A kind of MOFs material with high gas adsorption and its preparation method and application

A high adsorption, MOF technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of poor selective adsorption performance, poor gas adsorption performance, etc., and achieve the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

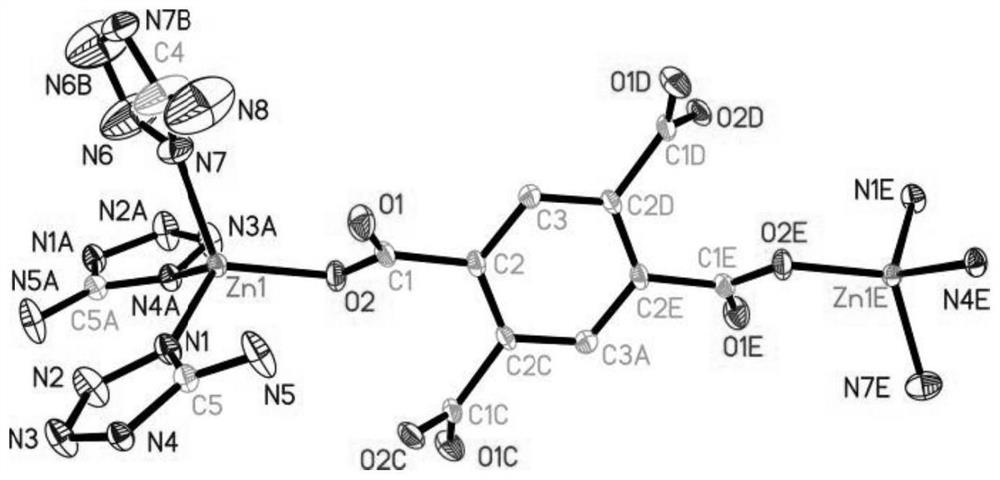

[0054] A kind of MOFs material with high gas adsorption of the present embodiment, such as figure 1 As shown, the molecular formula of its monomer molecule is C 8 h 18 N 15 Zn 2 o 9 , the molecular weight is 599.15, and the coordination formula is [Zn 2 (HATZ)(ATZ) 2 (PMA) 0.5 ]·(H 2 O) 5 , HATZ is 5-aminotetrazole, and PMA is pyromellitic acid; see Table 1 for crystal structure data, and see Table 2 for some bond length and bond angle data; each unit cell unit of the MOFs material The volume through which the solvent can pass is The porosity is 48.7%.

[0055] This embodiment also provides a method for preparing a MOFs material with high gas adsorption, specifically as follows:

[0056] Weigh analytically pure 5-aminotetrazole (0.5mmol, 0.043g), analytically pure pyromellitic acid (0.25mmol, 0.064g) and analytically pure Zn (CH 3 COO) 2 2H 2 O (0.5mmol, 0.110g) was placed in a 20mL reactor, 10mL of ultrapure water was added to stir and dissolve, then analytica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com