Plasma display panel

A display panel and plasma technology, applied in the direction of AC plasma display panel, gas discharge electrode, cathode ray/electron beam tube shell/container, etc., can solve the problems of longer sealing processing time, high price, and rising cost. Achieve the effects of shortening the processing time, preventing decomposition, and preventing the reduction of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

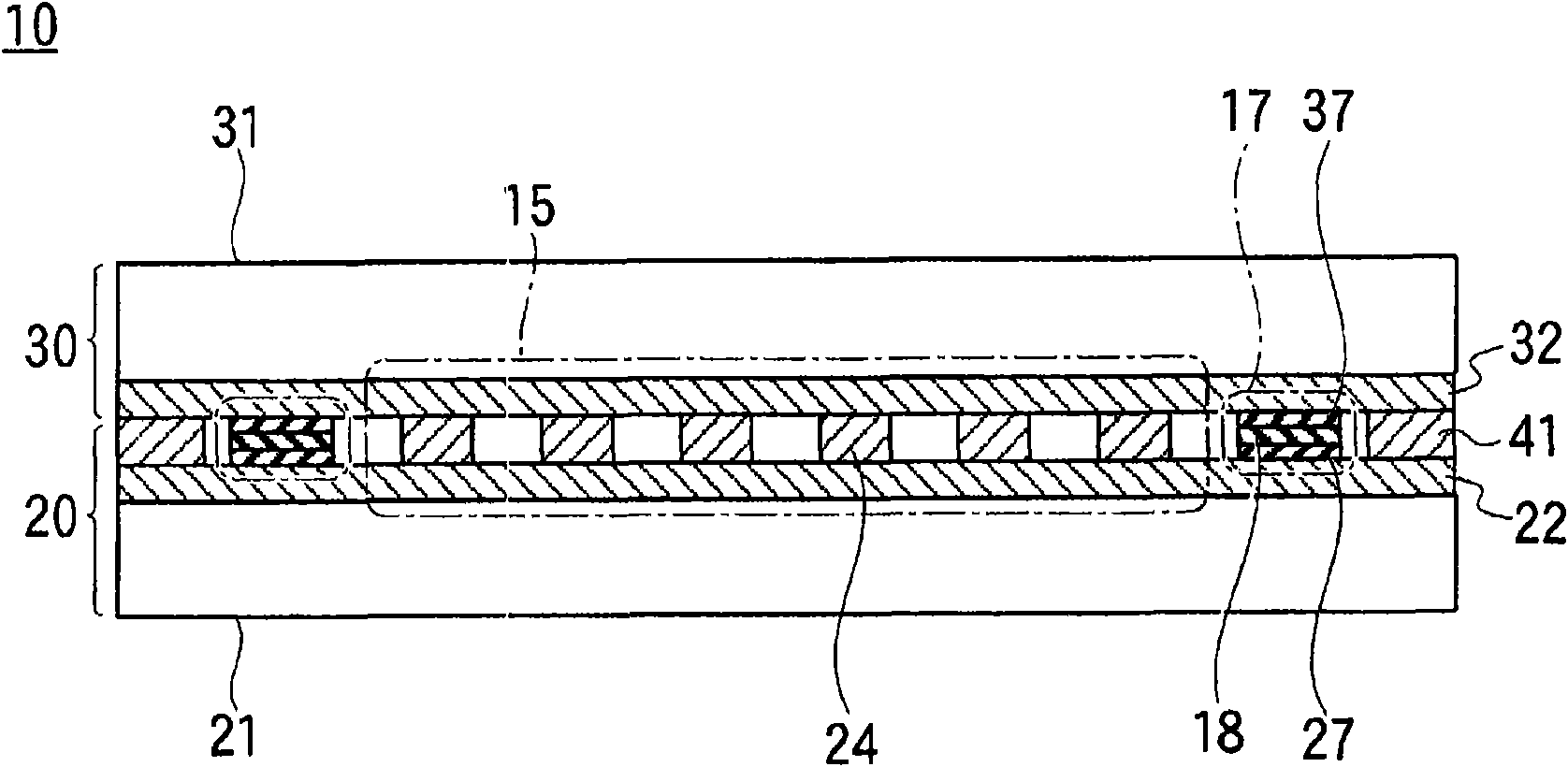

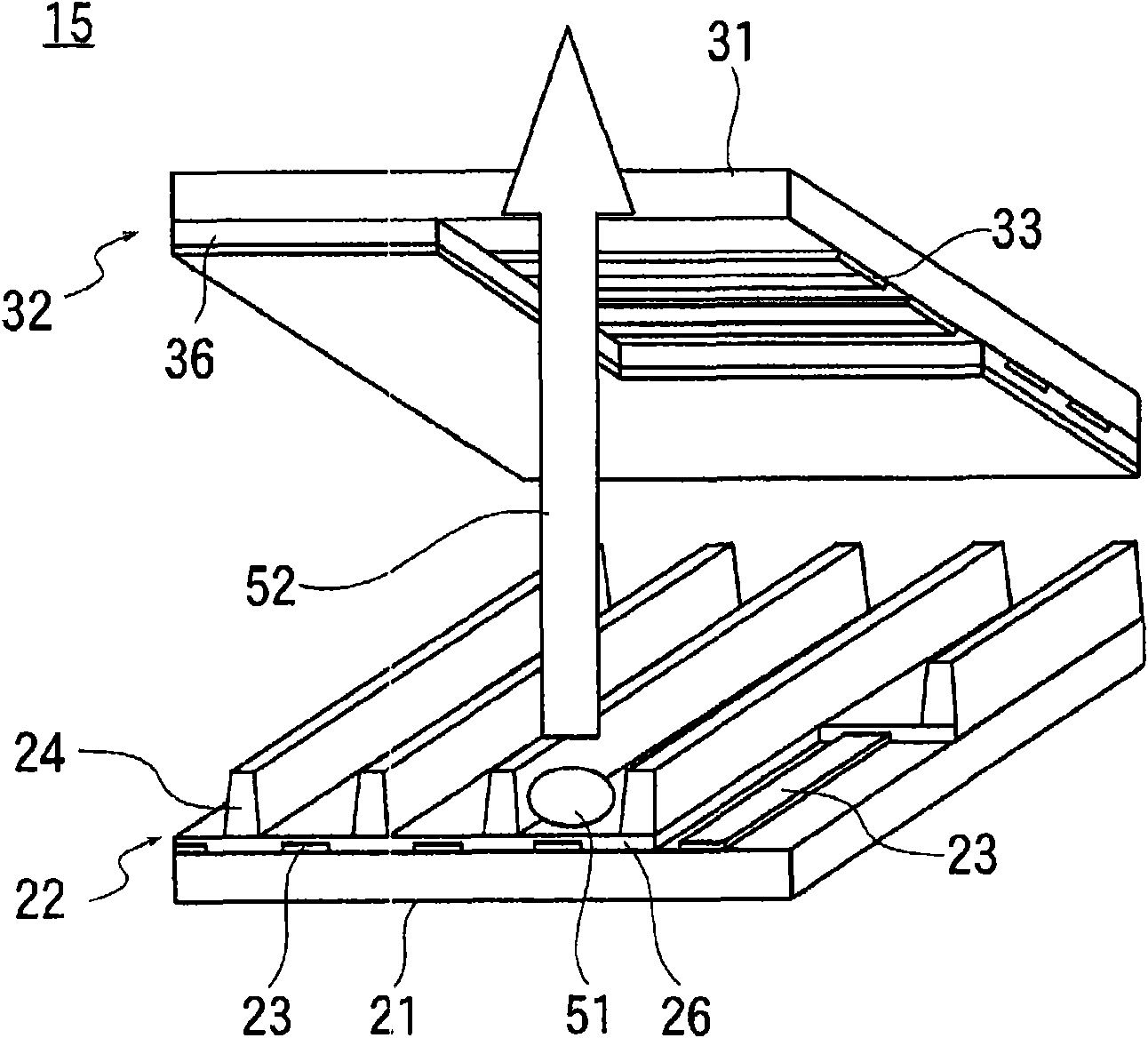

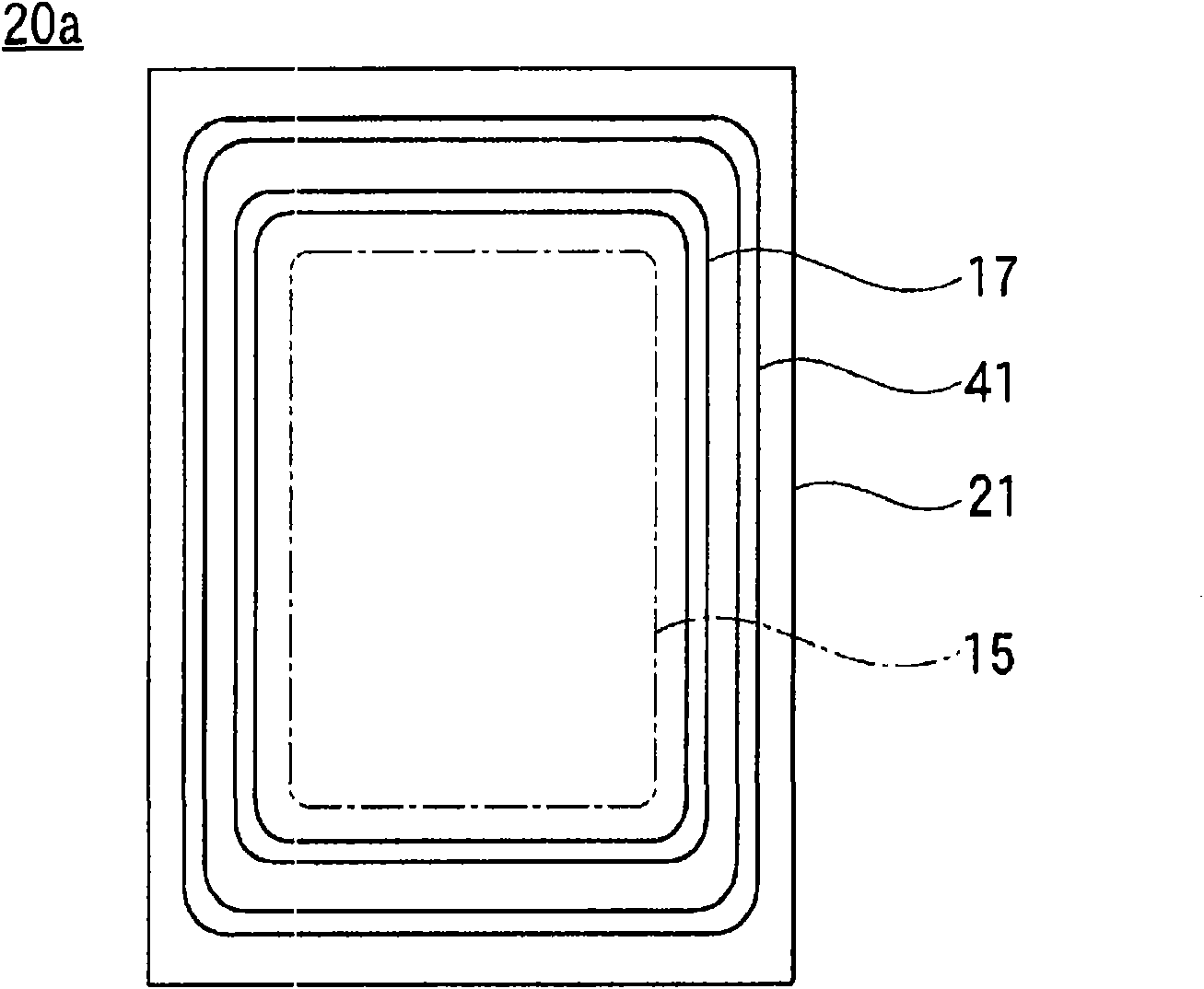

Embodiment 1

[0108] Ne-4% Xe is used as the discharge gas, and it is introduced into the light-emitting area 15 under a pressure of 400 Torr, and the sealed plasma display panel 10 of the present invention is placed in a constant temperature and humidity chamber at 85°C and a humidity of 95%, and Measure the drop change in discharge voltage. exist Figure 6 (a) shows the relationship between the standing time and the discharge voltage.

[0109] For comparison, under the same conditions, the existing plasma display panel 110 ( Figure 11 ) discharge voltage. exist Figure 6 (b) shows the relationship between the standing time and the discharge voltage.

[0110] The final cell lighting voltage is the driving voltage required to start discharging all cells.

[0111] In addition, the first cell light-off voltage is the voltage for the first cell light-off when the driving voltage is gradually decreased from the state where all the cells are turned on.

[0112] In the plasma display panel ...

Embodiment 2

[0116] Next, the plasma display panel 10 of the present invention was placed in a constant temperature and humidity chamber at 50° C. and a humidity of 50%, and placed in a state where a voltage was applied to the electrodes to emit light, and the discharge voltage was measured. Figure 7 (a) shows the relationship between the time for applying a voltage to the electrode (aging time) and the discharge voltage.

[0117] For comparison, under the same conditions, the existing plasma display panel 110 ( Figure 11 ) discharge voltage. Figure 7 (b) shows the relationship between aging time and discharge voltage.

[0118] In the plasma display panel 10 of the present invention, even if the aging time reaches 2000 hours, the voltage rise is 10 V or less. This is because the ultraviolet rays emitted by the plasma are blocked by the sealing portion 17 and do not irradiate the sealing portion 41 , the sealing portion 41 is not decomposed, and the release of impurity gas is prevented....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com