A method for recycling steel fibers in steel fiber reinforced concrete

A reinforced concrete and fiber reinforced technology, which is applied in the field of steel fiber recycling and reuse in steel fiber reinforced concrete, can solve the problems of unsatisfactory failure mode, insufficient utilization of potential mechanical properties of energy dissipative fibers, and reduced toughness of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: The present embodiment records a method of recycling and reusing steel fibers in steel fiber reinforced concrete, the method steps are as follows:

[0026] Step 1: Prepare ordinary concrete or ultra-high-performance concrete: according to the mix ratio of ordinary concrete or ultra-high-performance concrete, on this basis, steel fibers are added, and the dosage is 50-160kg / m 3 At the same time, calcium sulfalinate expander is added, the dosage is 6%-12% of the quality of the cementitious material, and replaces the cementitious material of the same quality; the concrete includes sand, stone aggregate, mineral admixture, water, water reducer; the cementitious material refers to cement;

[0027] Step 2: Recycling of steel fibers in steel fiber reinforced concrete after demolition

[0028] (1) The steel fiber reinforced concrete after service demolition is completely soaked in anhydrous ethanol or isopropanol to prevent the steel fiber from rusting in con...

specific Embodiment approach 2

[0033] Specific embodiment two: a method of recycling and reusing steel fibers in steel fiber reinforced concrete described in specific embodiment I, in step one, the steel fibers are straight, end hook or wavy. Diameter 0.20mm, length 13mm, tensile strength 2850MPa, or other sizes and tensile strength.

Embodiment 1

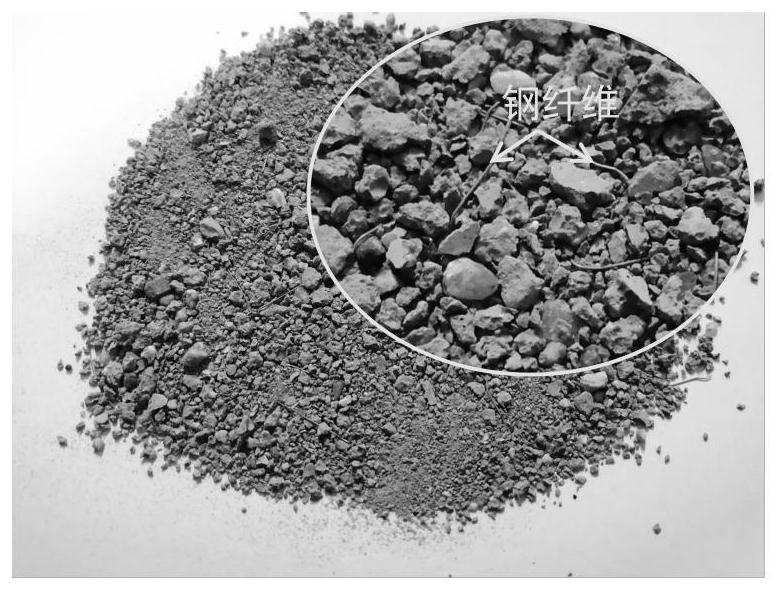

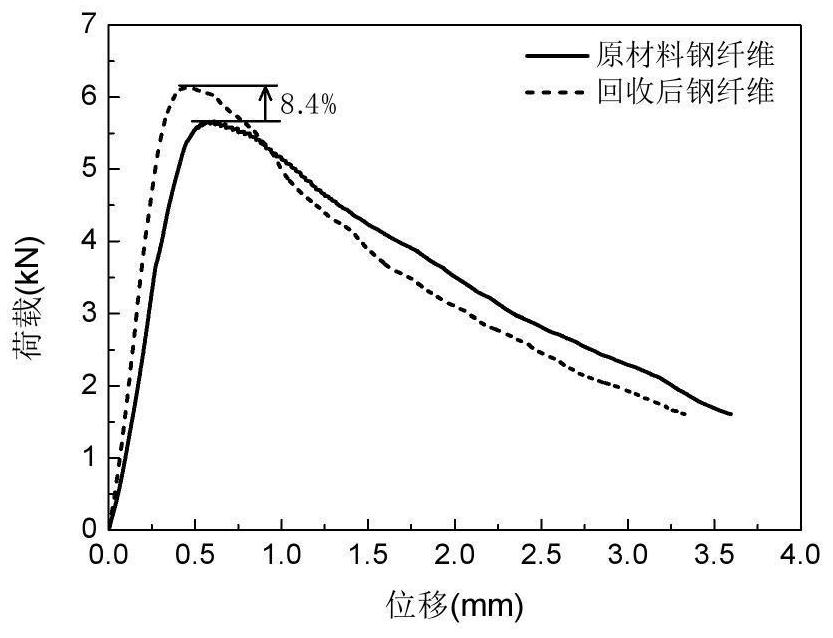

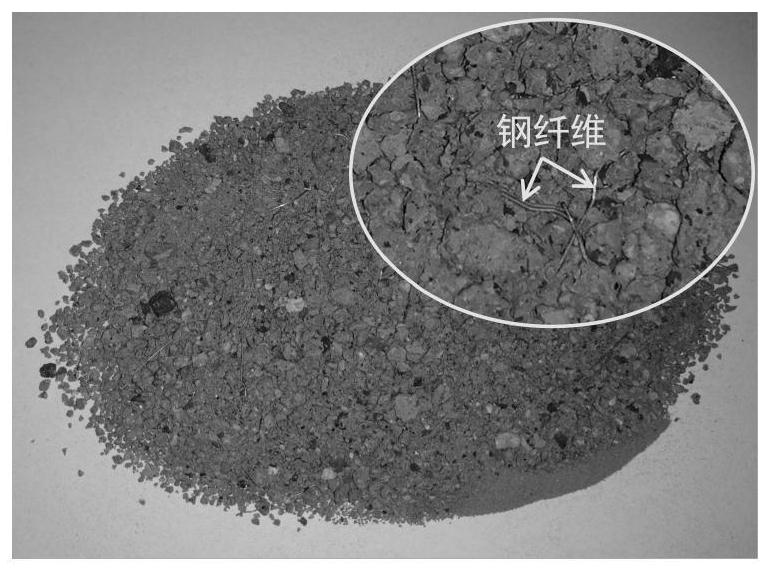

[0035] The dosage of ultra-high performance concrete cement, silicon ash, expander, water, sand, steel fiber and polycarboxylic acid superplasticizer was 758kg / m respectively 3 、191kg / m 3 、83kg / m 3 、213kg / m 3 、1032kg / m 3 、153kg / m 3 、32kg / m 3。 Cement, silicon ash, intuminant added to the Hobart stirrer stirred for 4min, the water reducer and water mixed evenly into the Hobart stirrer stirred for 8min, the steel fibers were added to the agitator in 6 times The process took 10min, and finally added sand to stir for 6min, poured into the mold, laminated maintenance 36h demoulding. The specimen after demolding is placed in clean water for maintenance for 1 day, the size of the anti-bending specimen is 40mm×40mm×160mm prism, and then the flexural test is carried out, the specimen after the test is pressurized and destroyed, the flexural strength of ultra-high-performance concrete is determined after the end of the test 1, the ultra-high-performance concrete after the strength test is so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com