A thermal insulation product based on fused deposition modeling and its preparation method

A technology for connecting parts and external parts, applied in the field of additive manufacturing, can solve the problems of poor heat resistance, low service temperature, single resin selection, etc., and achieve the effect of achieving anisotropy and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

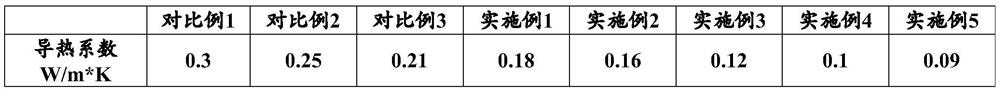

Examples

preparation example Construction

[0084] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0085] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0086] In the description of the present invention, it should be noted that the terms "first", "second", "third", "fourth", "fifth" and so on are only used for descriptive purposes, not to indicate or imply relative importance.

[0087]The grade o...

Embodiment 1

[0109] PC and hollow glass microspheres were blended at a mass ratio of 25:1 for 5 minutes, kneaded and plasticized by a twin-screw extruder, and then prepared into filaments with a diameter of 1.75 mm by a single-screw extruder. The processing temperature range of twin-screw extruder and single-screw extruder is 270-300°C. According to ISO1133, under the test condition of 300°C and 1.2kg, the measured melt index is 28g / 10min.

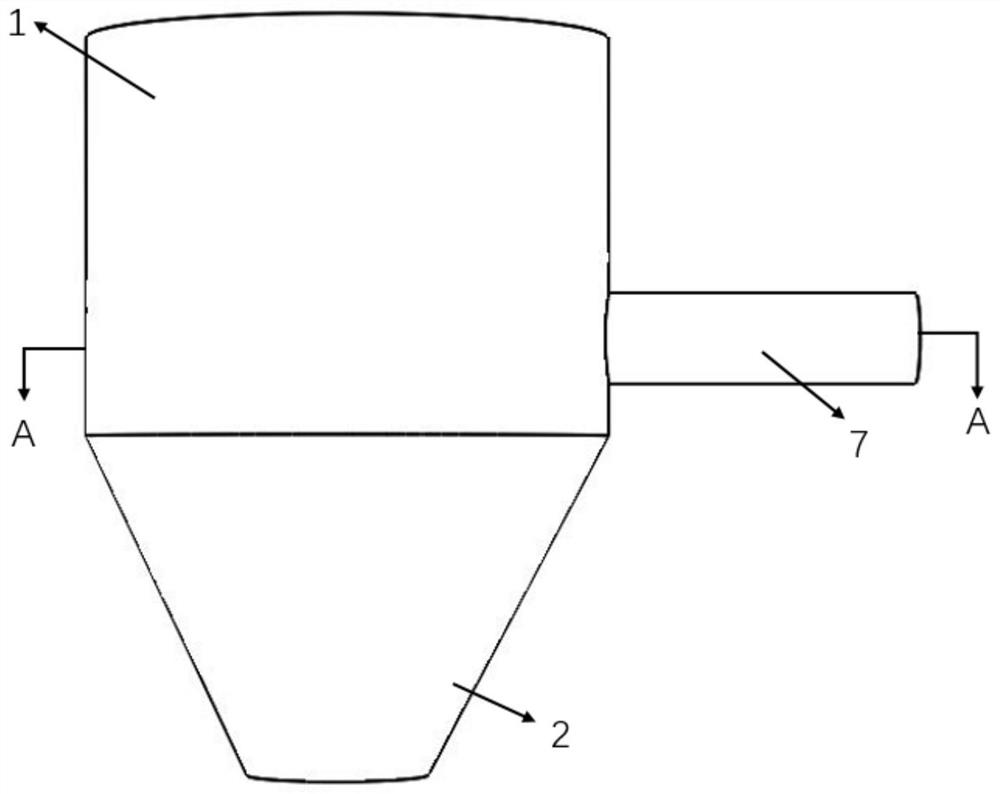

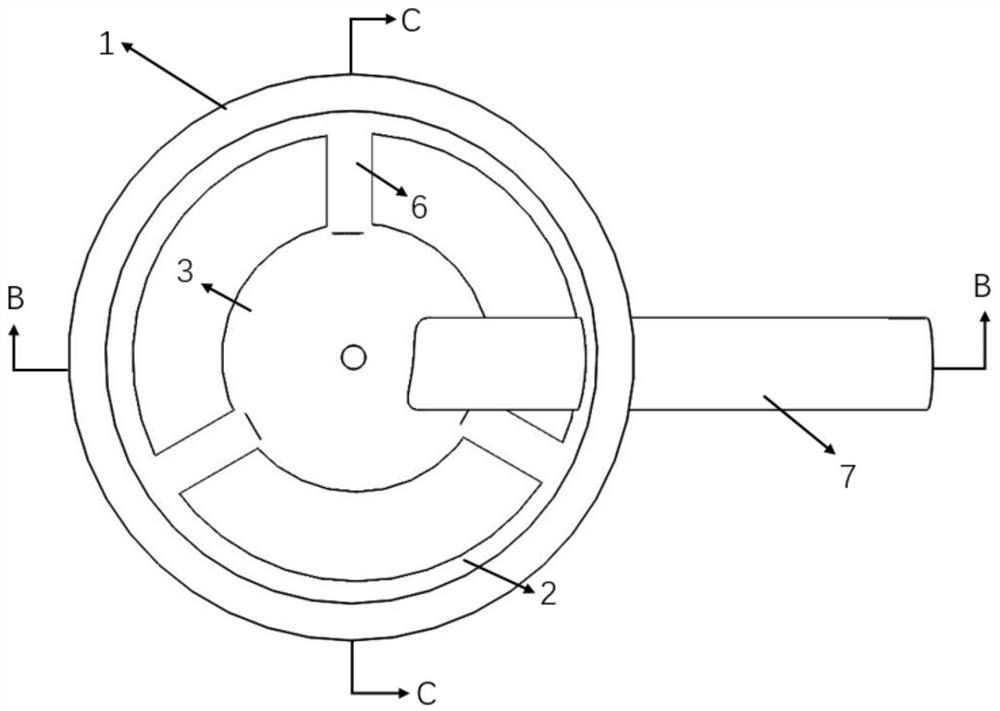

[0110] With the above-mentioned filaments as the first component material, FDM 3D printing is carried out by using the two-component feeding nozzle designed by the present invention, and polyethylene wax is introduced as the second component material at the same time. The outer nozzle diameter of the nozzle is 0.6mm, and the inner nozzle diameter is 0.4mm. The temperature of the external heating container is controlled at 120°C, so that the dynamic viscosity of the polyethylene wax is about 30mPa*s. By applying external pressure, the mass ratio of th...

Embodiment 2

[0113] Others are the same as in Example 1, the only difference is that the mass ratio of the first component material and the second component material is controlled at 10:1 by applying external pressure.

[0114] The printing parameter settings are the same as those in Comparative Example 1. Prepare a disc with a diameter of 30 mm and a thickness of 3 mm for thermal conductivity testing. Prepare a disc with a diameter of 30 mm and a thickness of 3 mm for thermal conductivity testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com