Method for preparing high-purity alpha-Al2O3 powder by calcining aluminum ammonium sulfate at low temperature

A technology of aluminum ammonium sulfate and low-temperature calcination, which is applied in the field of material science, can solve problems affecting application and reducing powder purity, and achieve the effects of reducing energy consumption, simple process, and avoiding the reduction of powder purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

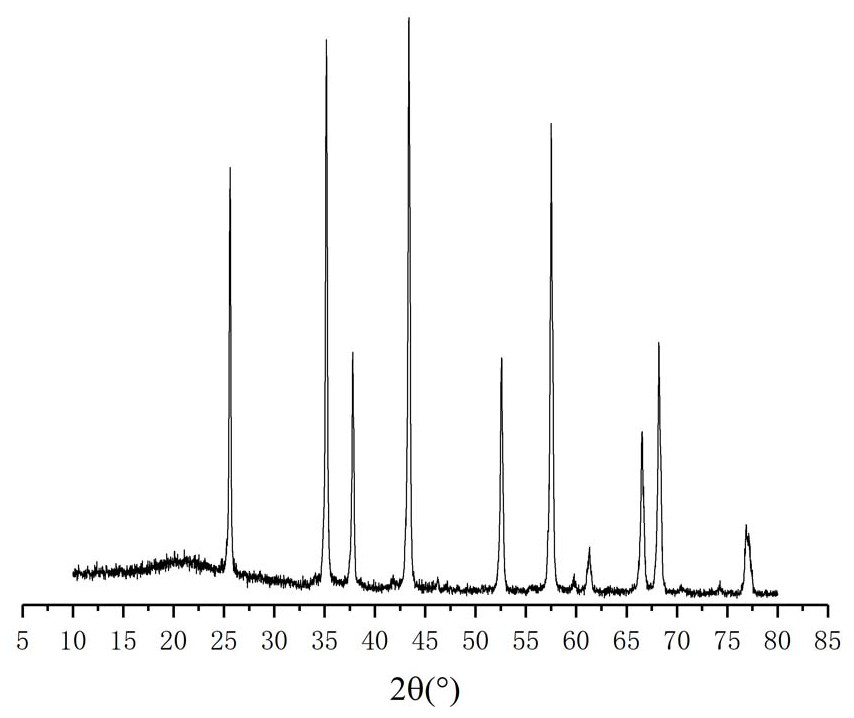

[0012] Example 1: Take 100g of high-purity ammonium aluminum sulfate powder, add 200ml of deionized water, add ammonia water dropwise to adjust pH = 11, put it in an oven at 80°C, cool to room temperature after the ammonium aluminum sulfate is completely dissolved, and crystallize naturally for 2 hours; The crystallized product was fully washed, filtered with suction, and dried in an oven at 50°C for 24 hours. The obtained product was put into a corundum crucible and calcined at 1050°C for 2 hours, and the final powder was obtained after cooling. The XRD analysis of the above powder shows that the obtained powder is pure α-Al 2 o 3 powder, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com