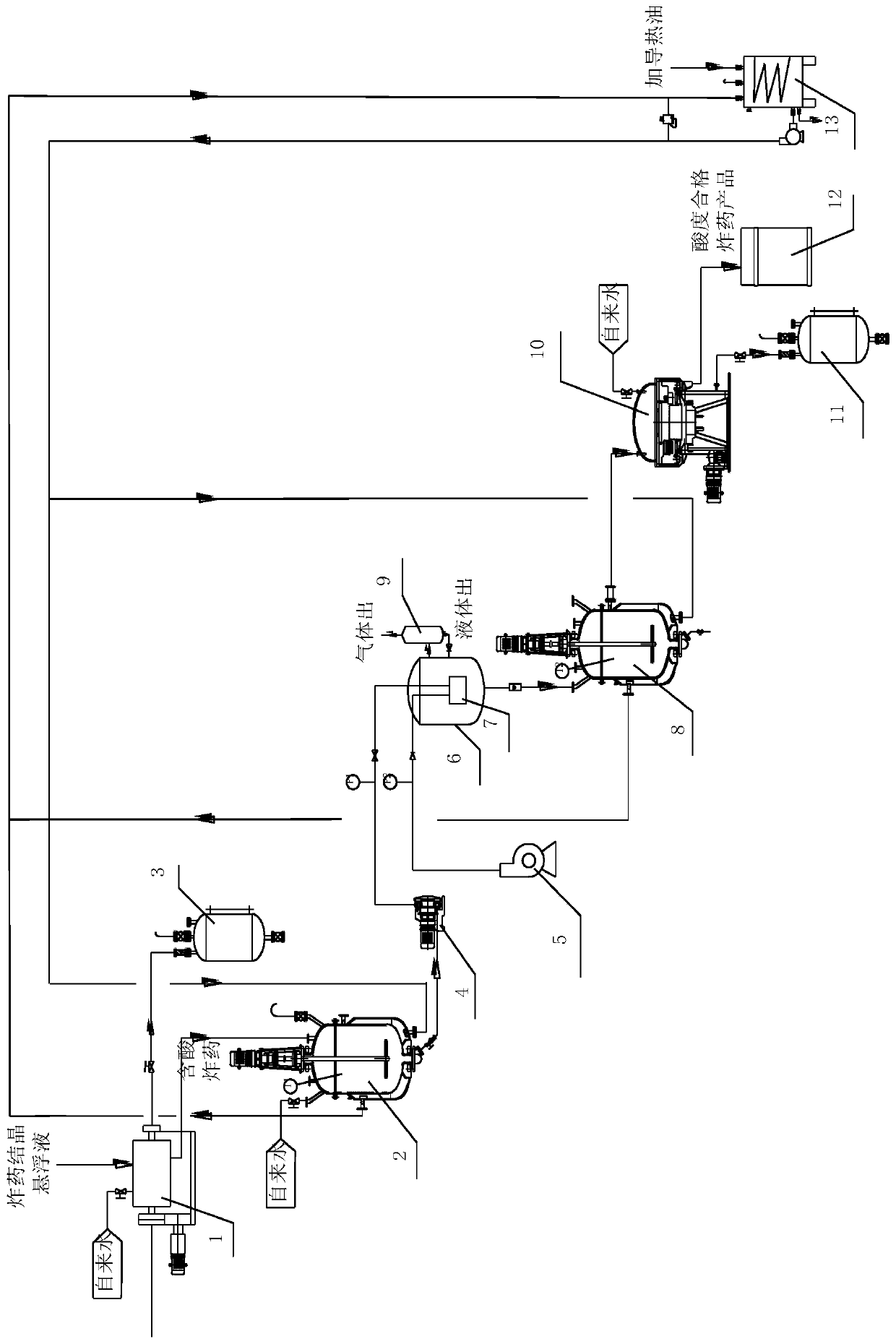

[0028] The present embodiment carries out as follows:

[0029] (1) The RDX suspension from the nitration synthesis crystallization process enters the vacuum drum filter 1 with a rotating speed of 1.0rpm through the pipeline, and realizes the separation of RDX and the mother liquor under the action of a vacuum of 0.08MPa, and the mother liquor enters the mother liquor receiving tank 3 , the 5g filter cake TATB of filtering gained enters the 25L first stirring washing kettle 2 that connects through feeding channel, and the first stirring washing kettle 2 adds 18L washing water through pipeline, is that 80rpm mechanical agitation is carried out once washing at rotating speed, washing temperature Adjust and control the heat transfer at 55°C through the circulation flow heat transfer of the constant temperature heat transfer oil in the jacket of the washing kettle in the high and low temperature integrated machine (13);

[0030] (2) After stirring and washing once, open the meterin...

Embodiment 2

[0034] The present embodiment carries out as follows:

[0035](1) The TATB suspension from the nitration synthesis crystallization process enters the vacuum drum filter 1 with a rotating speed of 1.2rpm through the pipeline, and realizes the separation of TATB and the mother liquor under the action of a vacuum of 0.07MPa, and the mother liquor enters the mother liquor receiving tank 3 , the 6g filter cake TATB of filtering gained enters the 25L first stirring washing kettle 2 that connects through feeding channel, and the first stirring washing kettle 2 adds the washing water of 20L through pipeline, is that 70rpm mechanical agitation is carried out once washing at rotating speed, washing The temperature is adjusted and controlled at 60°C through the heat transfer of the constant temperature heat transfer oil in the high and low temperature integrated machine 13 in the jacket of the washing kettle;

[0036] (2) After stirring and washing once, open the metering diaphragm pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com