Oxygen-fuel combustion calcium aluminate furnace

An all-oxygen combustion, calcium aluminate technology, used in furnaces, charge materials, crucible furnaces, etc., can solve the problems of low utilization rate of fuel thermal efficiency of regenerative furnaces, waste of refractory materials and labor costs, unbearable for enterprises, etc. The effect of energy saving, improving thermal insulation effect, and saving enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

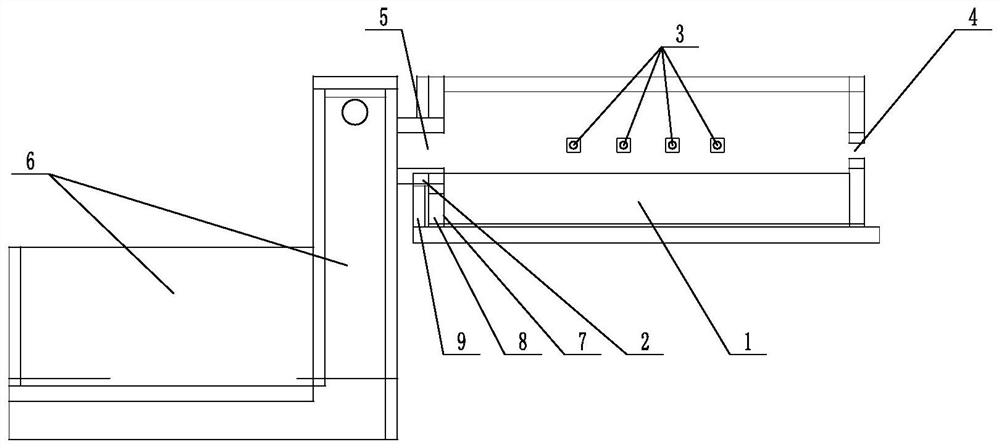

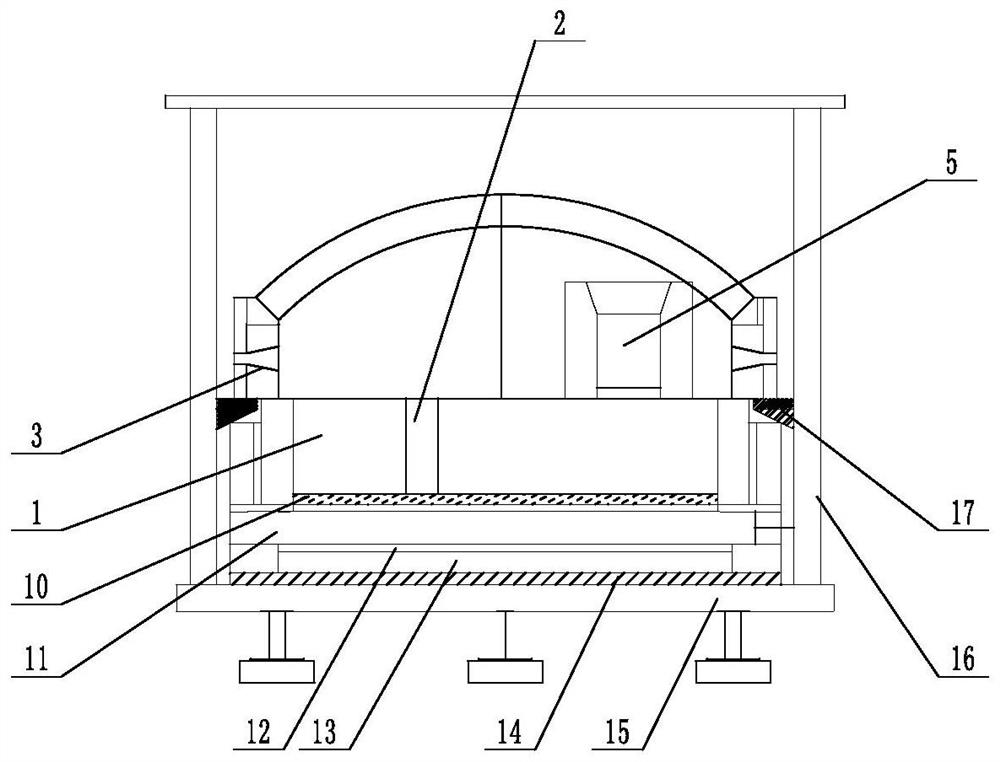

[0032] like figure 1 , 2 As shown in and 5, the oxy-fuel calcium aluminate furnace includes a furnace body and an oxy-fuel combustion device, the oxy-fuel combustion device is installed on the furnace body, and a melting pool 1 is arranged inside the furnace body, and the melting pool 1 One end of the furnace body is provided with a feeding port 4, the other end is provided with a discharge port 2 communicating with the outside world, and the smoke exhaust port 5 is arranged side by side with the discharge port 2, and multiple sets of burner ports are provided on the furnace body on both sides of the melting pool 1 3. The outlet end of the smoke exhaust port 5 is connected to the smoke exhaust and dust removal and cooling device 6, and the smoke exhaust and dust removal and cooling device 6 is composed of a smoke collecting pipe and a lye pool for dust removal and cooling; Fixedly connected to the melt clarification brick 7 inserted into the bottom of the melting pool 1, the ...

Embodiment 2

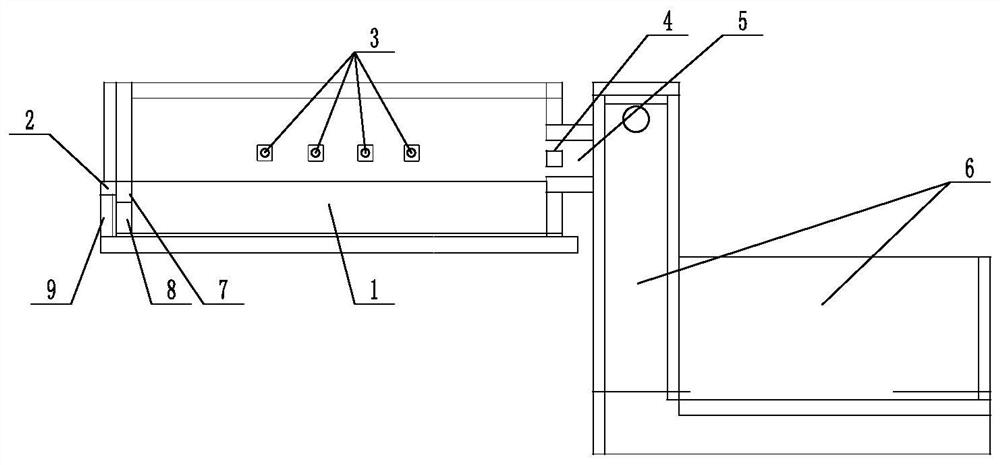

[0035] like Figure 3-5 As shown, the all-oxygen combustion calcium aluminate furnace includes a furnace body and an all-oxygen combustion device, the all-oxygen combustion device is installed on the furnace body, and a melting pool 1 is arranged inside the furnace body, and one end of the melting pool 1 is a furnace The body is provided with a feeding port 4, and the other end is provided with a discharge port 2 communicating with the outside world. The smoke exhaust port 5 is arranged side by side with the feeding port 4, and multiple groups of burner ports 3 are provided on the furnace body on both sides of the melting pool 1. The outlet end of the smoke exhaust port 5 is connected to the smoke exhaust and dust removal and cooling device 6, and the smoke exhaust and dust removal and cooling device 6 is composed of a smoke collecting pipe and an alkali solution pool to perform dust removal and cooling; the furnace body at the 2 outlets is fixedly connected and inserted To th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com