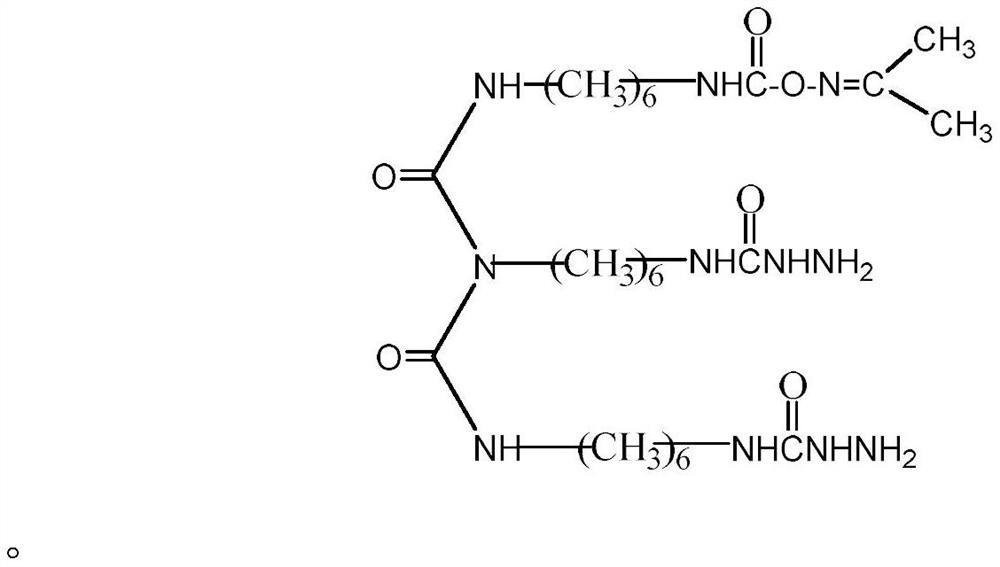

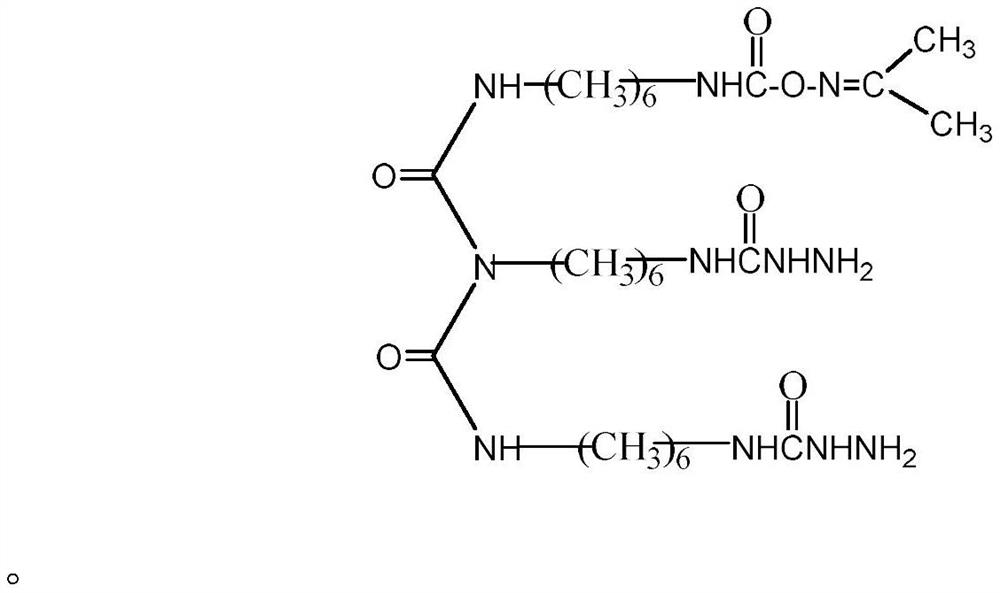

Washable and chlorine-resistant improver for nylon and nylon/spandex dyed fabric and preparation method of washable and chlorine-resistant improver

A technology of lifting agent and nylon, which is applied in the field of textile printing and dyeing auxiliaries, can solve the problems of infirmity and weak binding force, and achieve the effect of good washability and small color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

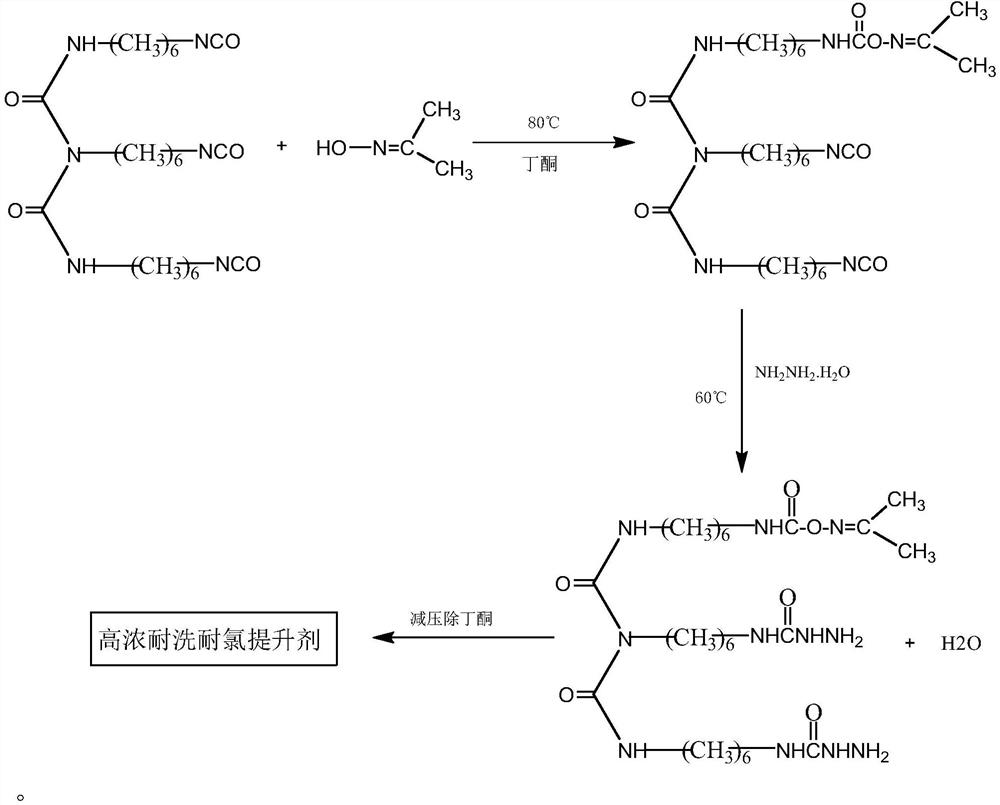

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a preparation method of a washable and chlorine-resistant enhancer for nylon, nylon / spandex dyed fabrics, comprising the following steps:

[0028] S1), each component of the present embodiment is as follows:

[0029]

[0030] S2), in a dry 1000L three-neck round bottom flask, add 450g of biuret triisocyanate, 395g of butanone and stir for 30 minutes, slowly add 85g of acetone oxime, react at 80°C for 4 hours, cool down to 60°C, add 70g of hydrated Hydrazine (80%) was reacted for 1 hour, and the butanone was removed by decompression and vacuum pumping to obtain the corresponding lifting agent.

Embodiment 2

[0032] S1), each component of the present embodiment is as follows:

[0033]

[0034] S2), in a dry 1000L three-neck round bottom flask, add 500g of biuret triisocyanate, 336g of butanone and stir for 30 minutes, slowly add 78g of acetone oxime, react at 80°C for 4 hours, cool to 60°C, add 86g of hydration Hydrazine (80%) was reacted for 1 hour, and the butanone was removed by decompression and vacuum pumping to obtain the corresponding lifting agent.

Embodiment 3

[0036] S1), each component of the present embodiment is as follows:

[0037]

[0038] S2), in a dry 1000L three-neck round bottom flask, add 550g of biuret triisocyanate, 250g of butanone and stir for 30 minutes, slowly add 129g of acetone oxime, react at 80°C for 4 hours, cool down to 60°C, add 71g of hydration Hydrazine (80%) was reacted for 1 hour, and the butanone was removed by decompression and vacuum pumping to obtain the corresponding lifting agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap